Work method of aluminum alloy tool bus duct machining equipment

A technology of processing equipment and working methods, which is applied in the direction of metal processing equipment, metal processing, metal processing machinery parts, etc., can solve the problems of difficulty in ensuring hole position accuracy, high drilling cost, and waste of working time for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

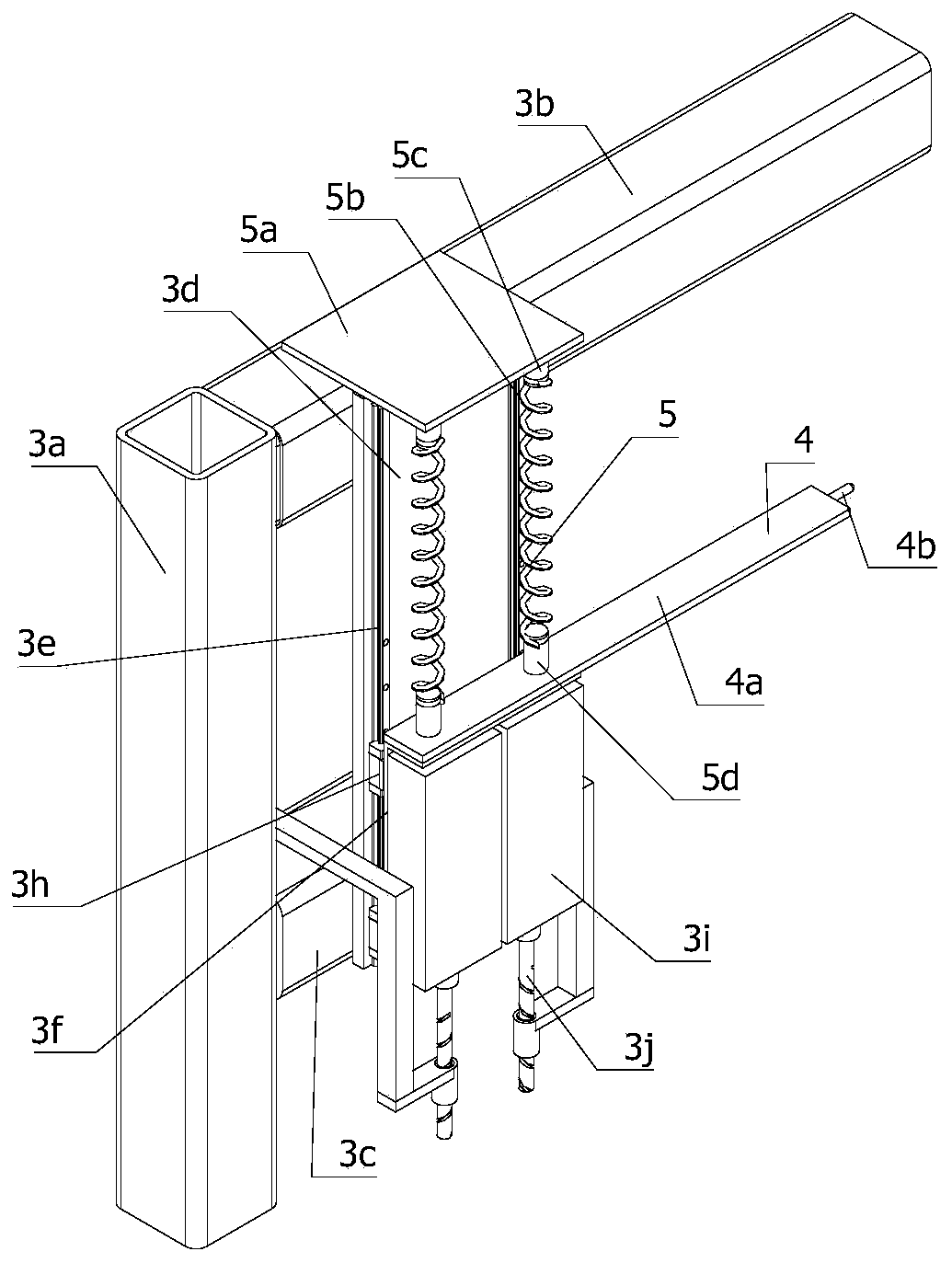

[0052] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0053] Wherein, the accompanying drawings are only for illustrative purposes, showing only schematic diagrams, rather than physical drawings, and should not be construed as limitations on this patent; in order to better illustrate the embodiments of the present invention, some parts of the accompanying drawings will be omitted, Enlarged or reduced, does not represent actual product size.

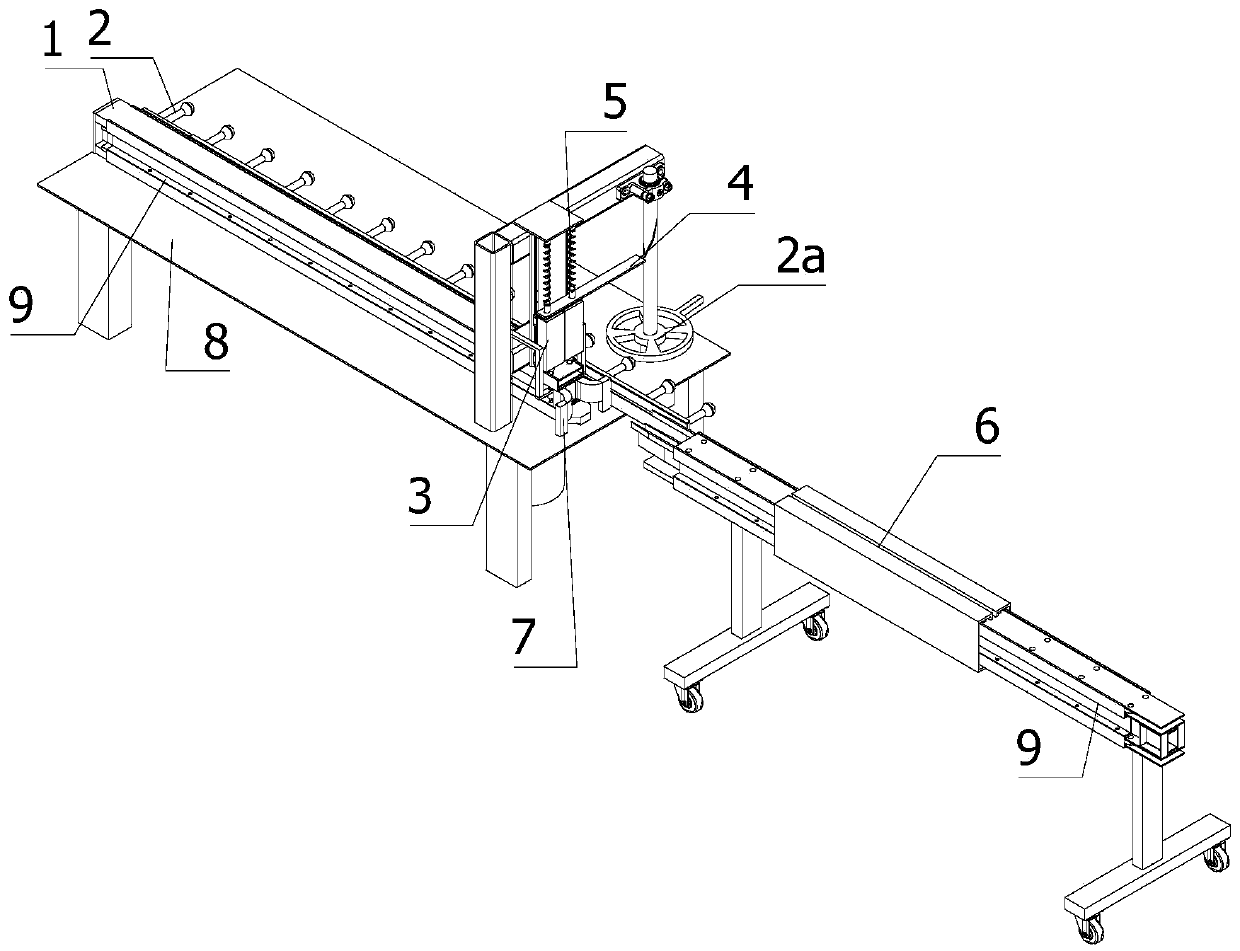

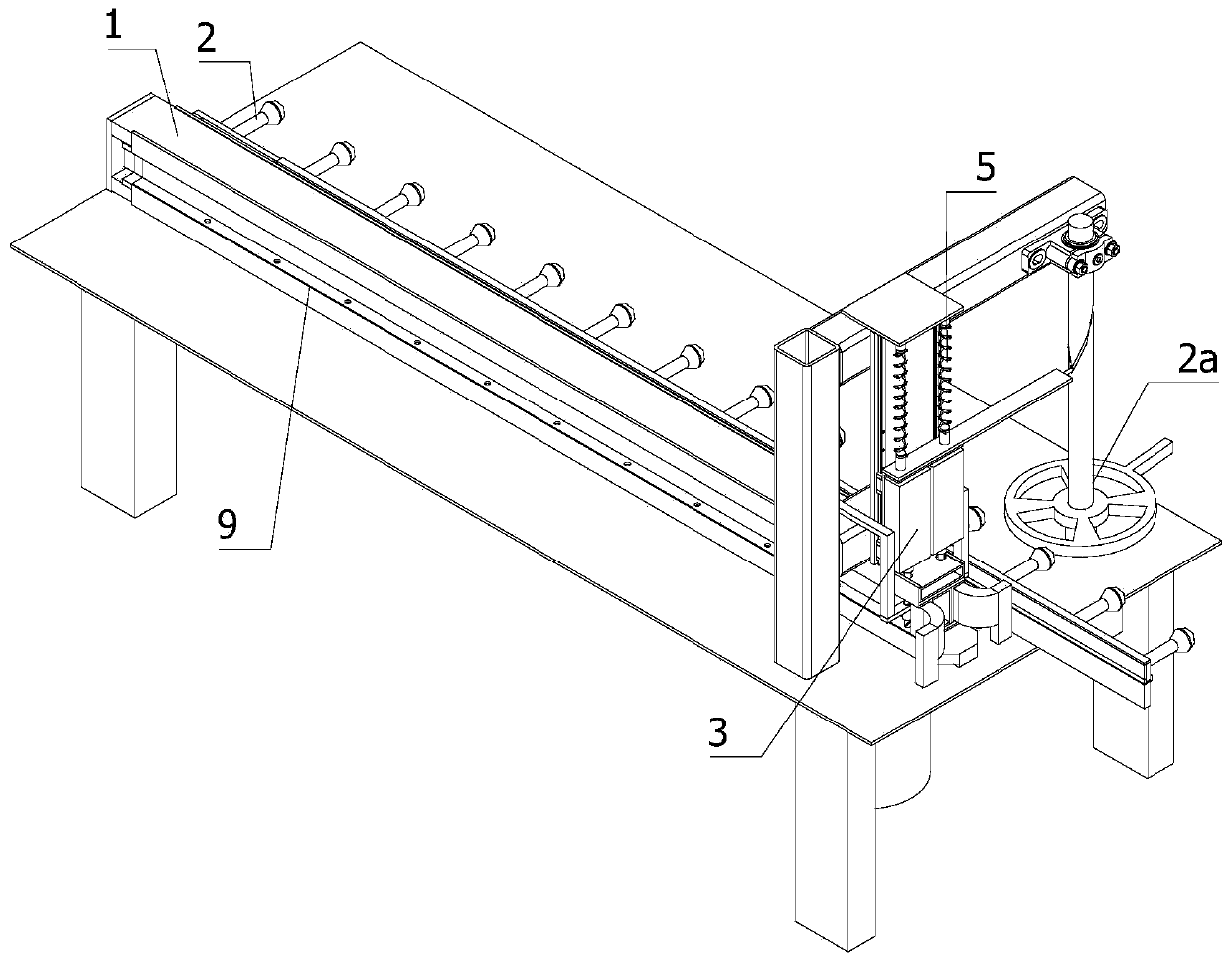

[0054] refer to Figure 1 to Figure 12 The shown aluminum alloy busway processing equipment includes a busway shell 9, and also includes a guide carriage 1, a horizontal pushing mechanism 2, a drilling mechanism 3, an up and down driving mechanism 4, a weight reducing mechanism 5, and a feeding mechanism 6 , the drill cuttings cleaning mechanism 7 and the support platform 8, the support platform 8 is fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com