Sliding block provided with inclined top and used for demolding

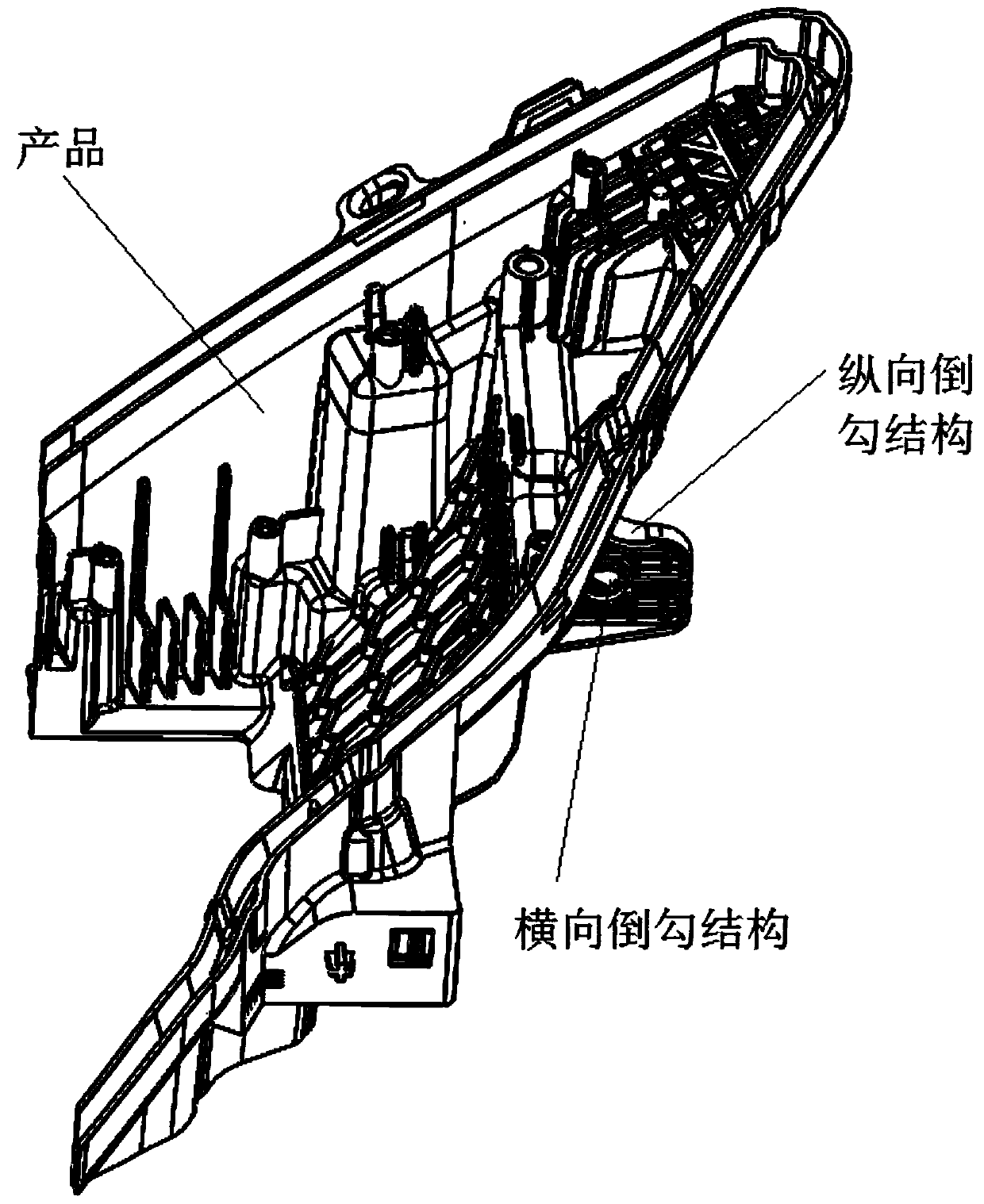

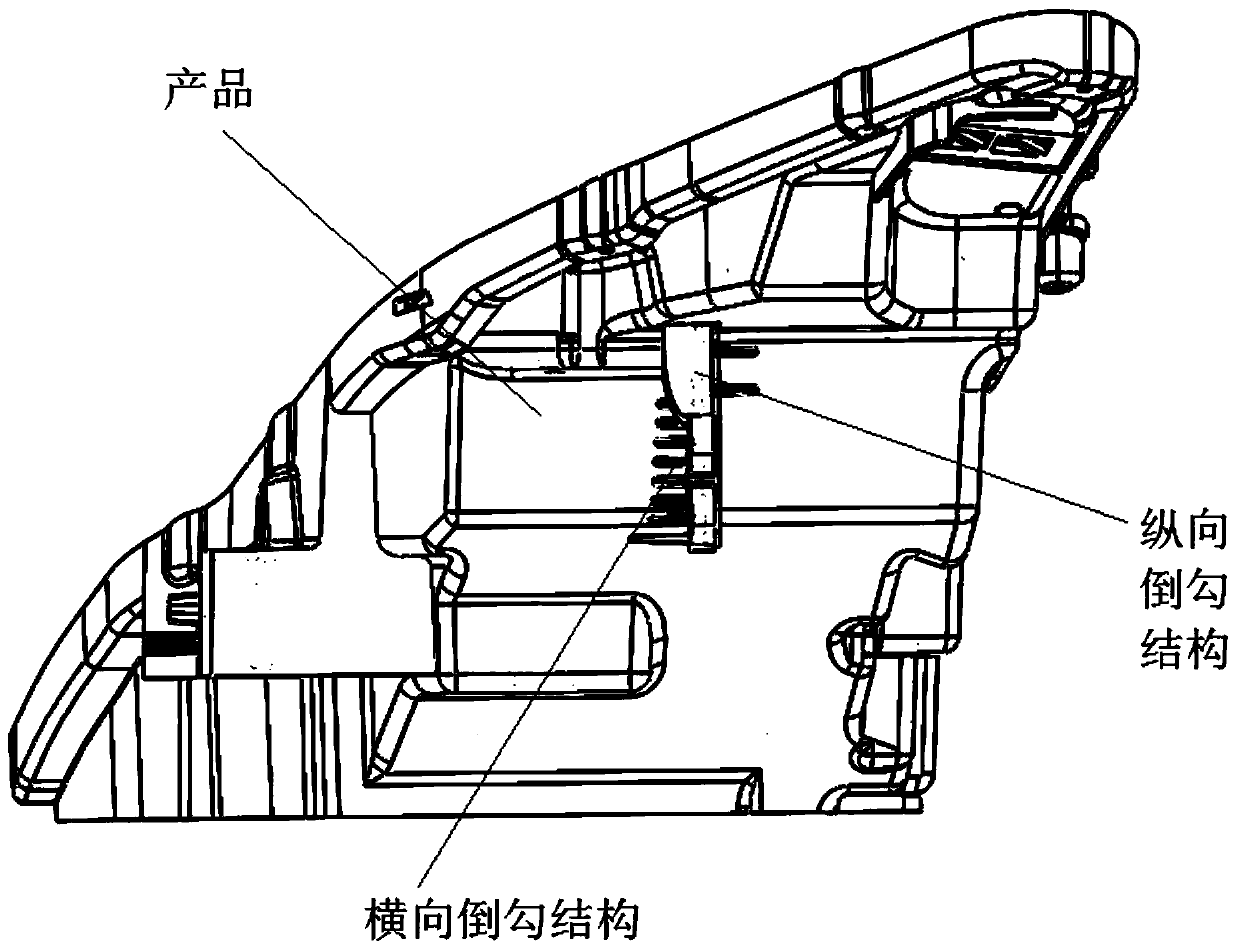

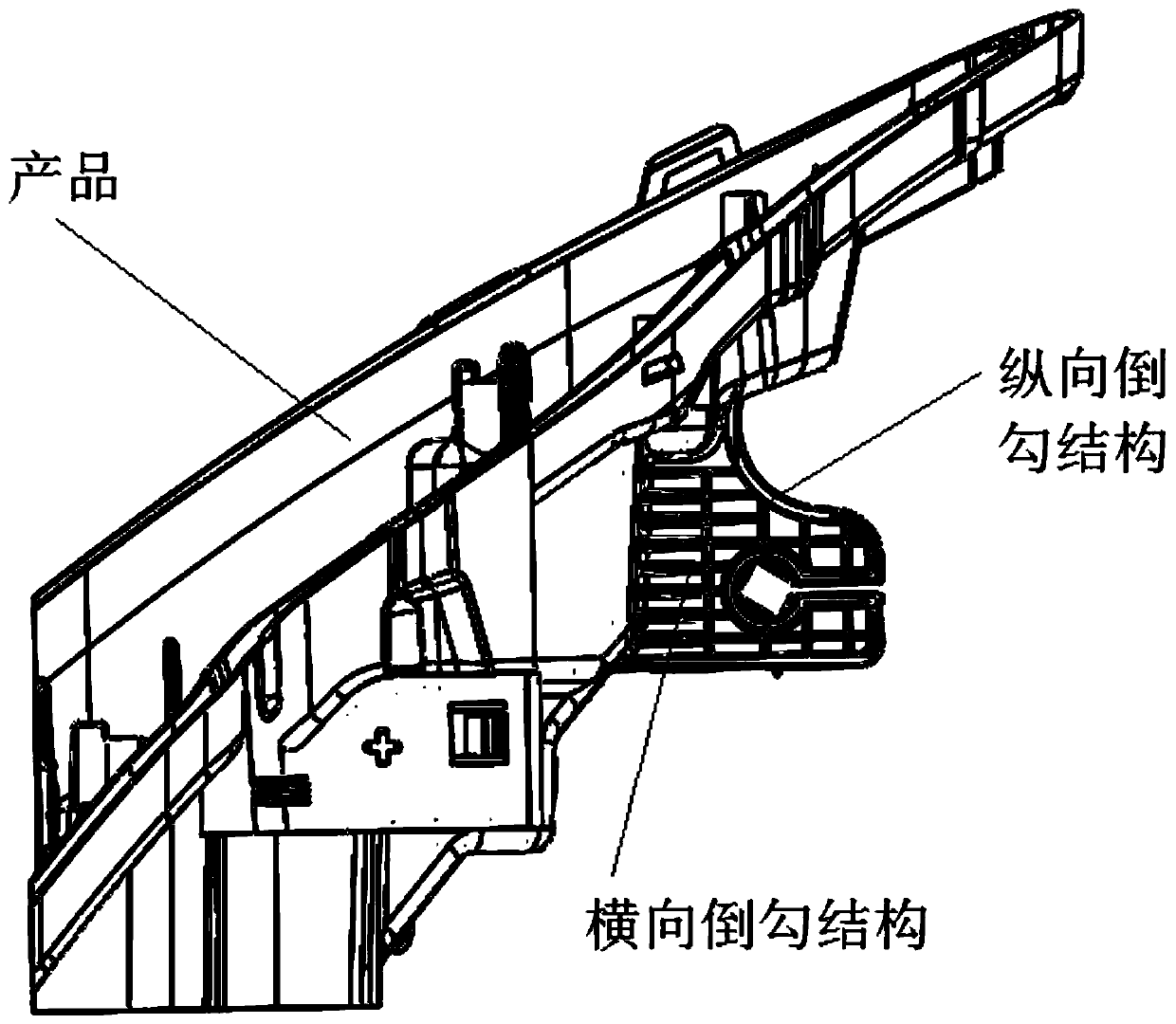

A sloping top and sliding block technology, applied in the field of auto parts processing, can solve the problems of contact damage of mold undercut structure, increase mold opening process, reduce production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0040] see Figure 4 to Figure 14 , a slide block for demoulding with a sloped roof according to a preferred embodiment of the present invention, comprising a slide block 1, a slope guide post 2, a pressing block 3, and a slope top inner core 4, the slide block 1 consists of a front slide block 16 and the rear slider 17 are connected, the front slider 16 and the rear slider 17 are fixedly connected by screws, and the front slider 16 is provided with a rightward inclined inclined top limit groove 19 in the horizontal direction, and the inclined top limit groove The left side of 19 is provided with a slanted top slanted arm abdication groove 15 in the vertical direction, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com