High-thermal-conductivity graphene composite material and preparation method thereof

A technology of high thermal conductivity graphite and composite materials, applied in the field of high thermal conductivity graphene composite materials and its preparation, can solve problems such as inability to meet heat dissipation or heating, low thermal conductivity, and inability to replace metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

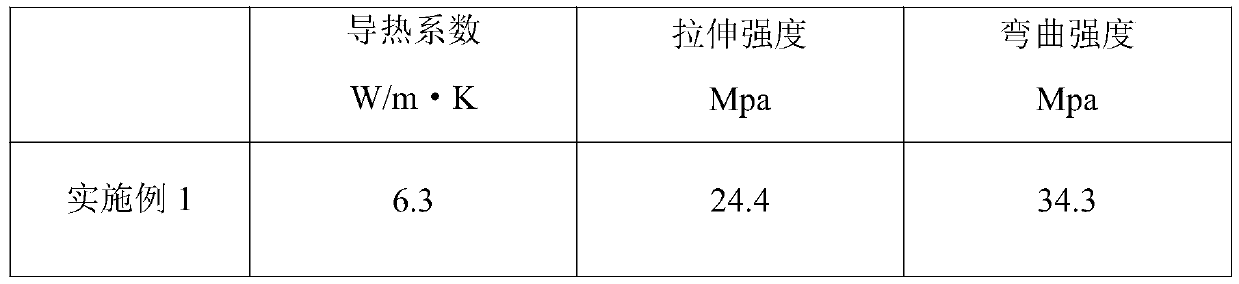

[0042] Example 1:

[0043] A high thermal conductivity graphene composite material, made of raw materials including the following parts by weight:

[0044] 30 parts of polypropylene powder, 12 parts of graphene, 22 parts of thermally conductive filler, 2 parts of dispersant, 3 parts of glass fiber, 4 parts of maleic anhydride grafted polypropylene;

[0045] The thermally conductive filler is at least one of aluminum oxide, graphite powder, boron nitride, aluminum nitride and aluminum powder.

[0046] In this embodiment, the thermally conductive filler is a mixture of aluminum oxide, aluminum nitride and aluminum powder.

[0047] In this embodiment, the thermally conductive filler is a mixture of aluminum oxide, aluminum nitride, and aluminum powder. The thermally conductive filler is aluminum oxide, aluminum nitride, and aluminum powder in a mass ratio of 10:18: 6.

[0048] In this embodiment, the thermal conductivity of the aluminum nitride is 260 w / m·k.

[0049] In this embodiment, the...

Example Embodiment

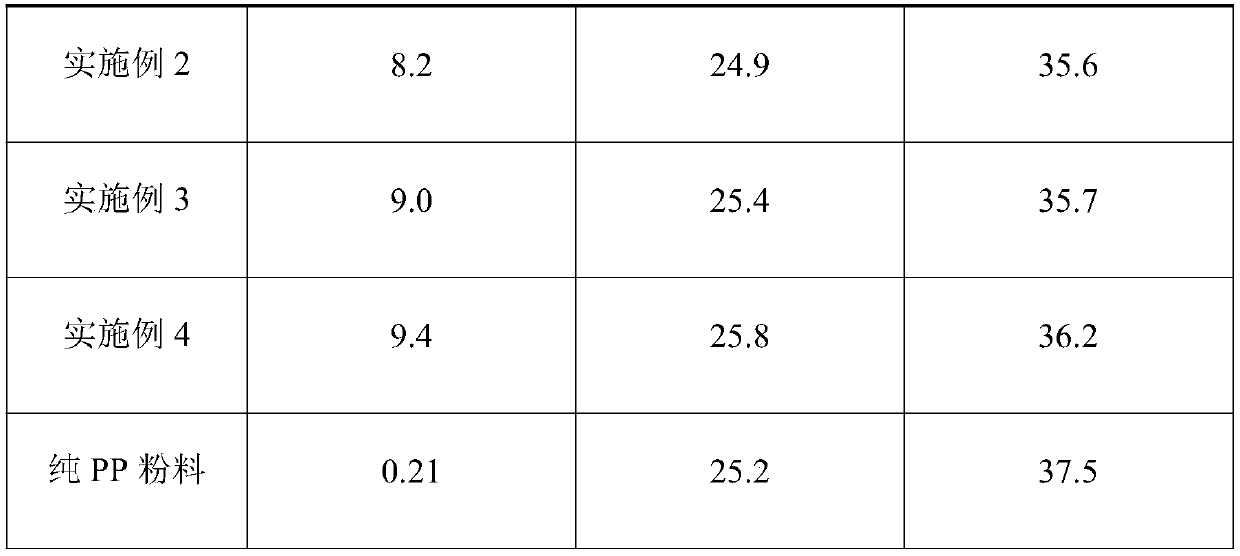

[0056] Example 2:

[0057] A high thermal conductivity graphene composite material, made of raw materials including the following parts by weight:

[0058] 45 parts of polypropylene powder, 22 parts of graphene, 12 parts of thermally conductive filler, 3 parts of dispersant, 4 parts of glass fiber, 7 parts of maleic anhydride grafted polypropylene;

[0059] The thermally conductive filler is at least one of aluminum oxide, graphite powder, boron nitride, aluminum nitride and aluminum powder.

[0060] In this embodiment, the thermally conductive filler is a mixture of aluminum oxide, aluminum nitride and aluminum powder.

[0061] In this embodiment, the thermally conductive filler is a mixture of aluminum oxide, aluminum nitride and aluminum powder. The thermally conductive filler is aluminum oxide, aluminum nitride and aluminum powder in a mass ratio of 10:21: 7.5.

[0062] In this embodiment, the thermal conductivity of the aluminum nitride is 280 w / m·k.

[0063] In this embodiment, the...

Example Embodiment

[0070] Example 3:

[0071] A high thermal conductivity graphene composite material, made of raw materials including the following parts by weight:

[0072] 38 parts of polypropylene powder, 17 parts of graphene, 20 parts of thermally conductive filler, 2.5 parts of dispersant, 3.5 parts of glass fiber, 5.6 parts of maleic anhydride grafted polypropylene;

[0073] The thermally conductive filler is at least one of aluminum oxide, graphite powder, boron nitride, aluminum nitride and aluminum powder.

[0074] In this embodiment, the thermally conductive filler is a mixture of aluminum oxide, aluminum nitride and aluminum powder.

[0075] In this embodiment, the thermally conductive filler is a mixture of aluminum oxide, aluminum nitride, and aluminum powder. The thermally conductive filler is aluminum oxide, aluminum nitride and aluminum powder in a mass ratio of 10:19.5: 6.8.

[0076] In this embodiment, the thermal conductivity of the aluminum nitride is 270 w / m·k.

[0077] In this embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com