Assembly type T beam for tensioning circular corrugated pipe hogging moment steel bundle on bridge floor

A negative bending moment and bellows technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of inability to use small-radius curved bridges, affecting beam penetration, and affecting structural durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

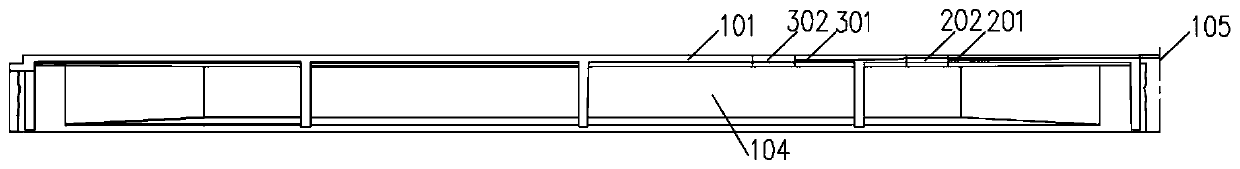

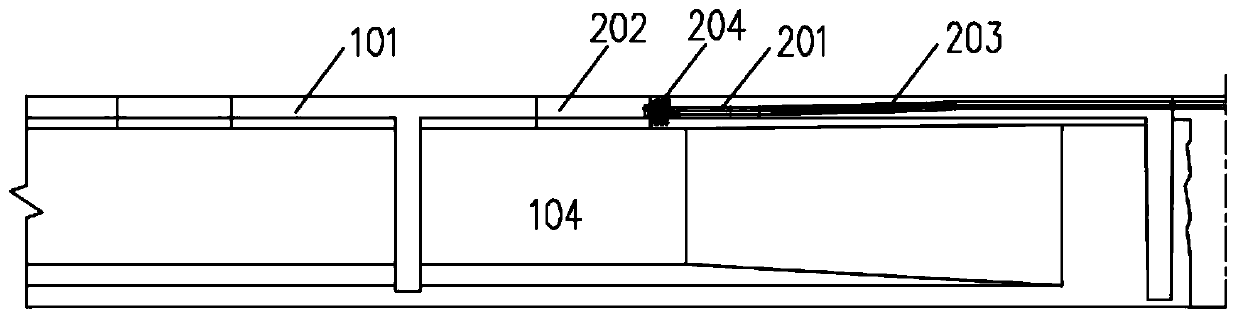

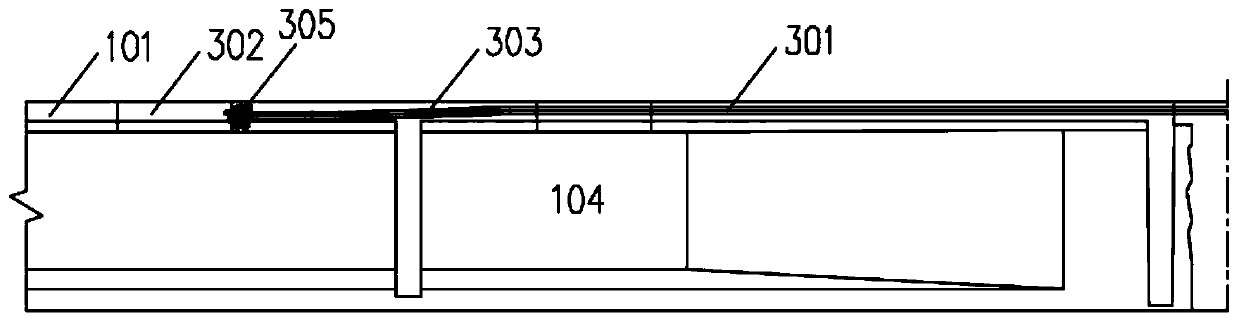

[0034] Such as Figure 1-6 As shown, a prefabricated T-beam in which circular bellows negative bending moment steel beams are stretched on the bridge deck includes a connected T-beam web 104 and a T-beam flange 101; inside the T-beam flange 101 is a circular The bellows negative bending moment steel beam 201 and the outer circular bellows negative bending moment steel beam 301, the outer circular bellows negative bending moment steel beam 301 is located on both sides of the inner circular bellows negative bending moment steel beam 201; T beam flange plate The top of 101 is reserved with an inner negative bending moment steel beam tensioning notch 202 corresponding to the inner circular bellows negative bending moment steel beam 201 and an outer negative bending slot corresponding to the outer circular bellows negative bending moment steel beam 301. Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com