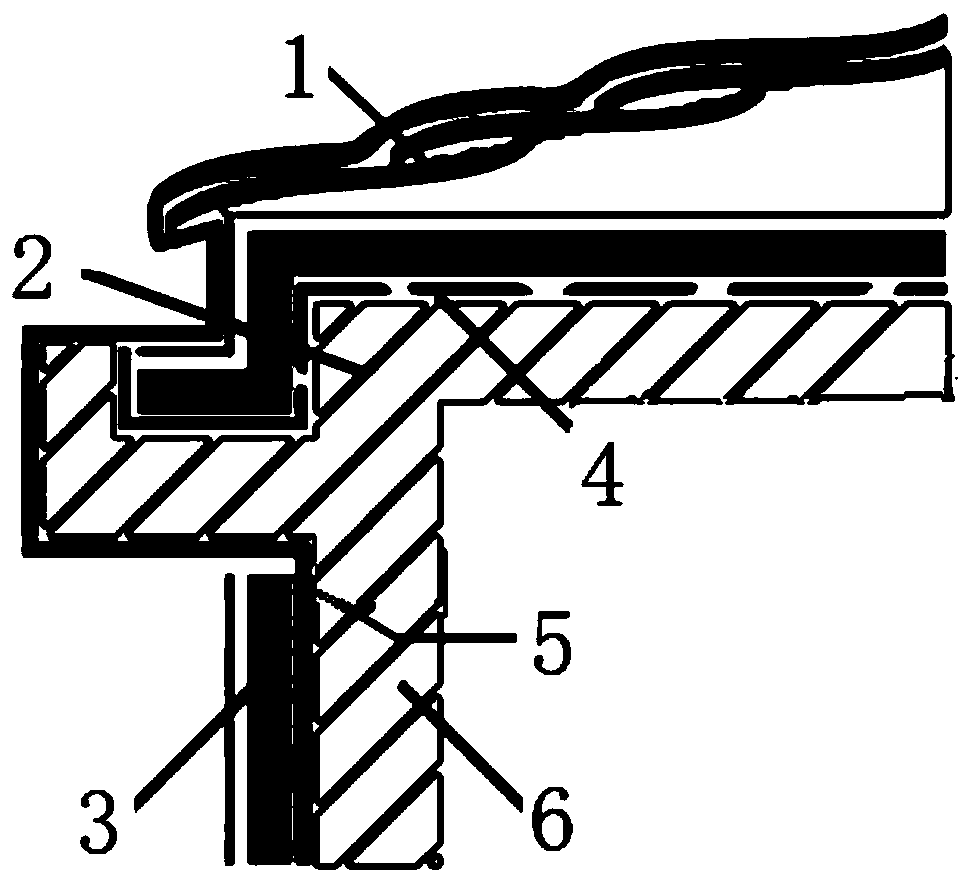

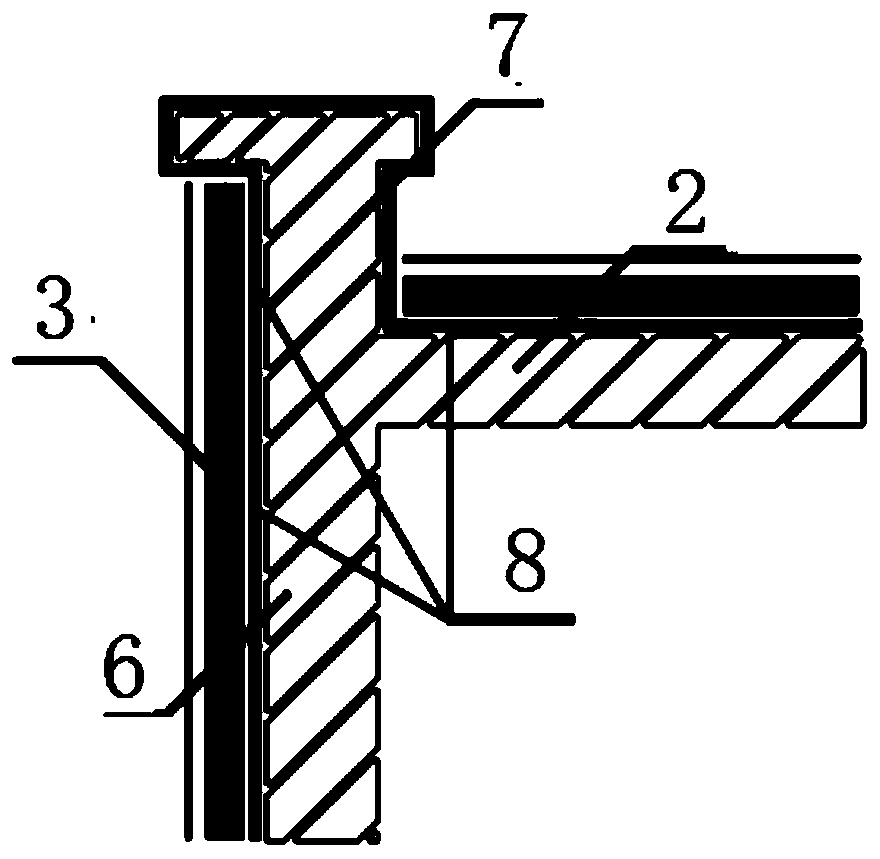

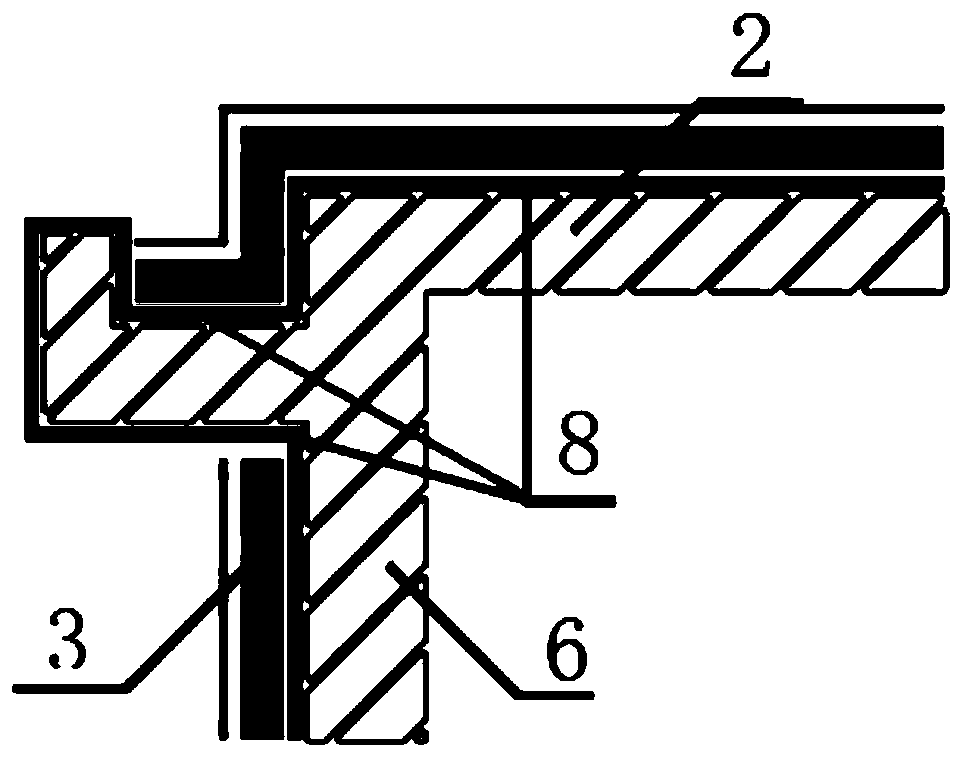

360-degree full-sealed waterproof integrated treatment method

A treatment method and fully-sealed technology, applied in the field of 360° fully-sealed and waterproof integrated treatment, can solve the problems of unsafe life of construction workers and residents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: The long-short filament blended fiber cloth comprises a first base fabric layer and a second base fabric layer, and the first base fabric layer is formed by weaving warp threads of long filaments and weft threads of short filaments. The second base cloth layer is formed by weaving the warp threads of the short fiber filaments and the weft threads of the long fiber filaments, the first base cloth layer and the second base cloth layer are connected as a whole by a corrosion-resistant adhesive, and the surface is coated with A flame retardant coating, the flame retardant coating is a polytetrafluoroethylene coating. The monofilament fiber cloth has poor tensile deformation resistance. When it is stretched by an external force, although it will not break, it will be pulled and deformed, and local wrinkles will appear, which is not conducive to maintaining the overall flatness of the waterproof layer during construction. The single-short-filament fiber cloth ha...

Embodiment 2

[0046] Embodiment 2: The long-short filament blended fiber cloth comprises a first base fabric layer and a second base fabric layer, and the first base fabric layer is formed by mixing single warp fiber filaments and double weft fiber short filaments, so The second base fabric layer is made of single-warp short fiber and double-weft fiber filament, and the first base fabric layer and the second base fabric layer are connected as a whole by a corrosion-resistant adhesive viscose and then coated with A flame retardant coating, the flame retardant coating is a polytetrafluoroethylene coating. Using two parallel double warp / double weft threads and single weft / single warp threads to weave each other up and down can reduce the linear density and thickness of the interweaving points of warp and weft threads. The monofilament fiber cloth has poor tensile deformation resistance. When it is stretched by an external force, although it will not break, it will be pulled and deformed, and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spray thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com