Boiler and the Method for Controlling Combustion of the Boiler

A control method and boiler technology, which are applied in the combustion method, control combustion, and regulate fuel supply, etc., can solve the problems of reduced boiler efficiency, blockage of exhaust flue, and inability to discharge combustion gas smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

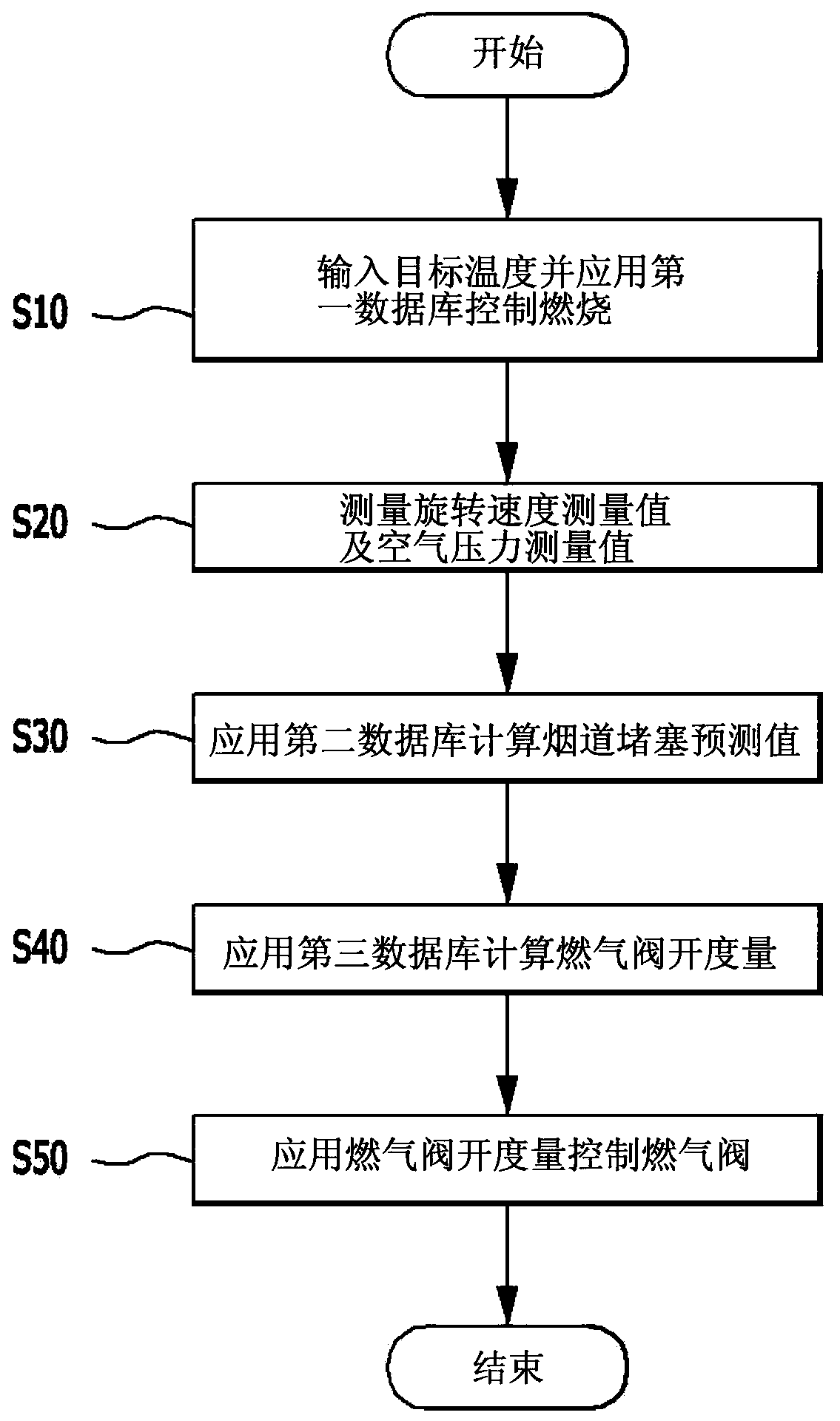

[0040] Hereinafter, a combustion control method for a boiler according to the present invention will be described in detail with reference to the drawings.

[0041] Here, a detailed description of content overlapping with the content described in the prior art will be omitted, and the description will focus on newly added components in the present invention.

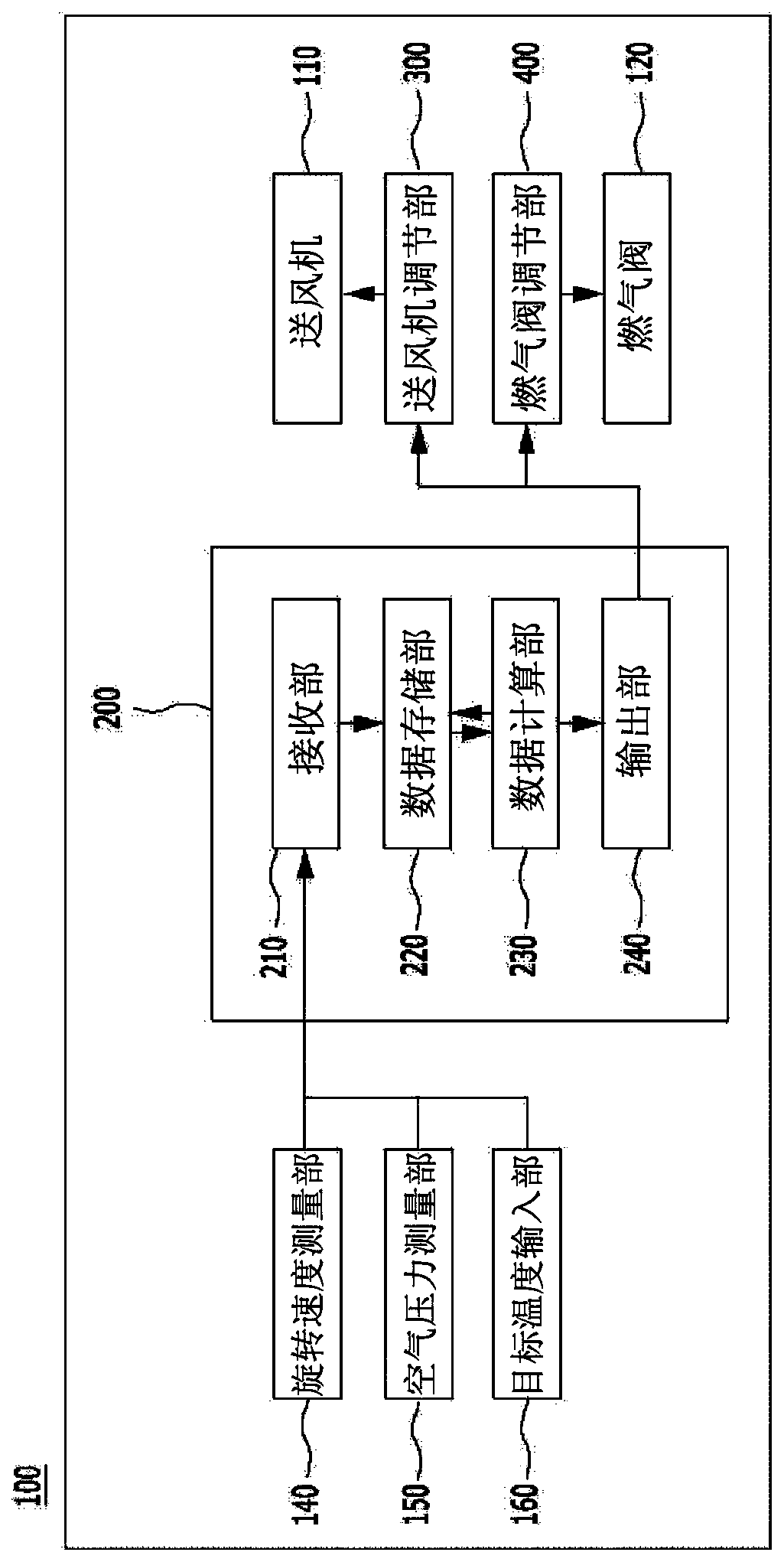

[0042] refer to figure 1 According to the boiler 100 of the present invention, the boiler 100 includes: a blower 110 that rotates to allow air and gas to flow in; a gas valve 120 that adjusts the degree of opening and closing of a gas supply pipe (not shown) that flows into the gas; a burner (not shown) that makes Combustion of gas; flue (not shown), discharge combustion gas; control unit 200, controls the air blower 110 and the gas valve 120 to adjust the amount of air and gas supplied to the burner.

[0043] In addition, a target temperature input unit 160 for inputting a target temperature of heating or hot water to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com