Stirring type mixed gas pressure tank for laser switch

A mixed gas and laser switching technology, applied in the field of X-ray machines, can solve problems such as sealing problems, increased probability of self-breakdown, difficulty in maintaining the consistency of gas ratio between multiple shots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

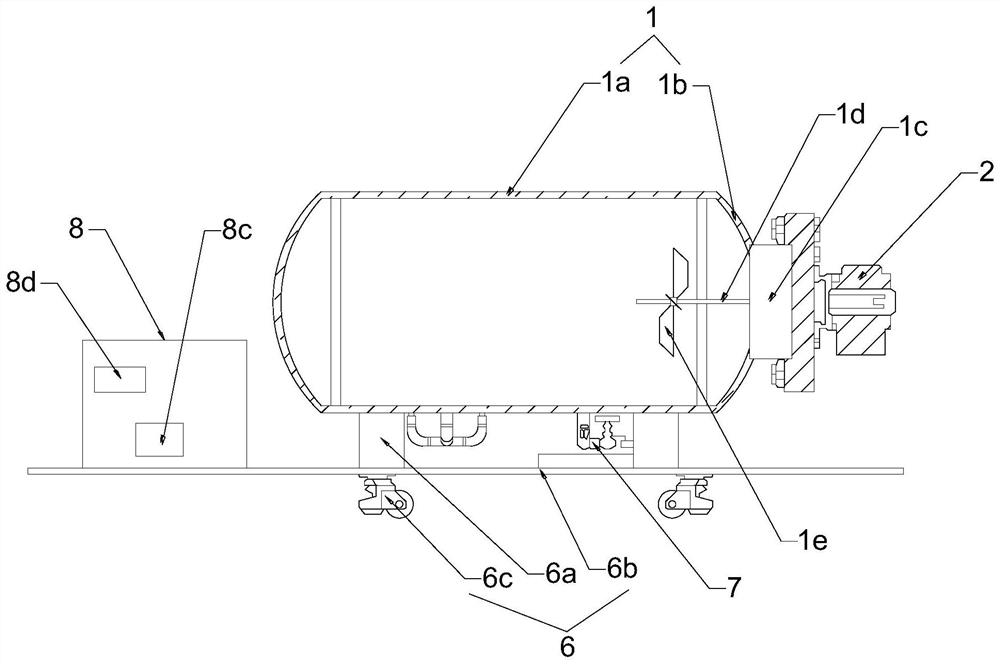

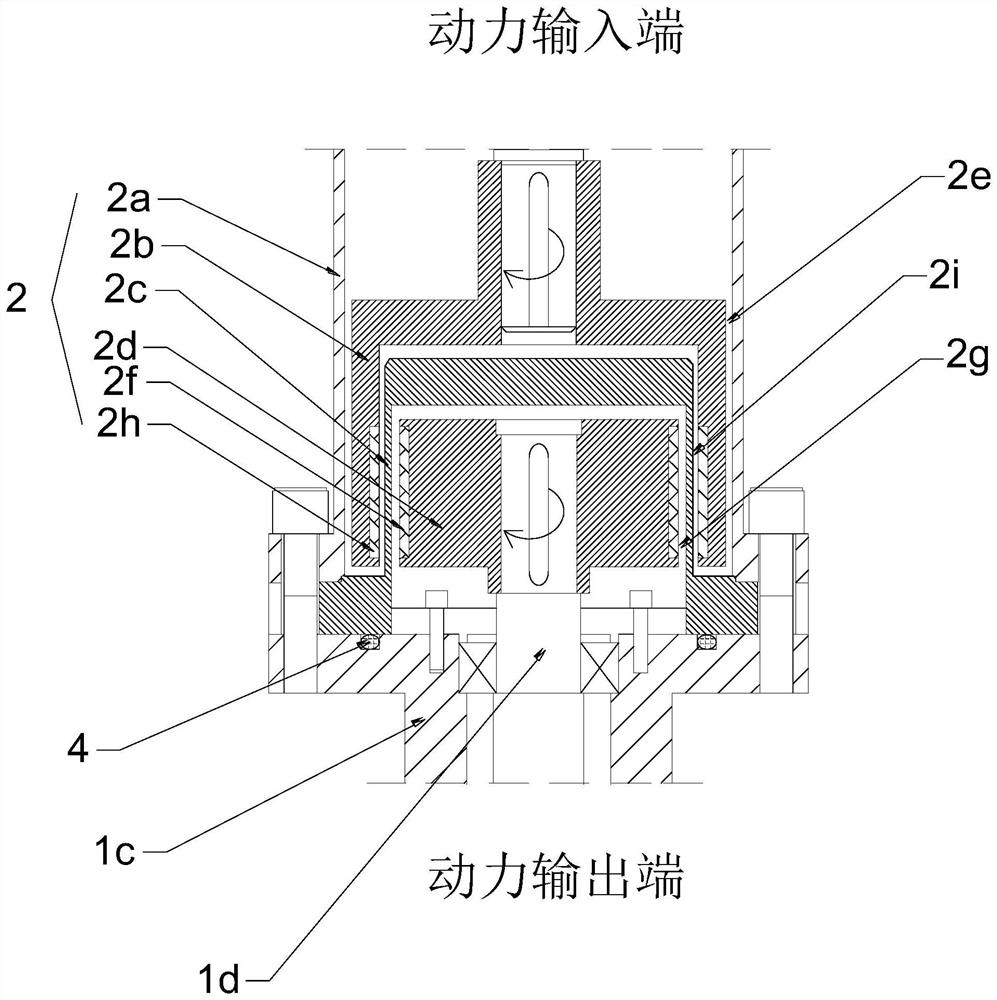

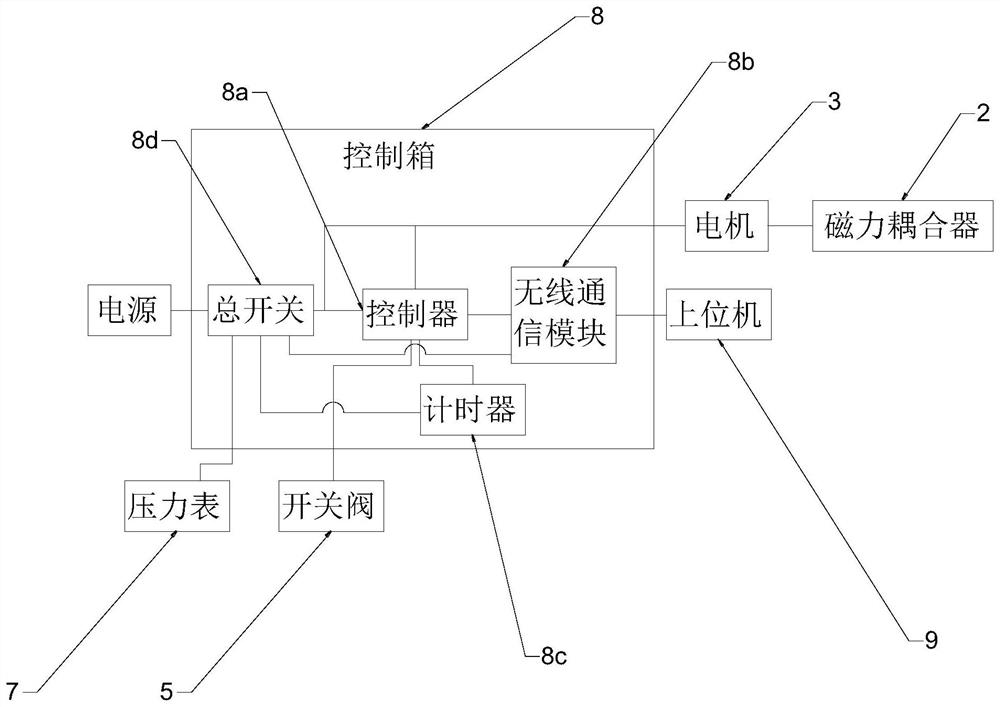

[0037] A stirred mixed gas pressure tank for laser switches, comprising a pressure tank 1 for storing mixed gas, the pressure tank 1 comprising a tank body 1a and a cover body 1b, and the cover body 1b is far away from the tank body 1a One side is provided with flange 1c, and described flange 1c is provided with magnetic coupler 2, and described tank body 1a is provided with stirring shaft 1d and stirring paddle 1e, and the power input end of described magnetic coupler 2 is connected with The motor 3 is connected, the power output end of the magnetic coupler 2 is connected with the stirring shaft 1d, the tank body 1a is provided with an air charging port and an exhaust port, and the exhaust port is connected with the X-ray machine through a pipeline, The inflation port is respectively connected with different gas sources through several pipelines.

[0038] In this technical solution, the unused gas source is charged through the gas charging port, the stirring shaft is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com