Maskless photoetching system and image surface focus real-time detection method

A maskless lithography and lithography technology, applied in the field of lithography, can solve problems affecting the yield of the production process, defocused imaging, and decreased focus accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

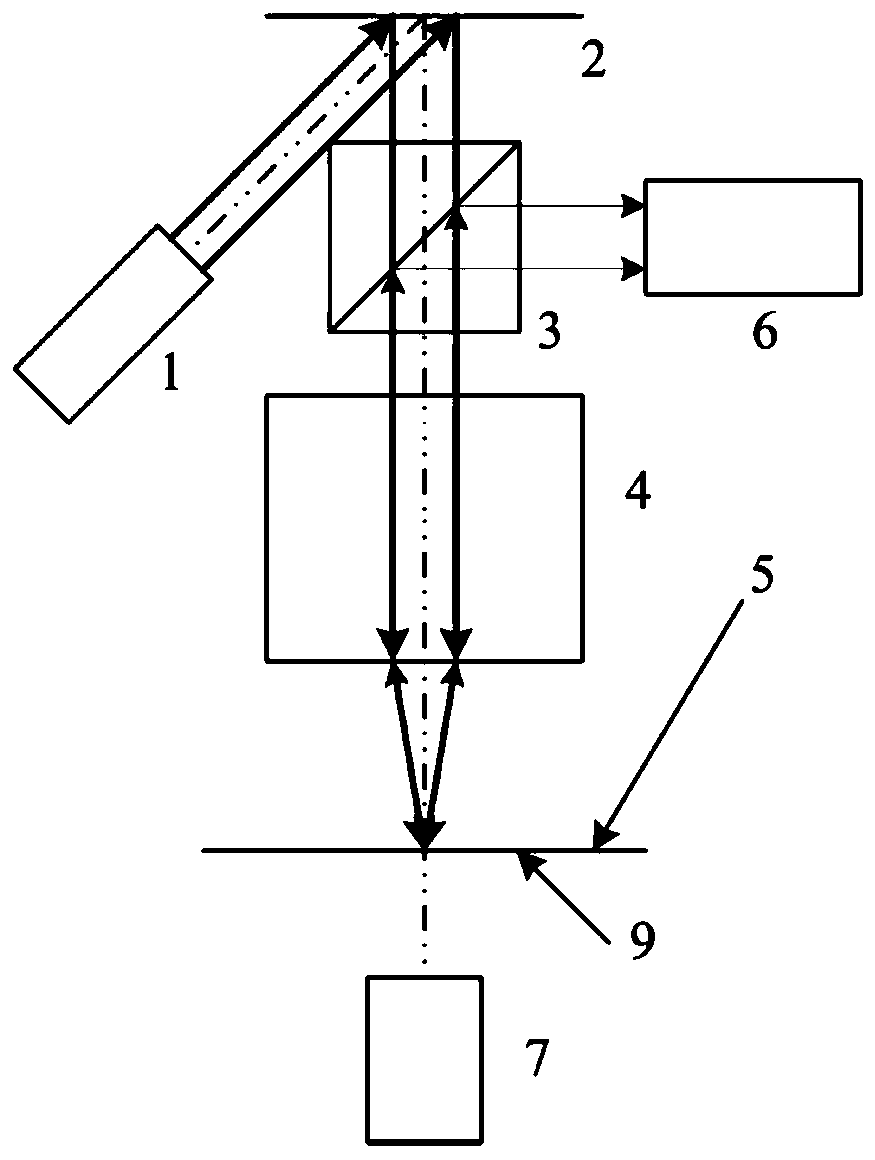

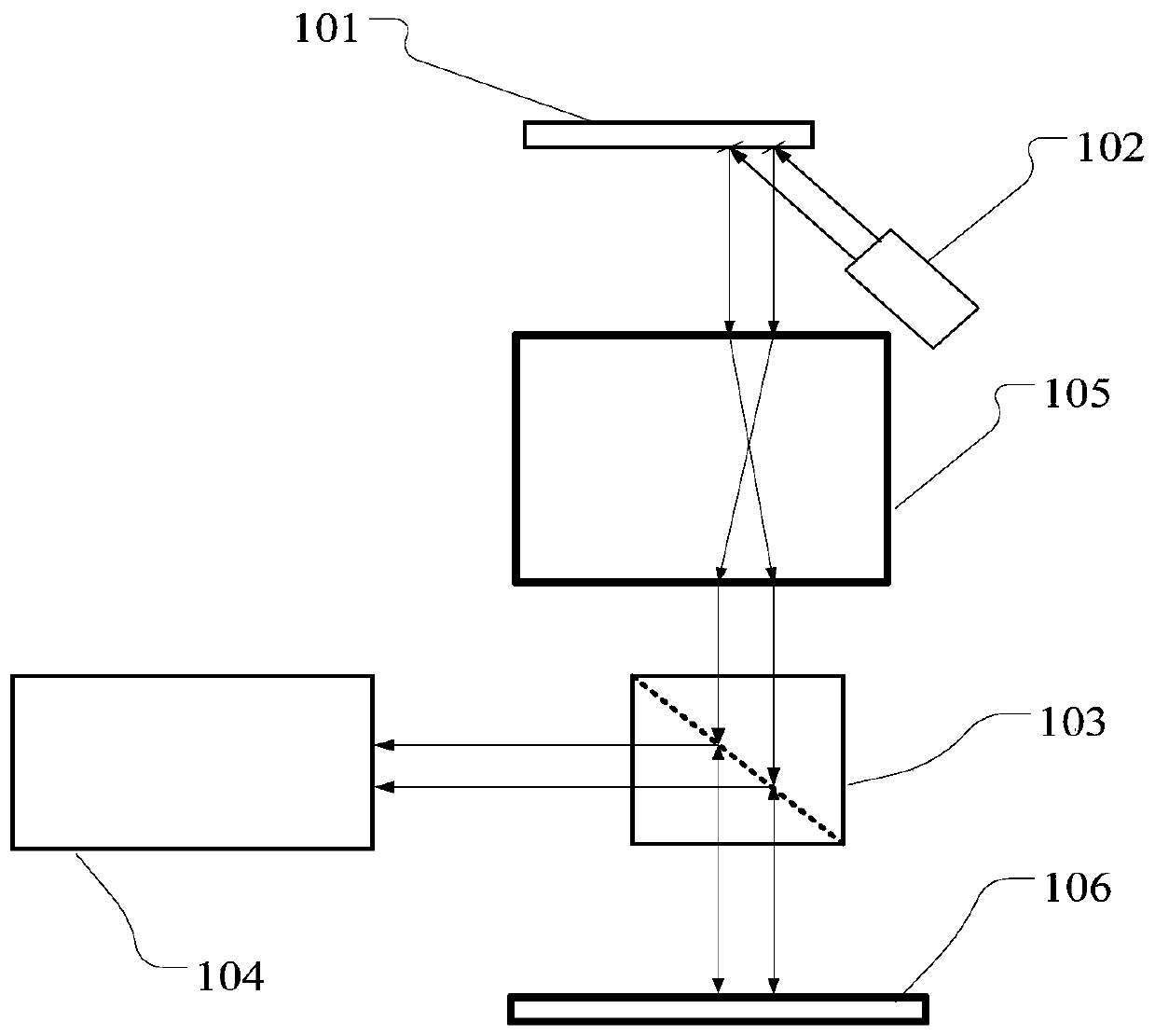

[0049] As shown in the figure, the maskless lithography system according to an embodiment of the present invention includes: a DMD module 101 , an illumination module 102 , a spectroscopic mirror group 103 , a focal plane detection camera module 104 and a lithography lens 105 . DMD module 101, lighting module 102, spectroscopic mirror group 103, focal plane detection camera module 104 and lithography lens 105 all can adopt any suitable structure, size and mode of operation, can be a single part, also can be many components composed of parts.

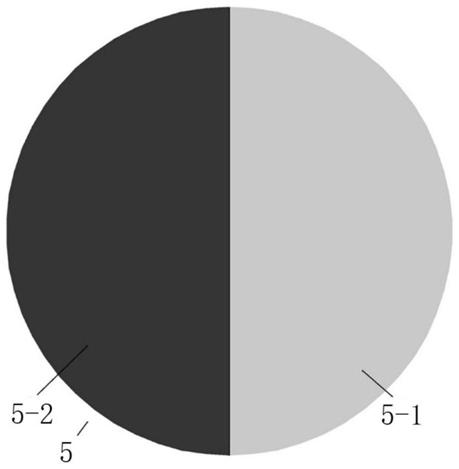

[0050] The DMD module 101 is used to emit light beams to form specific patterns. Usually the DMD module 101 is controlled by a control system to form a specific pattern; it can also have a control system itself. see Figure 5 , the DMD module 101 has a first area 101-1 for lithographic imaging, and a second a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com