Corrosion-resistant steel material for deck plate and bottom plate of crude oil tanker and crude oil tanker

A crude oil tanker and corrosion-resistant technology, applied in the field of crude oil tanks, can solve the problems of oil coating detachment, inspection, and coating costing huge costs and expanding coating area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

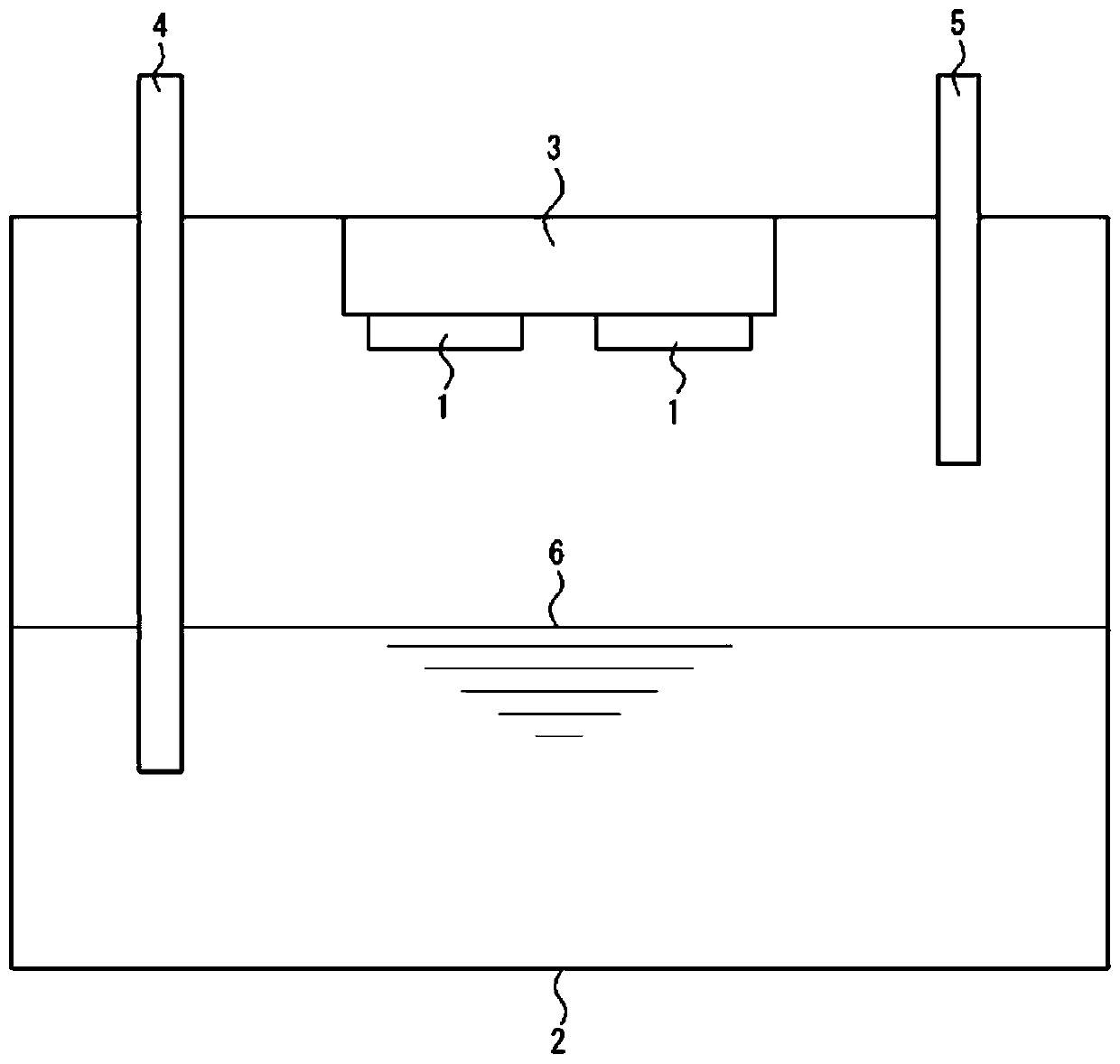

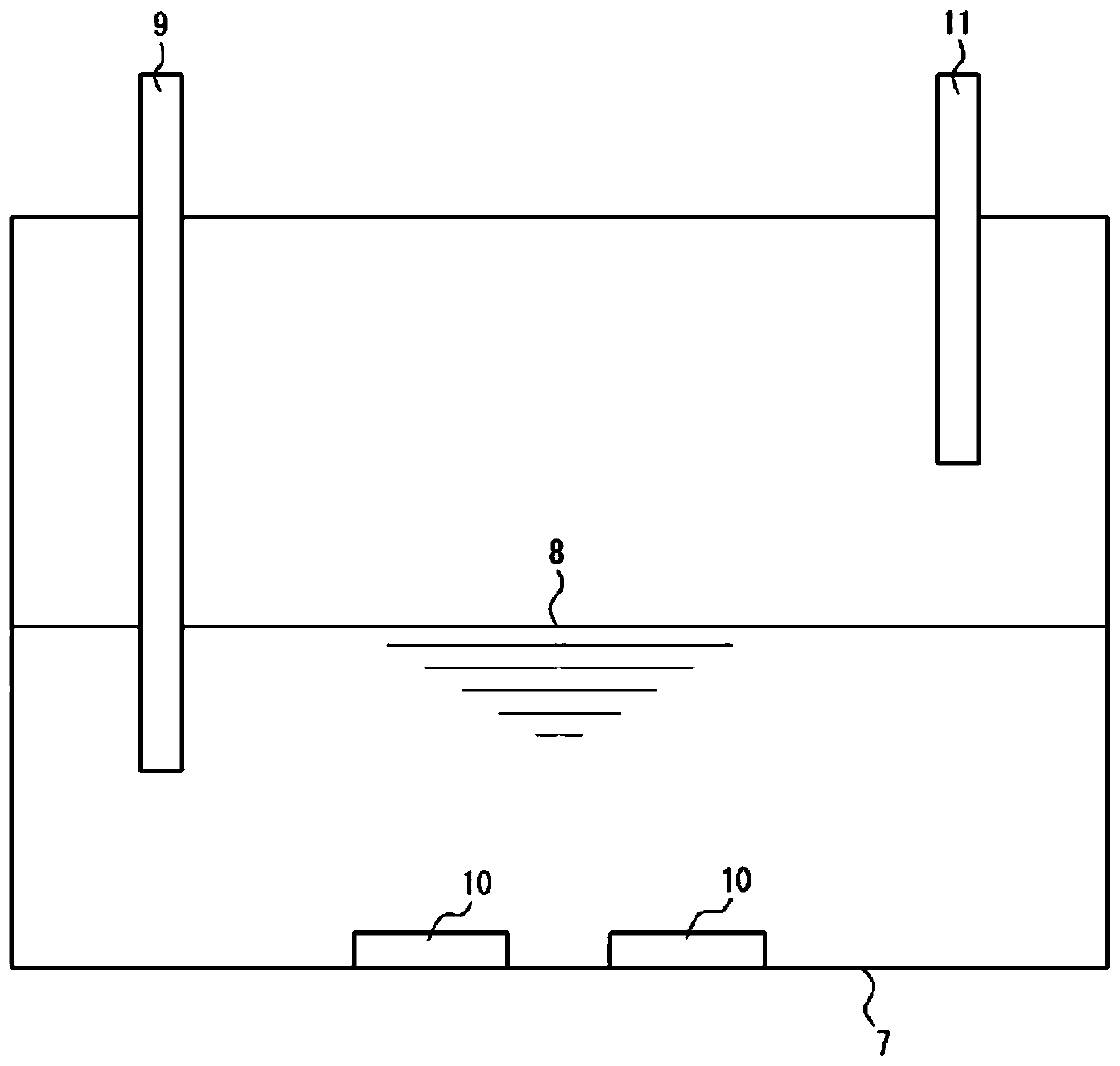

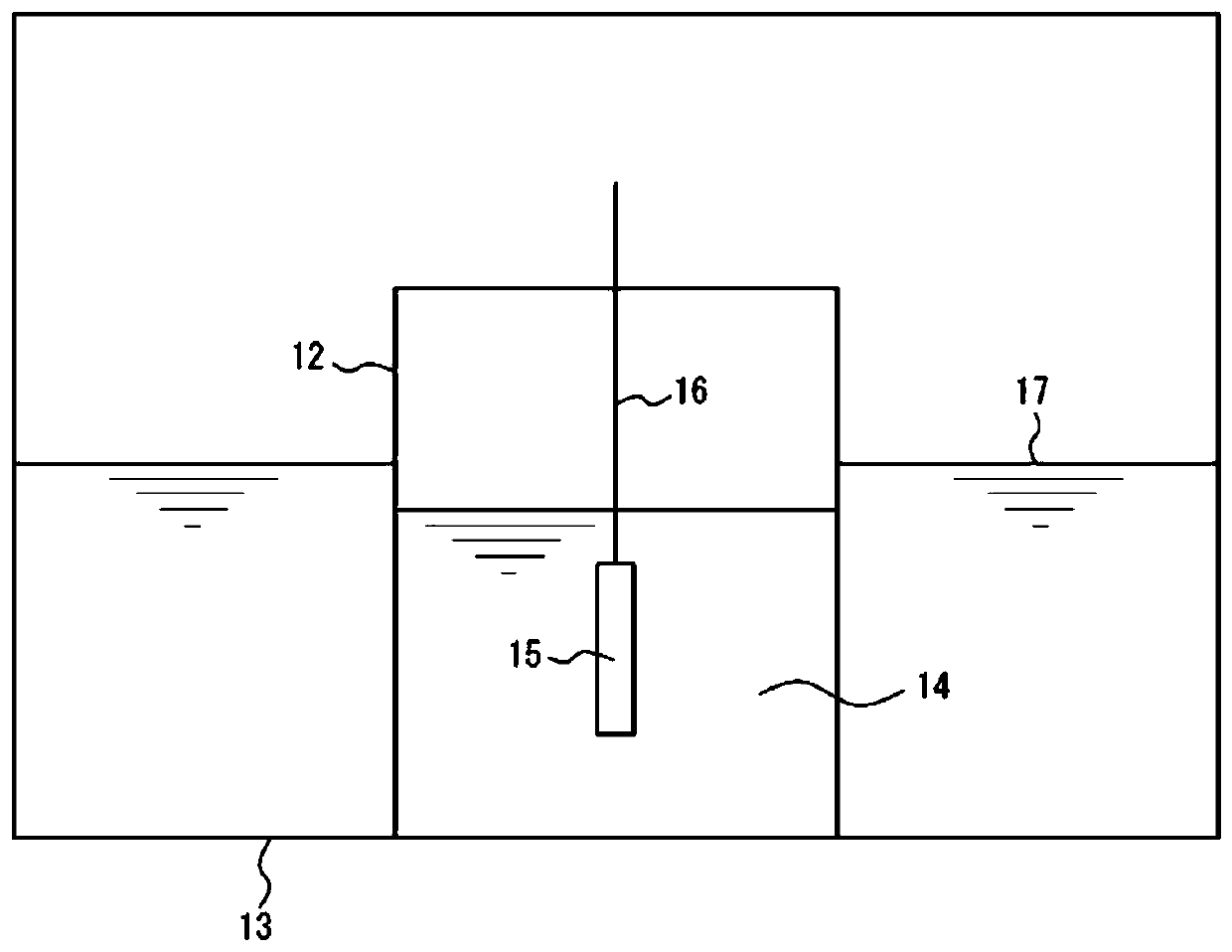

Image

Examples

Embodiment 1

[0135] Molten steel having the composition shown in Table 1 (the remainder being Fe and unavoidable impurities) was melted and continuously cast by a generally known method to produce a slab. After the slab was heated under the conditions shown in Table 2, it was hot-rolled under the conditions shown in Table 2 to make a hot-rolled steel sheet with a thickness of 40 mm, and was heated by water cooling under the conditions shown in Table 2. Cool to a cooling stop temperature of 450°C. It should be noted that in the heating atmosphere for heating the slab, oxygen is defined as the volume % described in Table 2, and gases other than oxygen are expressed as CO in volume %. 2 : 13%, CH 2 O: 14%, N 2 :margin.

[0136] Next, with respect to the obtained steel material, after removing the oxide film called the black scale on the surface, a test piece having the size described later was taken, and the measurement of the amount of solid solution Cu in the surface layer portion of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com