Nickel tungsten single-walled carbon nanotube composite plating solution, coating film and preparation method thereof

A technology of single-walled carbon nanotubes and composite plating solution, which is applied in the direction of electrolytic coatings and coatings, can solve the problems of large residual internal stress of the coating film, affecting the mechanical properties of the film layer, and local corrosion, so as to improve various performances and improve The effect of various properties and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

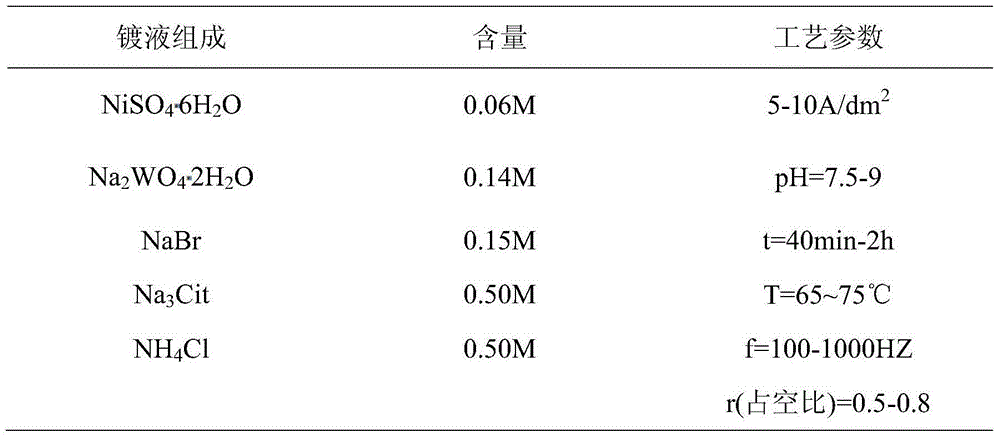

[0022] The nickel-tungsten single-walled carbon nanotube composite plating solution of the present invention consists of the following components:

[0023]

[0024] Utilize composite plating solution of the present invention to prepare the method for nickel-tungsten graphene oxide composite coating film as follows:

[0025] Utilize composite plating solution of the present invention to prepare the method for nickel-tungsten single-walled carbon nanotube composite coating film as follows:

[0026] First, the steel sheet is polished with sandpaper, then ultrasonically cleaned, degreased, ultrasonically cleaned again, then pickled and activated, then pulse electroplated, cleaned after electroplating, and the finished product is obtained after post-processing; process parameters in the process of pulse electroplating For: the current density is 0.1A / dm 2 , the pH value is 9, the time is 0.5h, the temperature is 80°C, the power is 500HZ, and the duty cycle is 1.0.

Embodiment 2

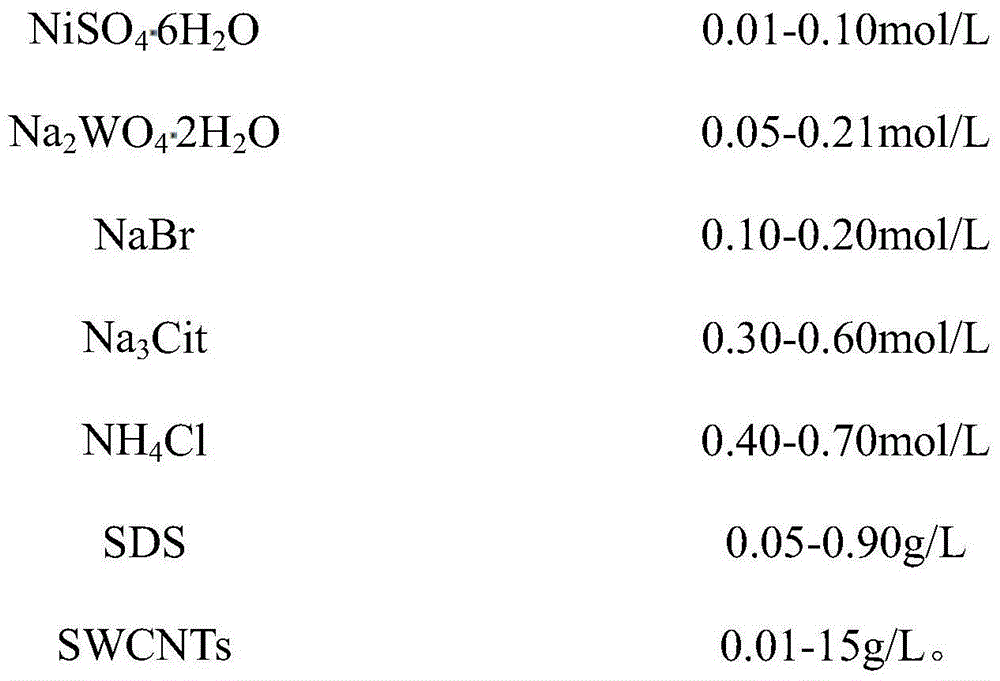

[0028] The nickel-tungsten single-walled carbon nanotube composite plating solution of the present invention consists of the following components:

[0029]

[0030] Utilize composite plating solution of the present invention to prepare the method for nickel-tungsten single-walled carbon nanotube composite coating film as follows:

[0031] First, the steel sheet is polished with sandpaper, then ultrasonically cleaned, degreased, ultrasonically cleaned again, then pickled and activated, then pulse electroplated, cleaned after electroplating, and the finished product is obtained after post-processing; process parameters in the process of pulse electroplating For: the current density is 10A / dm 2 , the pH value is 6, the time is 3h, the temperature is 50°C, the power is 1500HZ, and the duty cycle is 0.1.

Embodiment 3

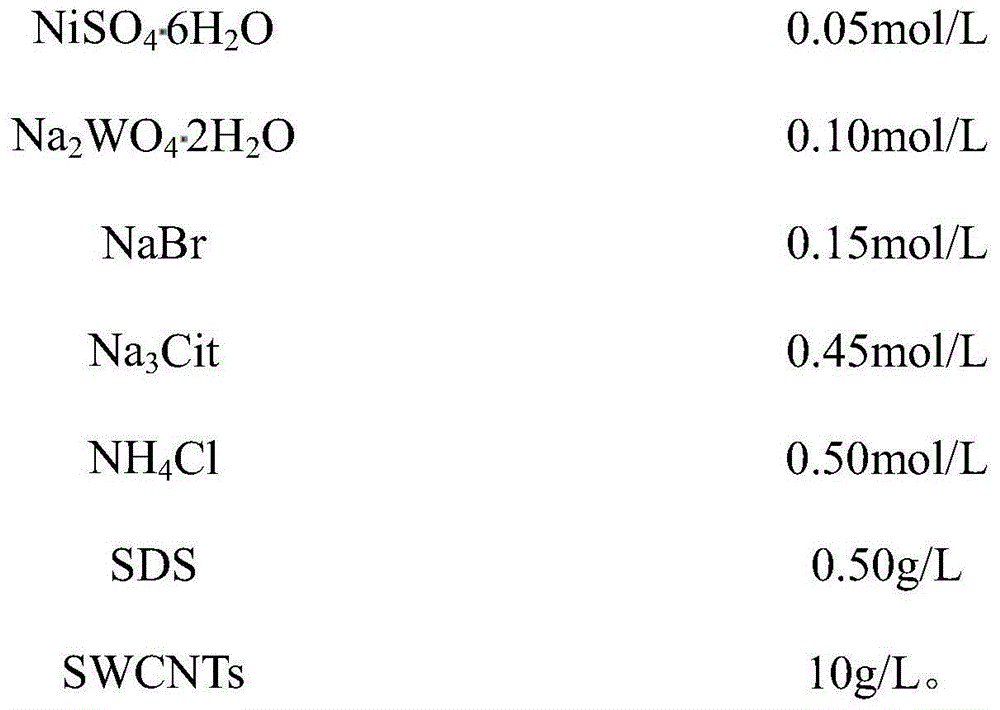

[0033] The nickel-tungsten single-walled carbon nanotube composite plating solution of the present invention consists of the following components:

[0034]

[0035] Utilize composite plating solution of the present invention to prepare the method for nickel-tungsten single-walled carbon nanotube composite coating film as follows:

[0036] First, the steel sheet is polished with sandpaper, then ultrasonically cleaned, degreased, ultrasonically cleaned again, then pickled and activated, then pulse electroplated, cleaned after electroplating, and the finished product is obtained after post-processing; process parameters in the process of pulse electroplating For: the current density is 5A / dm 2 , the pH value is 8, the time is 2h, the temperature is 70°C, the power is 1000HZ, and the duty cycle is 0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Self-corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com