A throwing and stirring concrete mixing robot

A technology of concrete and robots, applied in the direction of cement mixing equipment, clay preparation equipment, chemical instruments and methods, etc., to achieve the effect of increasing vertical height, efficient mixing efficiency, and improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

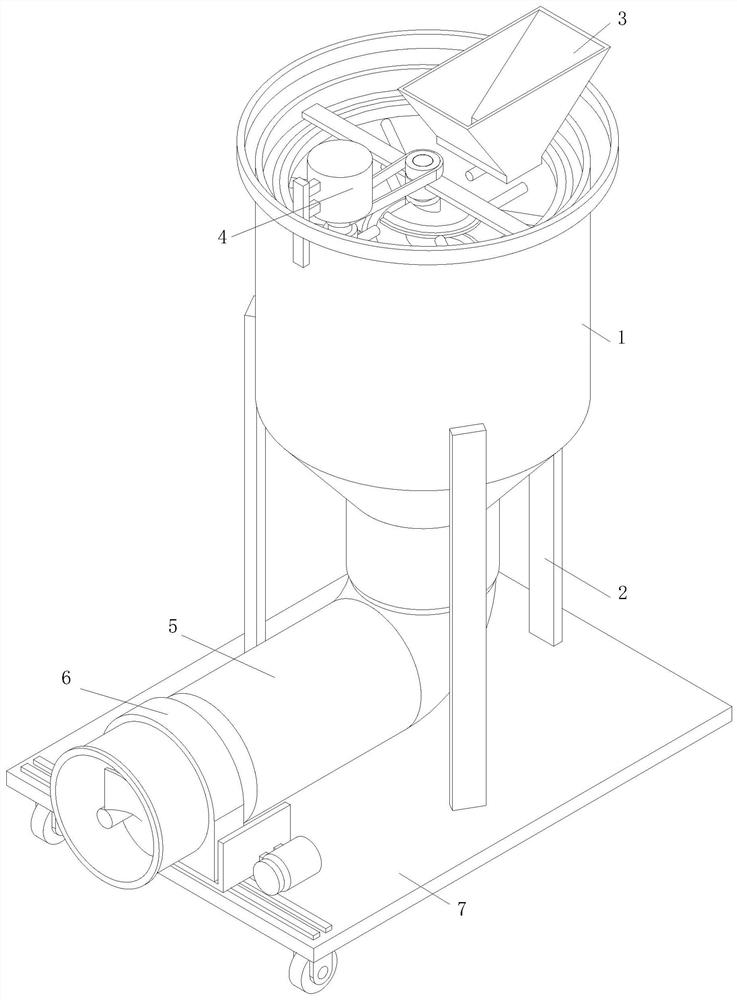

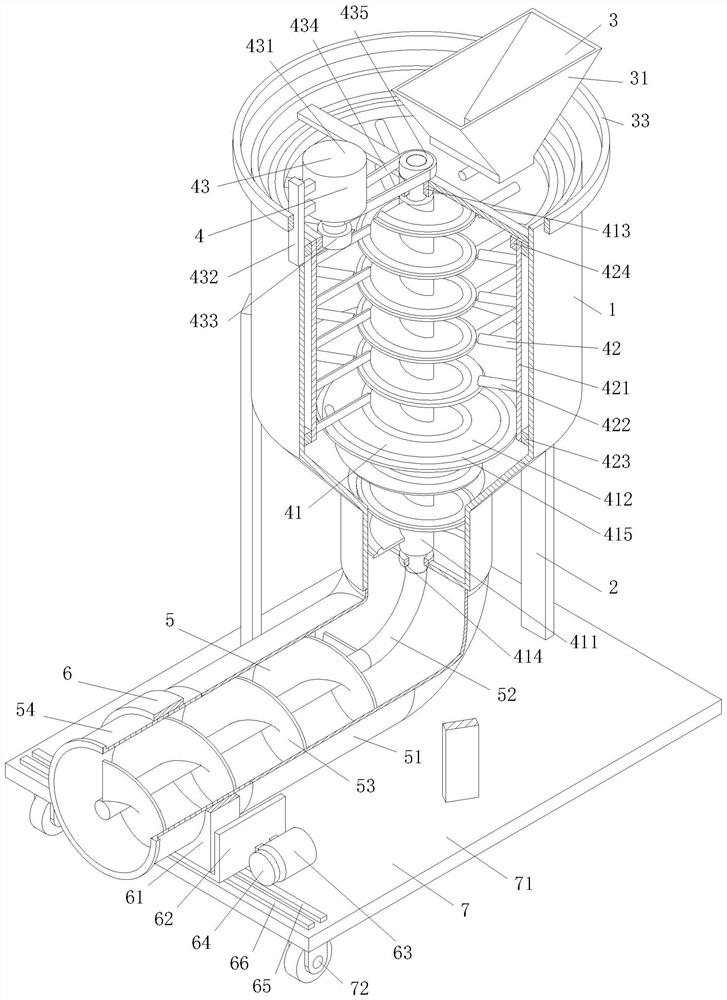

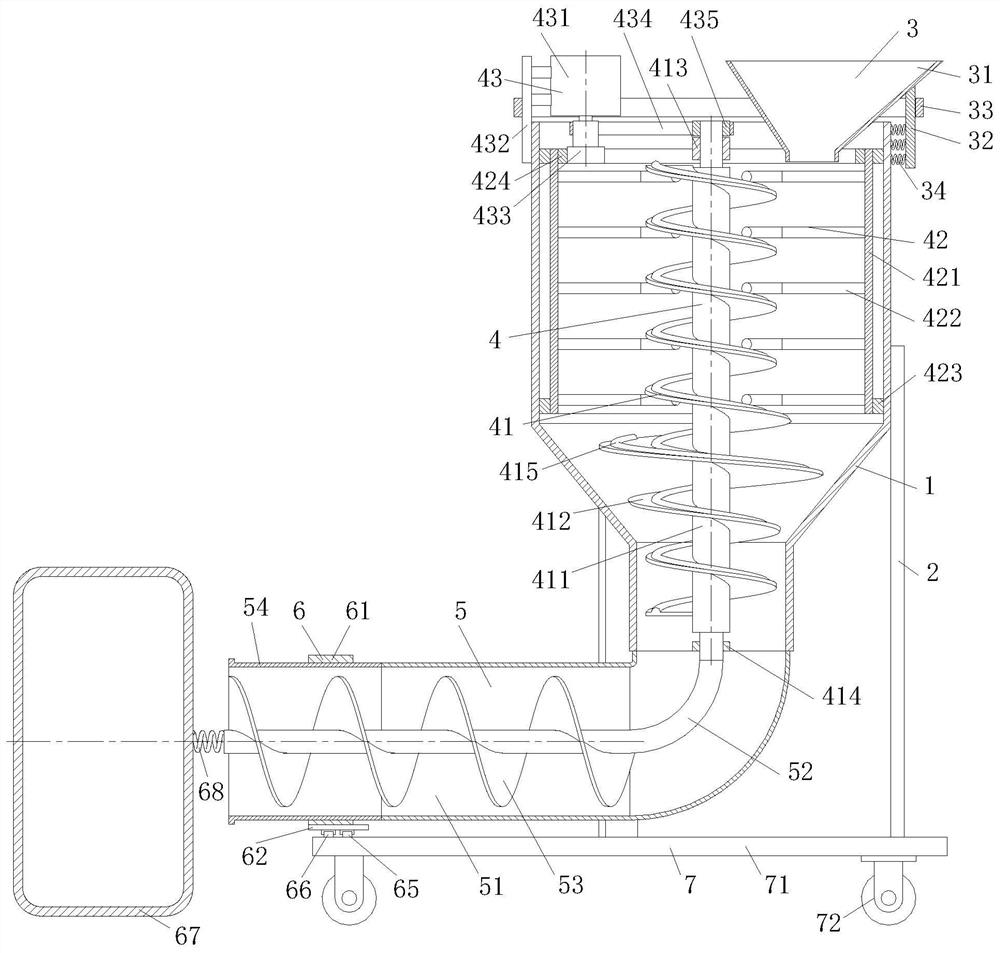

[0039] Such as Figure 1 to Figure 3 As shown, a throwing and mixing concrete mixing robot includes a tank body 1, a support column 2, a feeding part 3, a stirring part 4, a discharging part 5, a spreading part 6 and a walking part 7;

[0040] The tank body 1 is fixed above the running part 7 through the support column 2; the tank body 1 is arranged at one end of the running part 7;

[0041] The feeding part 3 is arranged above the tank body 1; the feeding part 3 is used to feed concrete raw materials into the tank body 1;

[0042] The stirring part 4 is arranged inside the tank body 1; the stirring part 4 includes a throwing element 41, a stirring element 42 and a driving element 43; throw upward; the stirring element 42 is used to stir the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com