Agitator for concrete production system

A production system and concrete technology, which is applied in the direction of cement mixing equipment, clay preparation equipment, chemical instruments and methods, etc., can solve the problems of low mixing efficiency and long time spent, and achieve good mixing effect, high mixing efficiency, and discharge thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

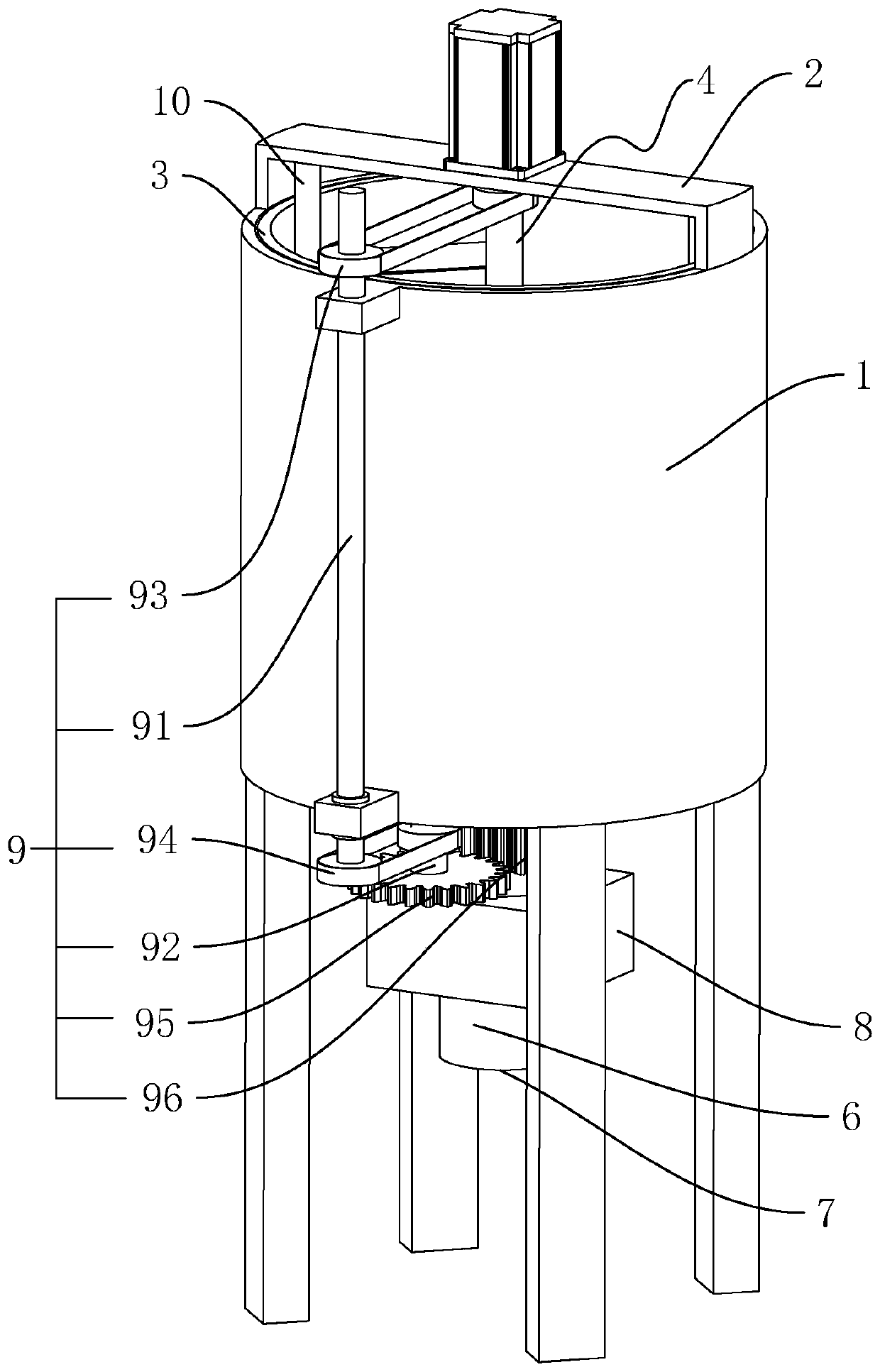

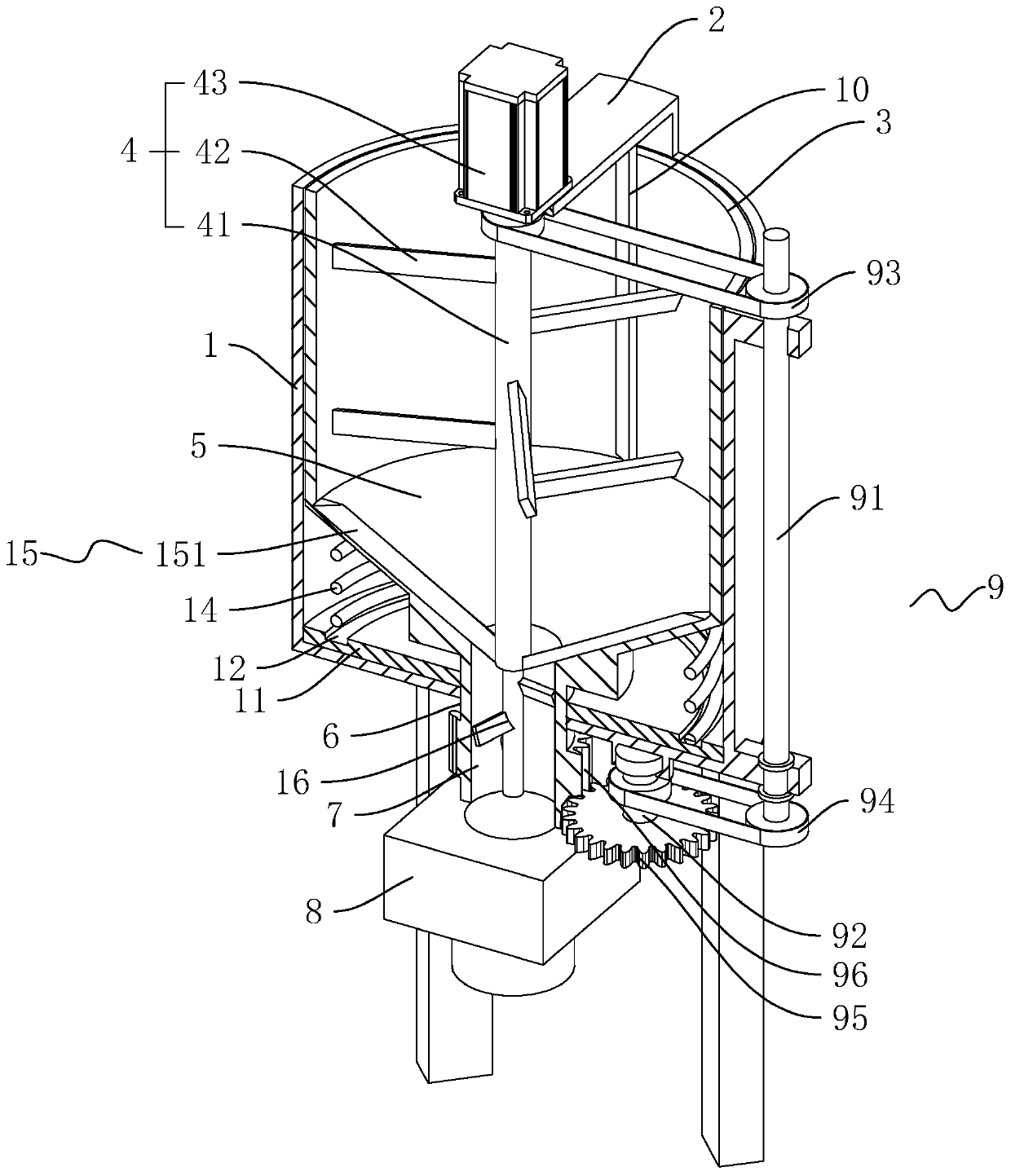

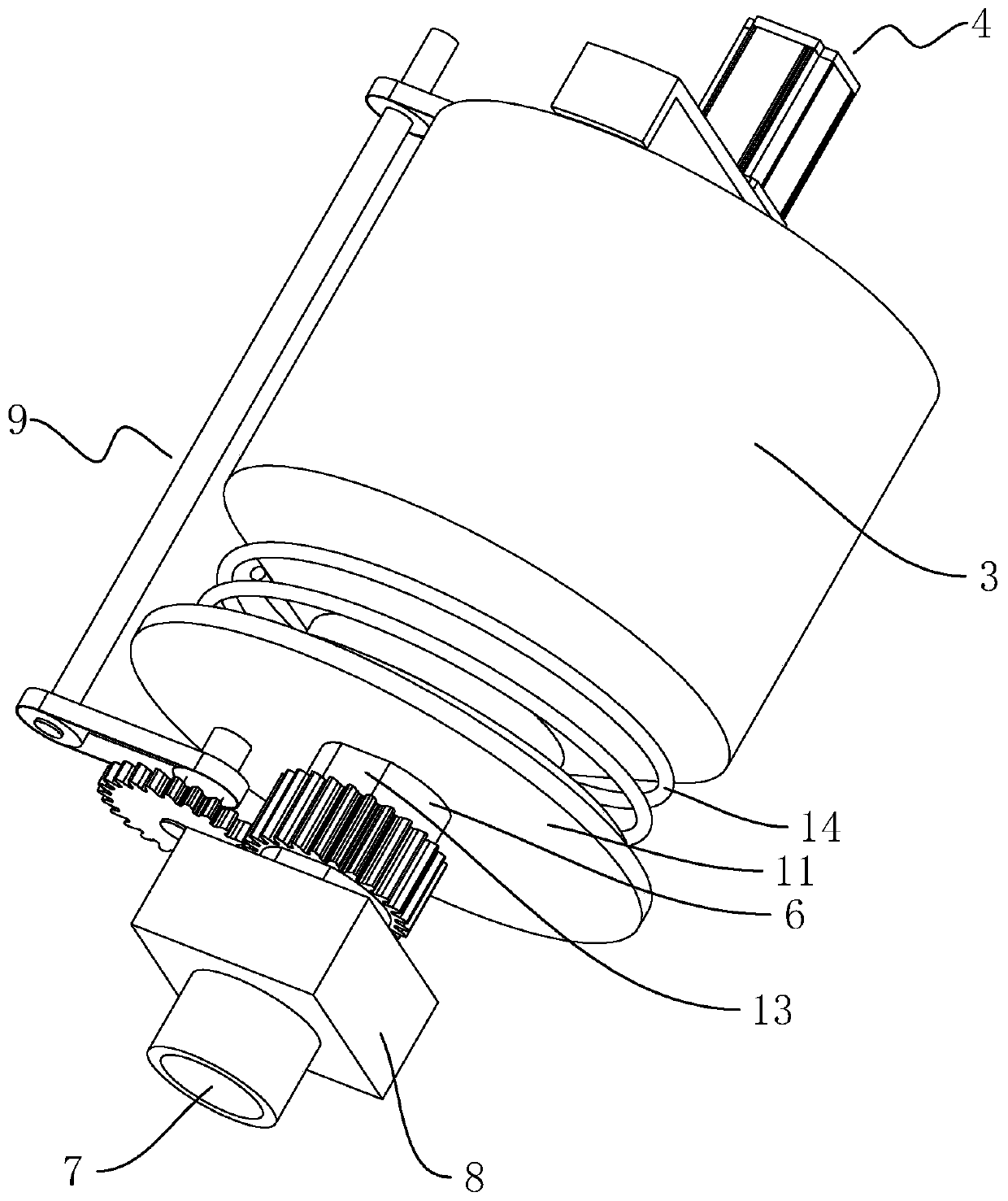

[0038] A mixer for a concrete production system, such as figure 1 , figure 2 As shown, it includes a barrel body 1 arranged vertically, the barrel body 1 is arranged in a cylindrical shape with the opening facing upwards, and the bottom of the barrel body 1 is set up by feet. A mounting frame 2 is fixed on the upper end of the barrel body 1, and the mounting frame 2 is erected on the barrel body 1 in a door shape. There is a mixing tank 3 rotating coaxially in the barrel body 1, and a stirring assembly 4 is also arranged on the mounting frame 2. The stirring assembly 4 includes a stirring rod 41 that is rotatably connected to the mounting frame 2 and penetrates into the mixing drum 3, and is fixed on the stirring rod 41. A number of stirring blades 42 on the outer wall and a driving motor 43 fixed on the mounting frame 2 . The stirring rod 41 is coaxially arranged with the stirring barrel 3, and several stirring blades 42 are arranged in a spiral along the axis of the stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com