Electric non-bearing vehicle body

A non-load-bearing, electric technology, applied in electric power units, power units, vehicle components, etc., can solve problems such as unfavorable lightweight design, reduced cruising range, and inapplicability to new energy vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

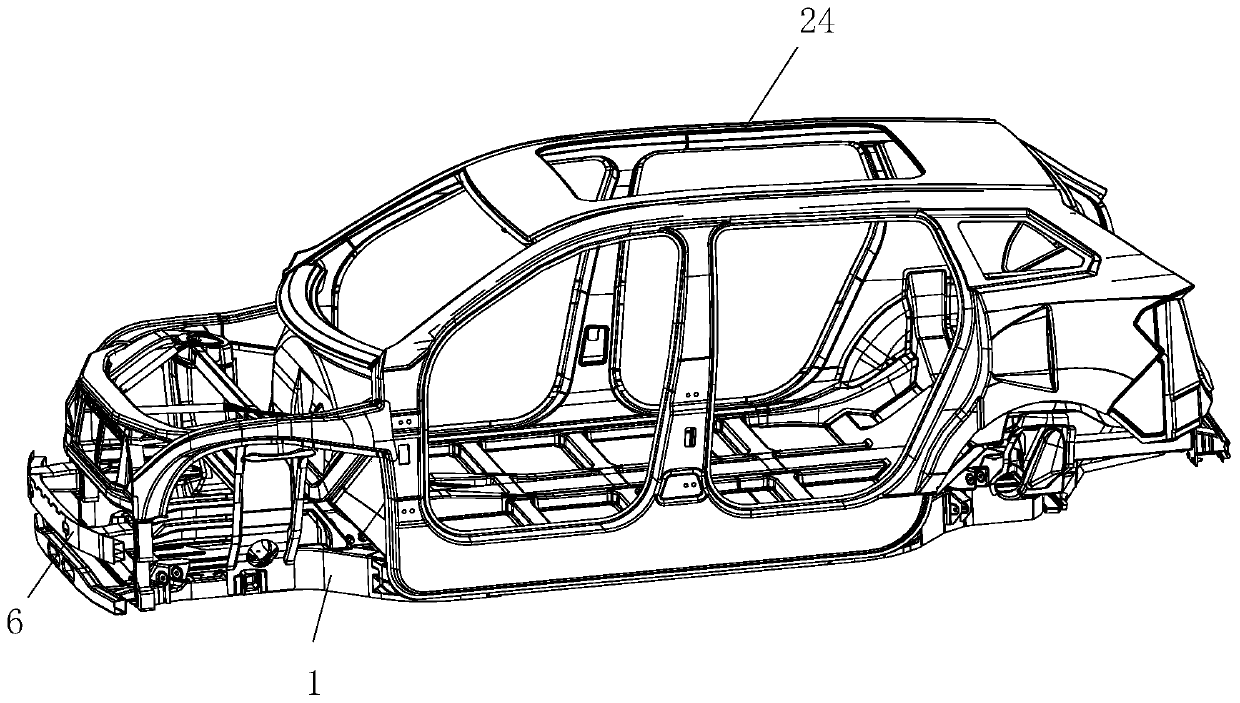

[0149] This embodiment relates to an electric non-load-bearing vehicle body, such as figure 1 As shown in , it includes a vehicle frame and a vehicle body 24 connected to the frame, wherein the vehicle frame specifically includes longitudinal beams 1 on both sides, and the front, middle, and The front structure, the middle structure and the rear structure are respectively arranged at the rear, and the vehicle body 24 includes a body of the vehicle body 24 composed of a front wall 2402 , a rear wall 2405 , a top cover 2404 , a floor 2406 and a B-pillar 2403 .

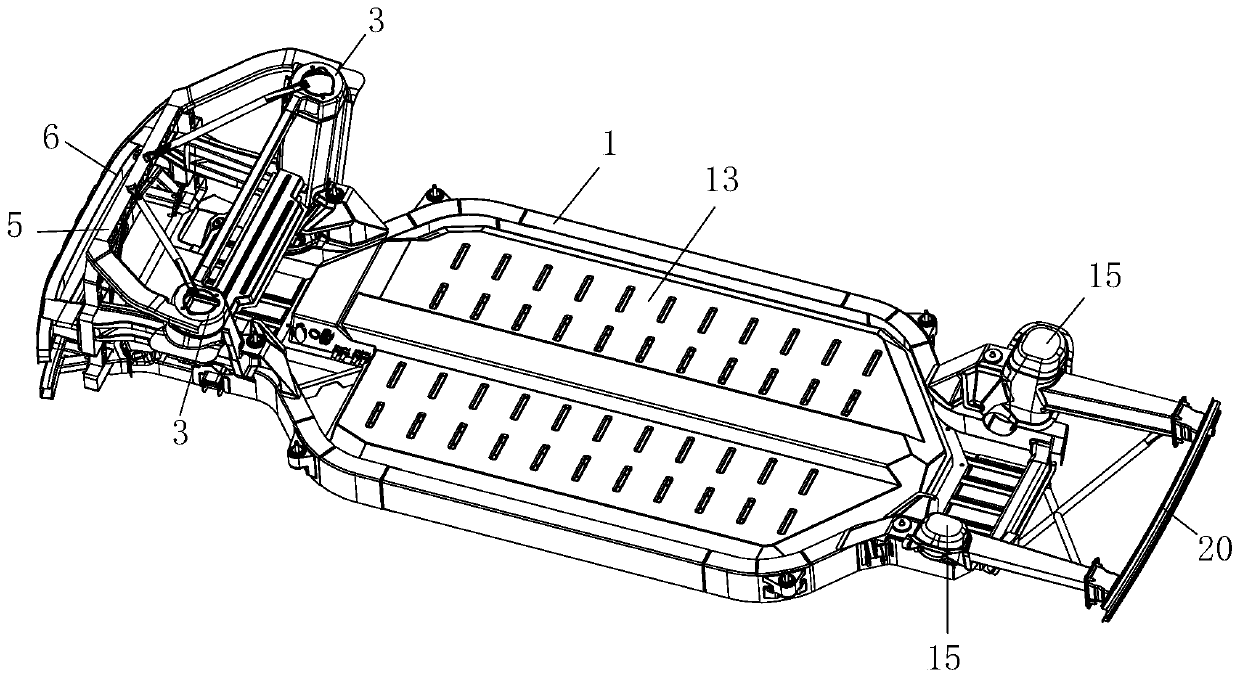

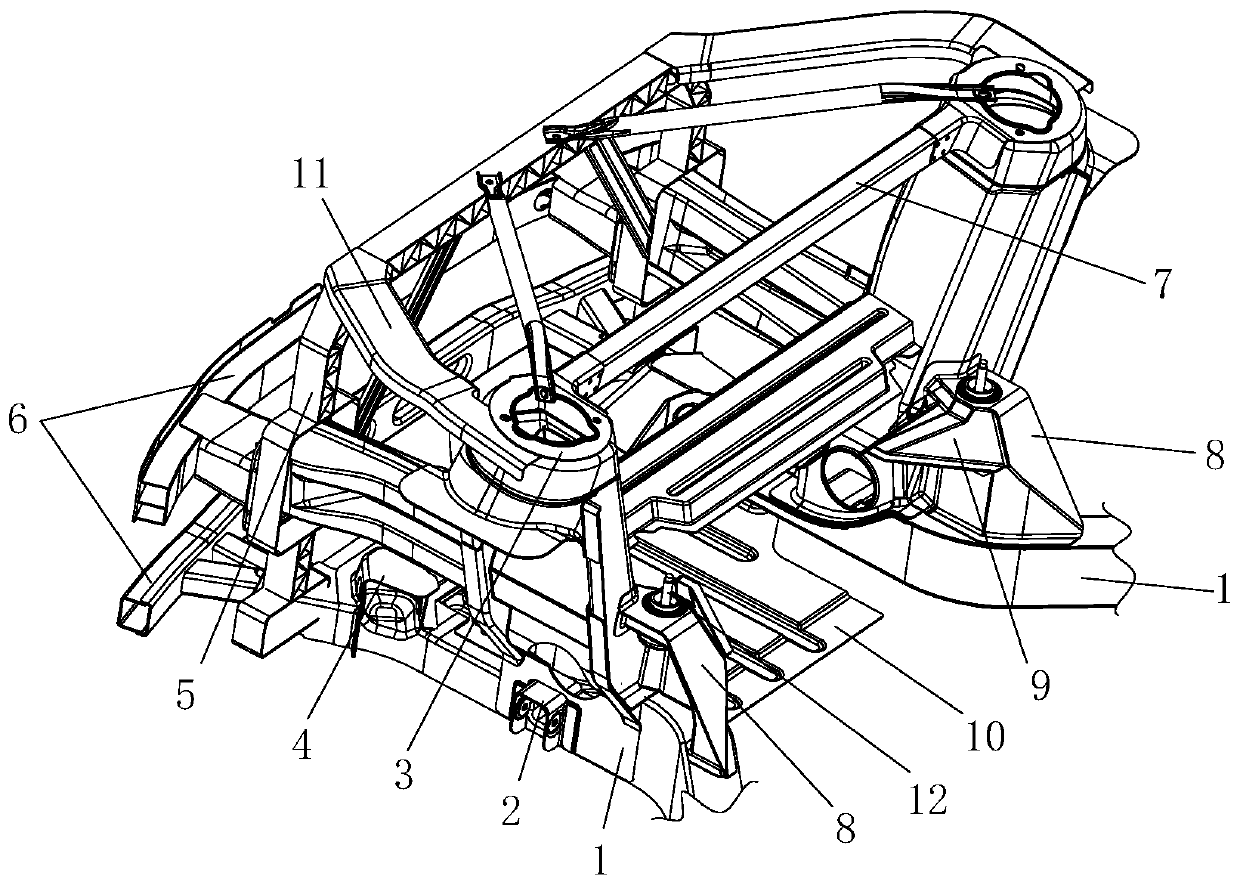

[0150] Specifically, the structure of the vehicle frame of this embodiment is as follows figure 2 As shown in , it includes longitudinal beams 1 on both sides, and the front, middle and rear structures respectively arranged at the front, middle and rear of the longitudinal beams 1 on both sides, and also includes A number of suspension installation brackets 8 are respectively arranged on the longitudinal beam 1 of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com