Roll material clip and stacker

A technology of coil materials and cargo clips, which is applied in the stacking of objects, conveyor objects, transportation and packaging, etc., can solve problems such as unstable center of gravity, and achieve the effect of improving reliability, low cost and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific embodiments.

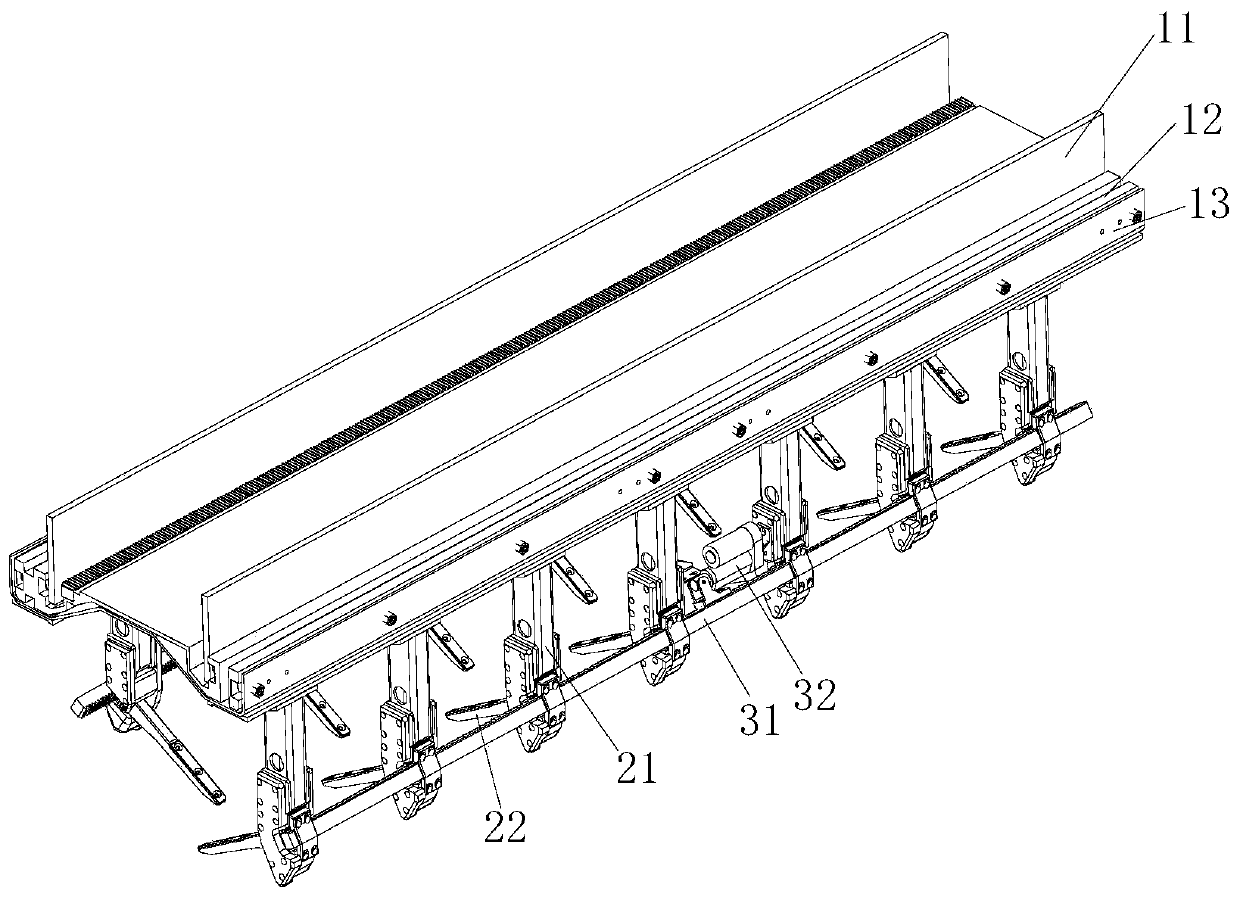

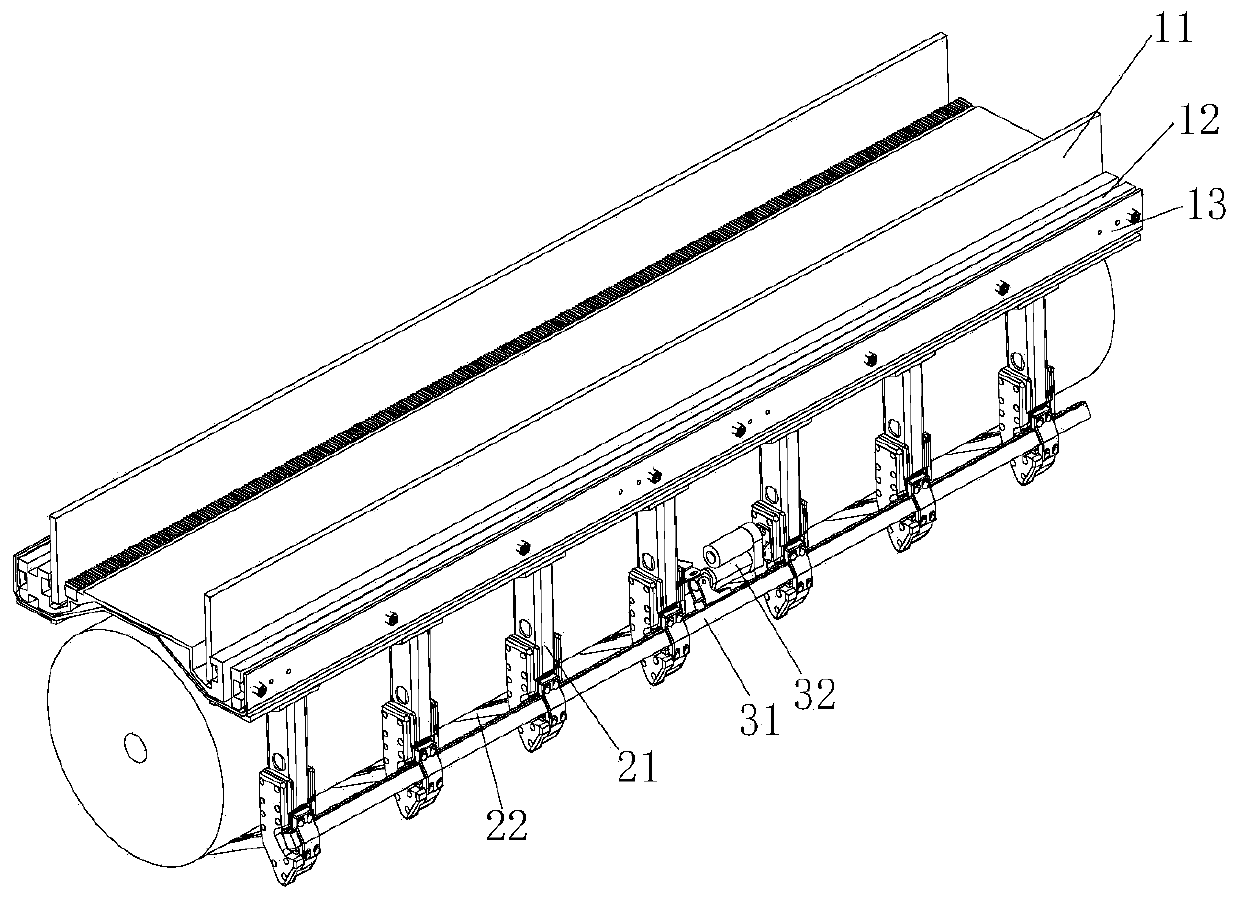

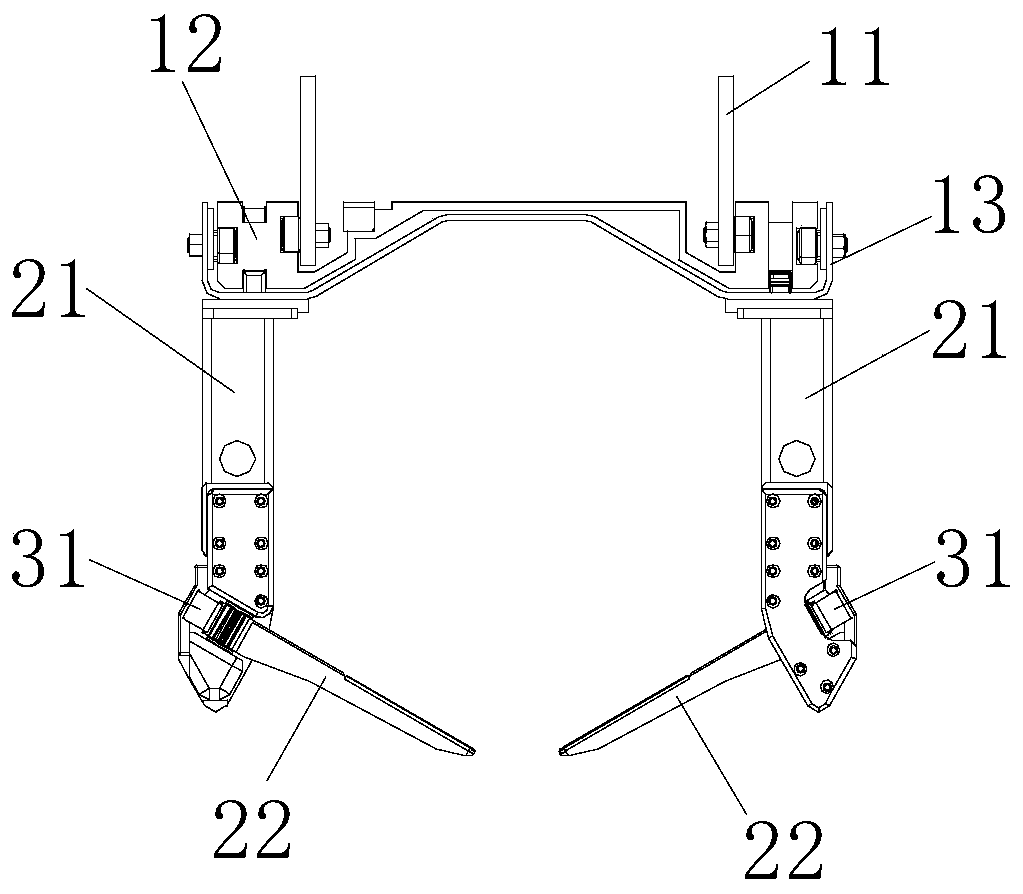

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 and Figure 8 As shown, the present invention includes a fork body, a cargo clip and a driving device; the fork body includes an upper fork 11 , a middle fork 12 and a lower fork 13 . The upper fork 11 is fixed on the pallet of the stacker, the middle fork 12 is located below the upper fork 11, and can move back and forth relative to the upper fork 11; the lower fork 13 is located below the middle fork 12, and the lower fork 13 can move relative to the middle fork 12 back and forth motion.

[0041] Such as Figure 5 and Figure 6 Shown (in this embodiment combined with Figure 5 and Figure 6 Some qualifiers used to describe the specific structure and mutual positional relationship of the upper fork 11, the middle fork 12 and the lower fork 13, such as the description of the upper surface, upwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com