Spinning-in device and spinning-in method of doffing trolley

A threading device and doffing technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of lower production efficiency, failure of yarn grabbing cylinders to grab, and increase of labor intensity of operators. Achieve reasonable structural design, improve work efficiency and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

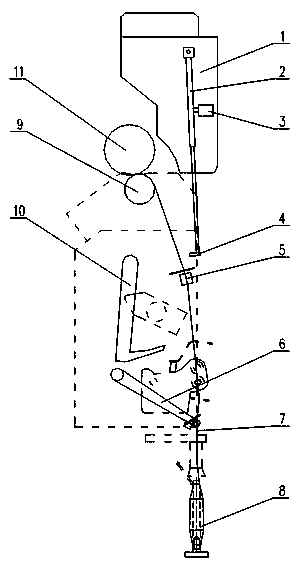

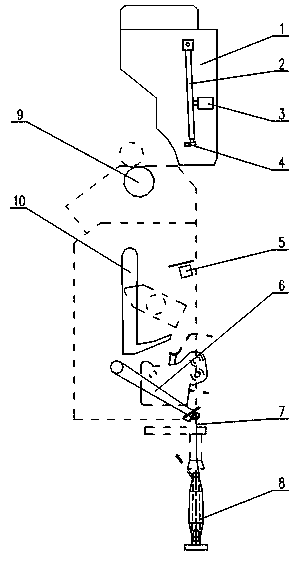

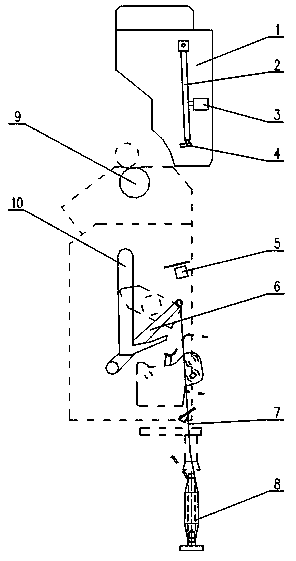

[0031] The present invention is described in further detail below in conjunction with accompanying drawing:

[0032] see Figure 1-Figure 5 , an embodiment of a spin-in device for a doffing trolley in the present invention, comprising a doffing trolley frame 1, a yarn grabbing mechanism, a groove drum 9, a yarn clearer 5, a small bobbin suction nozzle 6, and a large bobbin suction nozzle. The mouth 10 and the control system, the yarn grabbing mechanism includes a yarn grabbing cylinder 2, a yarn grabbing push cylinder 3 and a yarn grabbing scissors 4. The telescopic arm of the above-mentioned yarn-grabbing cylinder 2 is formed by plugging a section of telescopic tube and a section of telescopic rod. One end of the telescopic rod is provided with a yarn-grabbing scissors 4. The middle part of the pipe is connected, and the large suction nozzle 10 for the package is L-shaped, and the large suction nozzle 10 for the package participates in the doffing action.

[0033] Preferabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com