Treatment process of high-salt and high-organic waste liquid and waste liquid treatment equipment used

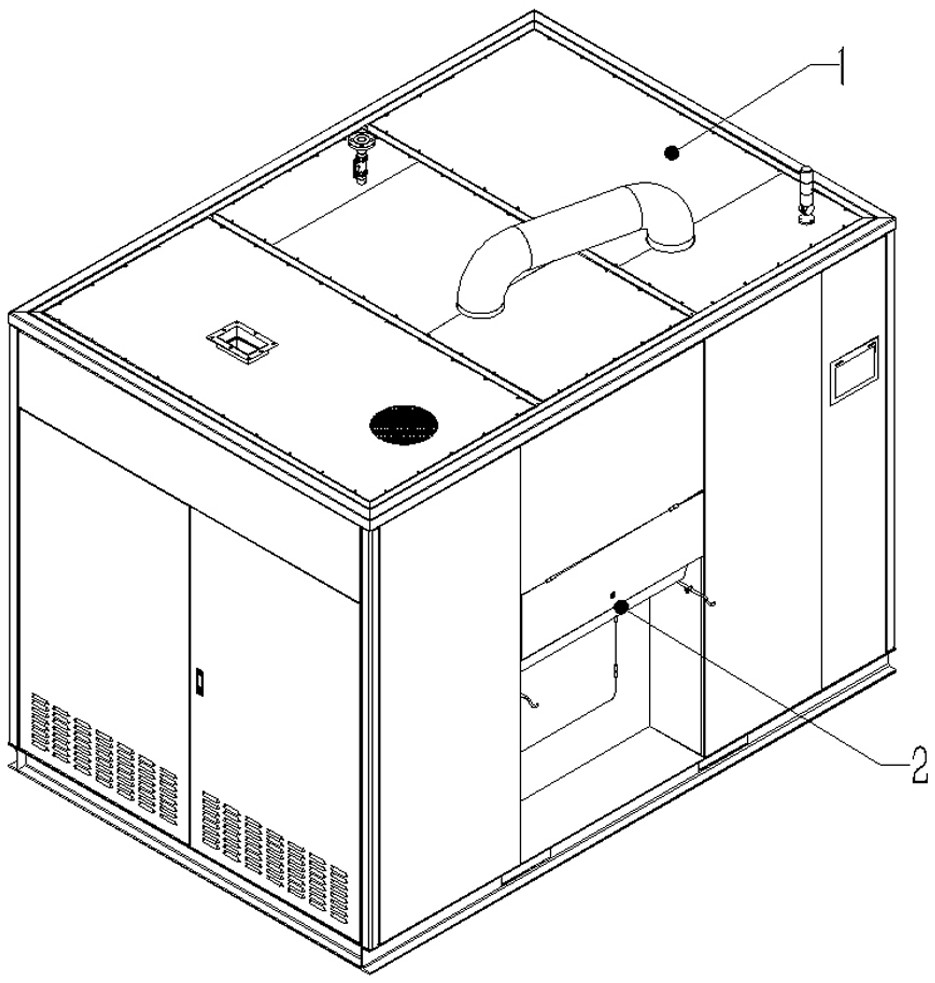

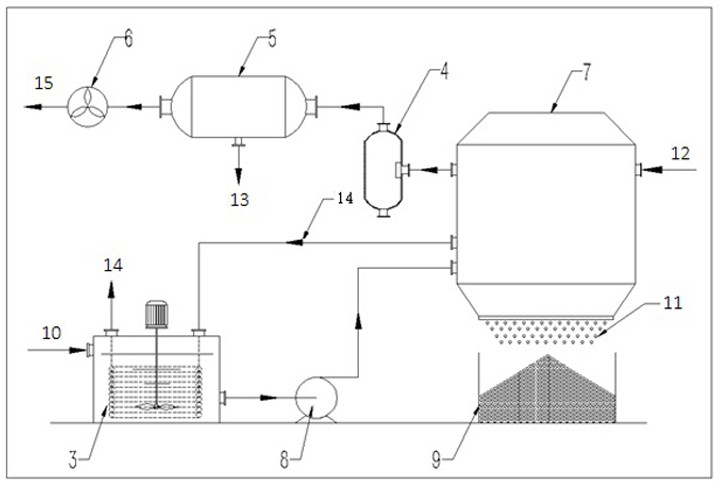

A treatment process and waste liquid treatment technology, applied in water/sewage treatment, multi-stage water/sewage treatment, heating water/sewage treatment, etc. Problems such as high moisture content, to achieve the effects of saving energy and water resources, efficient and stable heat transfer efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] The COD in waste liquid 10 produced by electroless nickel plating in a factory is 53900mg / L, and the solid content is 25.8%.

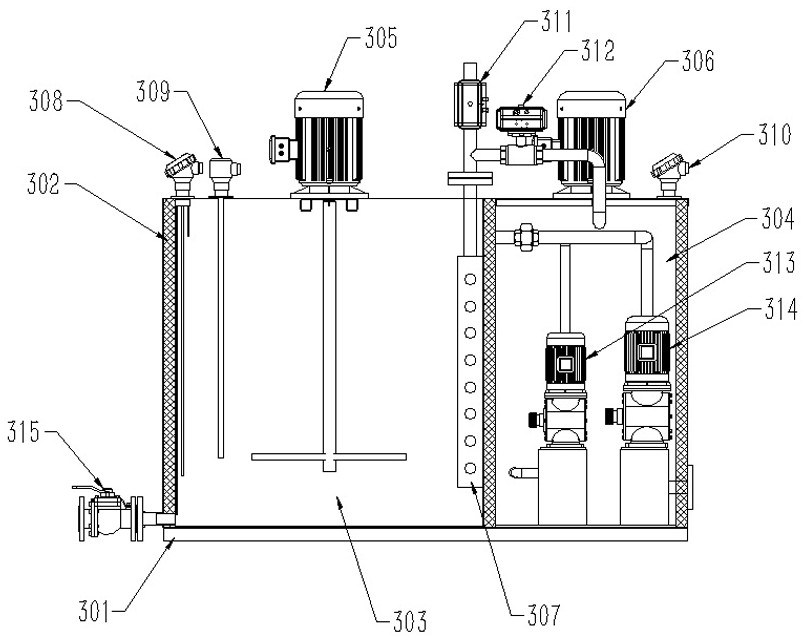

[0087] After the waste liquid 10 is preheated in the compounding tank 303, the temperature of the waste liquid 10 is higher than 70°C, and the compounding agent in the dispensing tank 304 is selected from a composition of sodium hydroxide, sodium sulfate and magnesium sulfate, wherein sodium hydroxide, sodium sulfate and The mass ratio of magnesium sulfate is 2:3:5. The preparation agent and steam condensate 14 are fully stirred and mixed to form a preparation agent. The dosage of the preparation agent is calculated according to the following formula:

[0088] Dosing amount of compounding agent=5.7*COD of waste liquid-original TDS of waste liquid;

[0089] Add the preparation agent to the preparation tank 303 according to the above-mentioned dosage, adjust the pH of the waste liquid 10 to 6, and the prepared waste liquid 10 is processed by the d...

Embodiment 2

[0091] The content of organic matter in the waste liquid 10 produced by a zinc-nickel alloy factory is 113800mg / L, and the solid content is 20.7%.

[0092] After the waste liquid 10 is preheated in the preparation tank 303, the temperature of the waste liquid 10 is higher than 80°C. The preparation agent in the dispensing tank 304 is a mixture of sodium silicate and magnesium sulfate with a mass ratio of 1:1. The preparation agent and steam The condensed water 14 is fully stirred and mixed to form a preparation agent, and the dosage of the preparation agent is calculated according to the following formula:

[0093] Dosing amount of preparation = 2.3* COD of waste liquid - TDS of waste liquid;

[0094] Add the preparation agent to the preparation tank 303 according to the above-mentioned dosage, adjust the pH of the waste liquid 10 to 14, and the prepared waste liquid 10 is processed by the drying integrated equipment 1 to obtain a strip-shaped solid material 11. The moisture c...

Embodiment 3

[0096] The COD in waste liquid 10 produced by nanofiltration of organophosphorus wastewater in a factory is 6320mg / L, the total phosphorus is 623mg / L, and the solid content is 7.2%.

[0097] After the waste liquid 10 is preheated in the preparation tank 303, the temperature of the waste liquid 10 is higher than 80°C. The preparation agent in the preparation tank 304 is ferrous sulfate, and the preparation agent is fully stirred and mixed with the steam condensate 14 to form a preparation agent. Dosage is calculated according to the following formula:

[0098] Dosing amount of preparation = 14* COD of waste liquid - TDS of waste liquid;

[0099] Add the preparation agent to the preparation tank 303 according to the above dosage, adjust the pH of the waste liquid 10 to 8, and the prepared waste liquid 10 is processed by the drying integrated equipment 1 to obtain a strip-shaped solid material 11. The moisture content of the solid material 11 is 9.0%, the melting temperature Tm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com