Construction method for monolithic track bed of track

A technology of integral ballast bed and construction method, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of delay in construction period, increase in cost, increase in track structure height, etc., and achieve the effect of large space positioning and reduction of needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

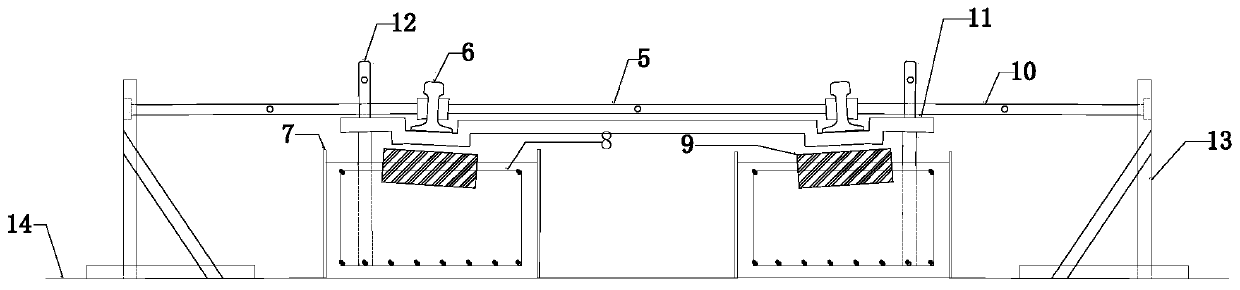

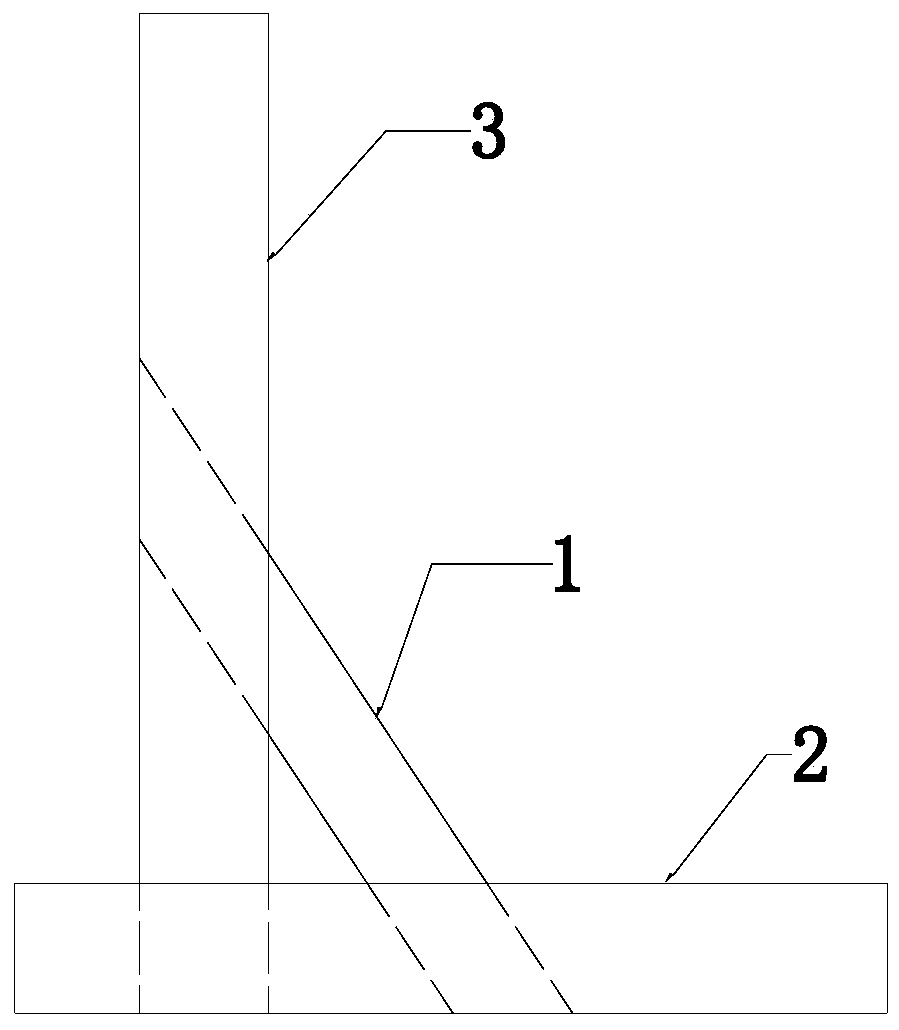

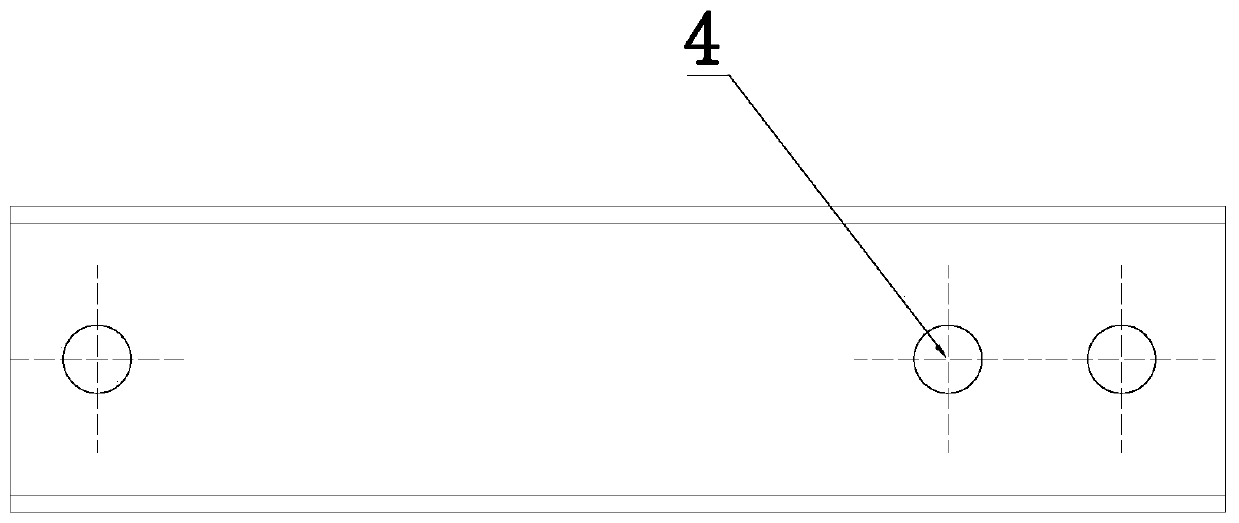

[0018] Embodiment 1 Take the elevated section as an example, the elevated section lacks the force points of diagonal braces. Therefore, when setting up the construction of the rail adjustment bracket, if figure 1 As shown, brace brackets are set on both sides of the rail row. Refer to the structure of the braced bracket figure 2 and image 3 , which includes: a bracket bottom plate, a vertical support and an oblique reinforcement plate. The bottom plate of the bracket is made of 12# national standard channel steel with a length of 350mm. There are multiple bolt holes at the bottom, and the bolt holes are distributed on the front and rear sides of the bottom plate of the bracket (corresponding to image 3 The right side and the left side in the middle), are respectively 25mm, 270mm and 330mm away from the rear end, and the diameter of the bolt hole is 16mm in the present embodiment. The vertical support adopts 10# national standard channel steel, and the vertical support a...

Embodiment 2

[0019] Embodiment 2 takes the bridge deck without concrete retaining wall as an example. Such as Figure 4 As shown, also set the diagonal brackets on both sides of the rail row. The structure of the brace bracket is the same as in Embodiment 1.

[0020] In Embodiment 1 and Embodiment 2, the rail adjustment brackets can all adopt the down-loading type rail adjustment brackets, and the rail adjustment brackets can be rationally distributed according to the quality of the steel rail and the support block per unit length and the bearing capacity of the support frame. Straight line 3m, curve 2.5m spacing layout, the layout of the support frame at the rail joint can be adjusted appropriately, the existing general section is used for rail adjustment support, the force point of the diagonal brace is set on the support bracket, and the overall ballast bed construction process is the same as that of the general section .

[0021] The diagonal brace bracket is fixed on the structural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com