Partition for fabricated building

A constructional, prefabricated technology, applied in the direction of buildings, building components, building structures, etc., can solve problems such as inconvenience in use and short length of partitions, and achieve the goal of improving thermal insulation performance, expanding the scope of use and market competitiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

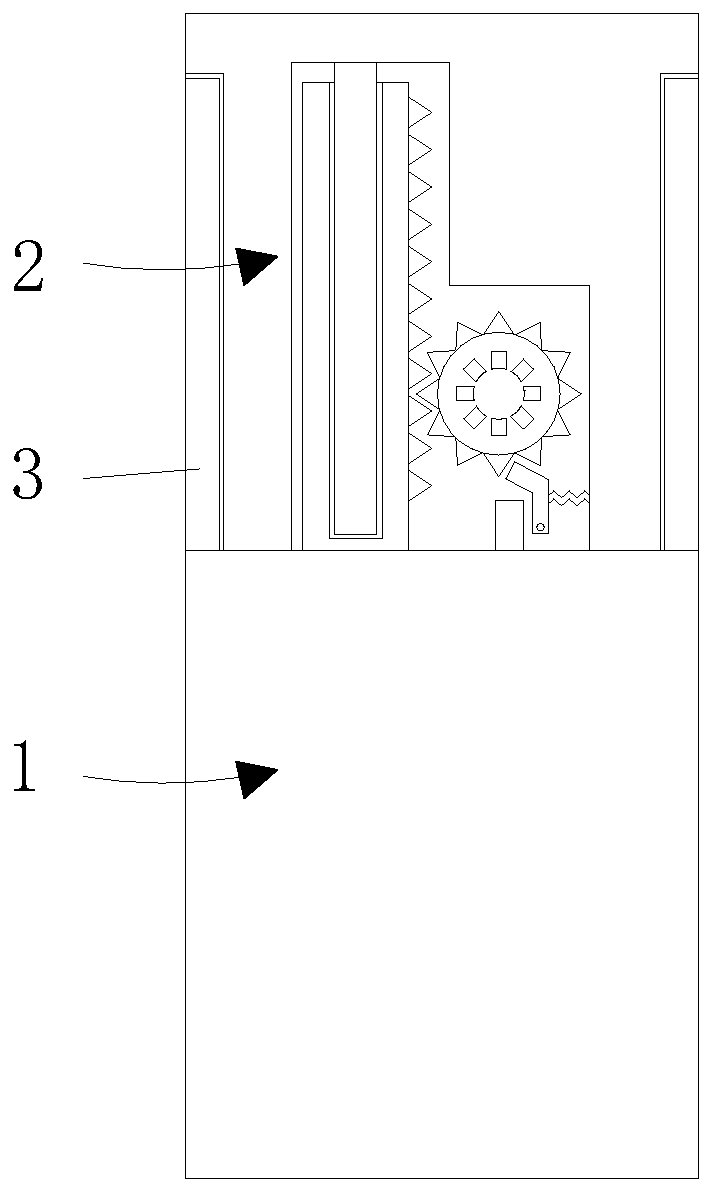

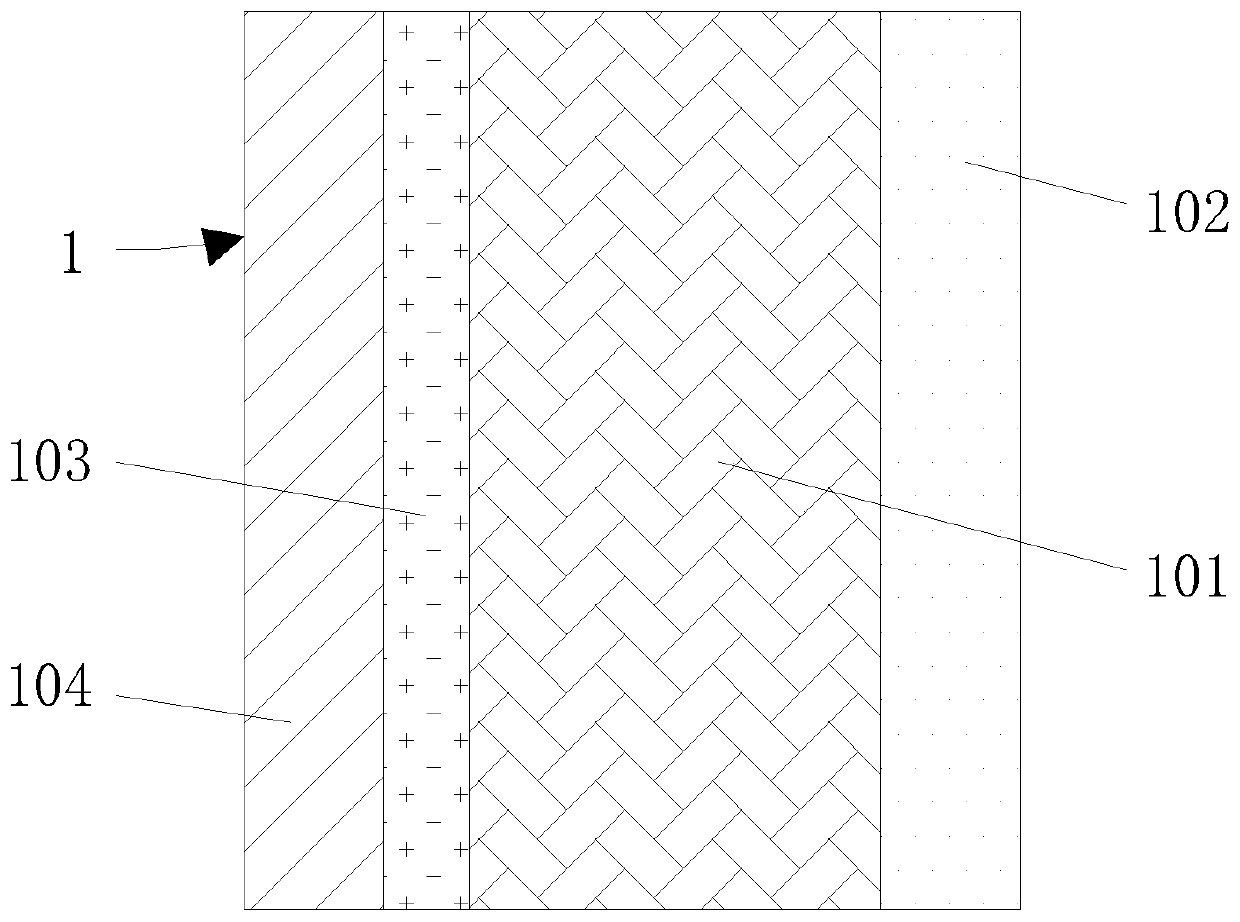

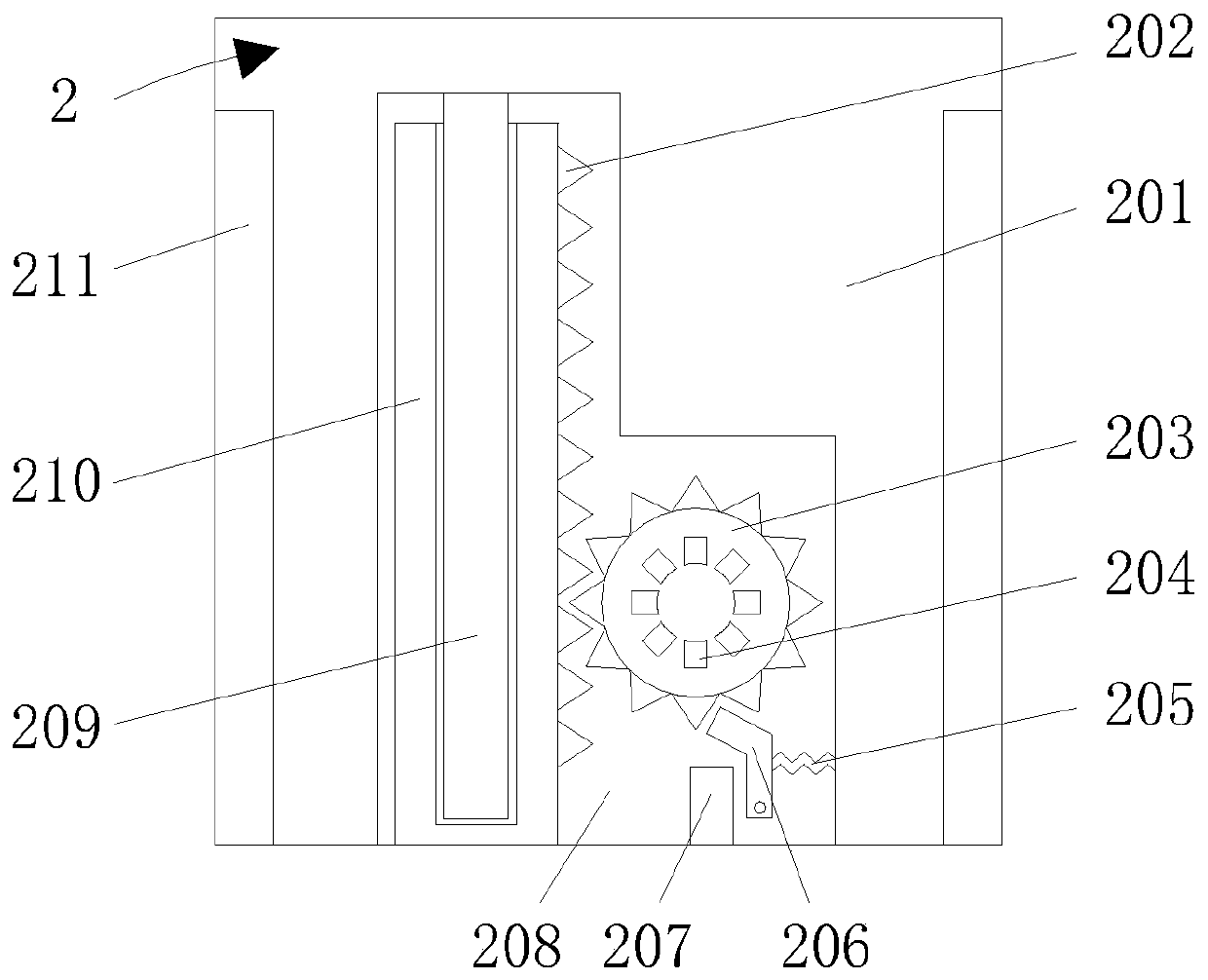

[0021] see Figure 1-5 , a prefabricated building partition, including a lower partition 1, an upper partition 2 and an adjustment mechanism 4, people can insert the anchor rod 404 into the adjustment hole 204 according to the needs and then turn the handle 401, and the anchor rod 404 can drive and adjust When the roller 203 rotates, the adjusting roller 203 will mesh with the teeth 202 to drive the adjusting rod 210 to move. When the upper partition 2 moves to the required position, stop rotating the rocker 401 and move the anchor rod 404 from the adjusting hole 204 Just pull it out, so that the partition has the function of adjusting the height, which brings great convenience to people's use. The lower partition 1 includes the lower base plate 101, the rock wool board 102, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com