Machining path intelligent adjusting and measuring structure and measuring method

A technology of intelligent adjustment and processing path, applied in metal processing equipment, manufacturing tools, control of workpiece feed movement, etc., can solve the problem that inner and outer circles cannot be automatically measured and compensated for cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

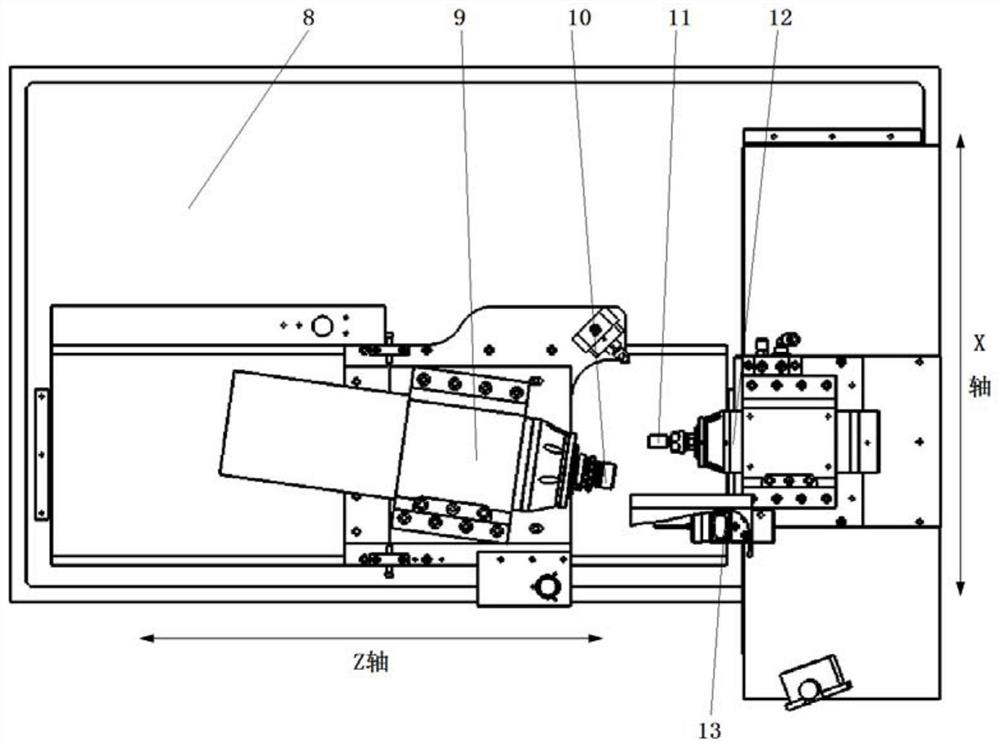

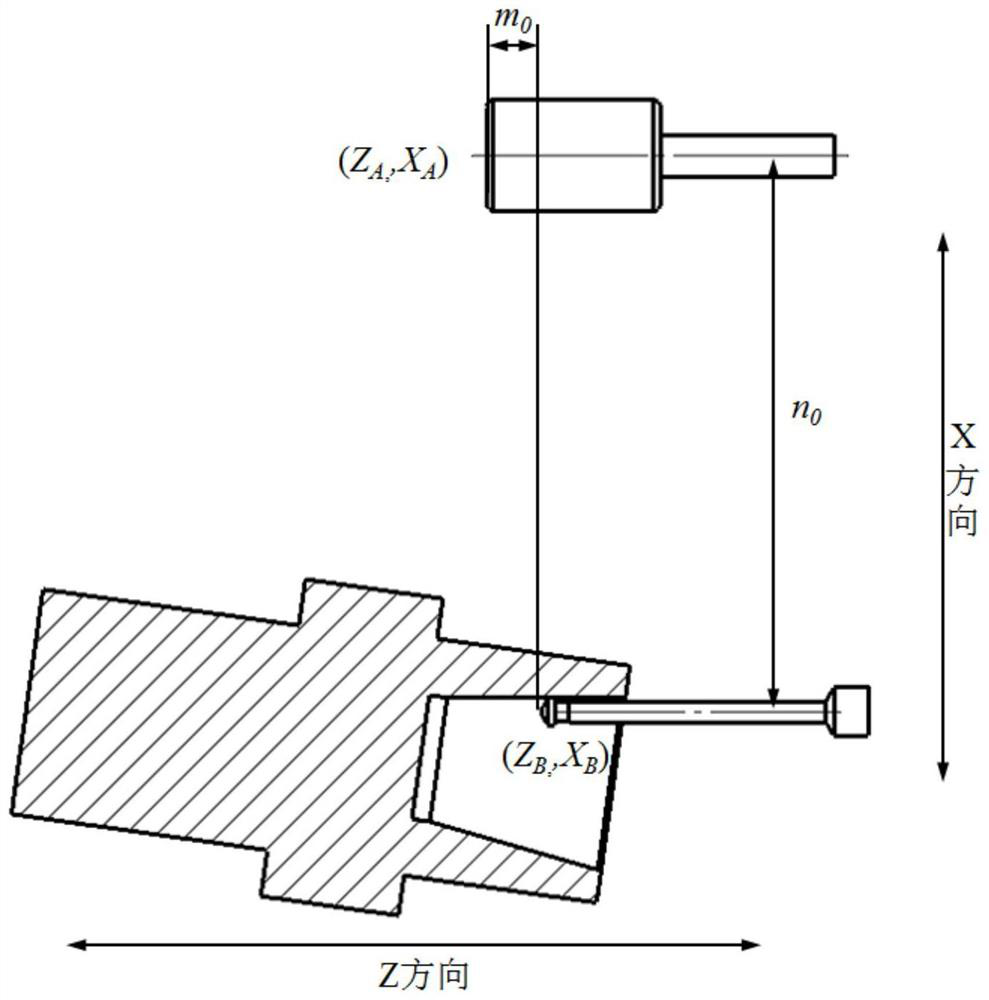

[0035] Comply with the above technical solutions, such as Figure 1 to Figure 3 As shown, this embodiment provides an intelligent compensation structure and method for processing paths, which can automatically detect and compensate the machining allowance of the workpiece during the internal and external cylindrical grinding process.

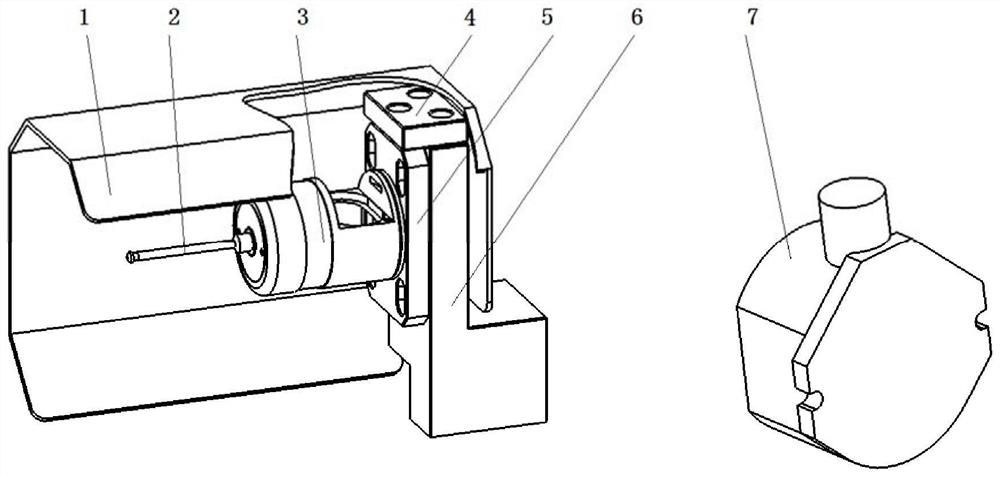

[0036] An intelligent measurement structure of a processing path according to the present invention includes an installation adjustment part, a protective cover 1 and a receiver 7;

[0037] The installation and adjustment part mainly includes the stylus 2 , the probe 3 , the probe mounting plate 5 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com