Stand column pouring template

A column and formwork technology, which is applied in the field of column pouring formwork, can solve problems such as waste of steel, and achieve the effects of saving steel, improving pouring efficiency, and saving construction sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

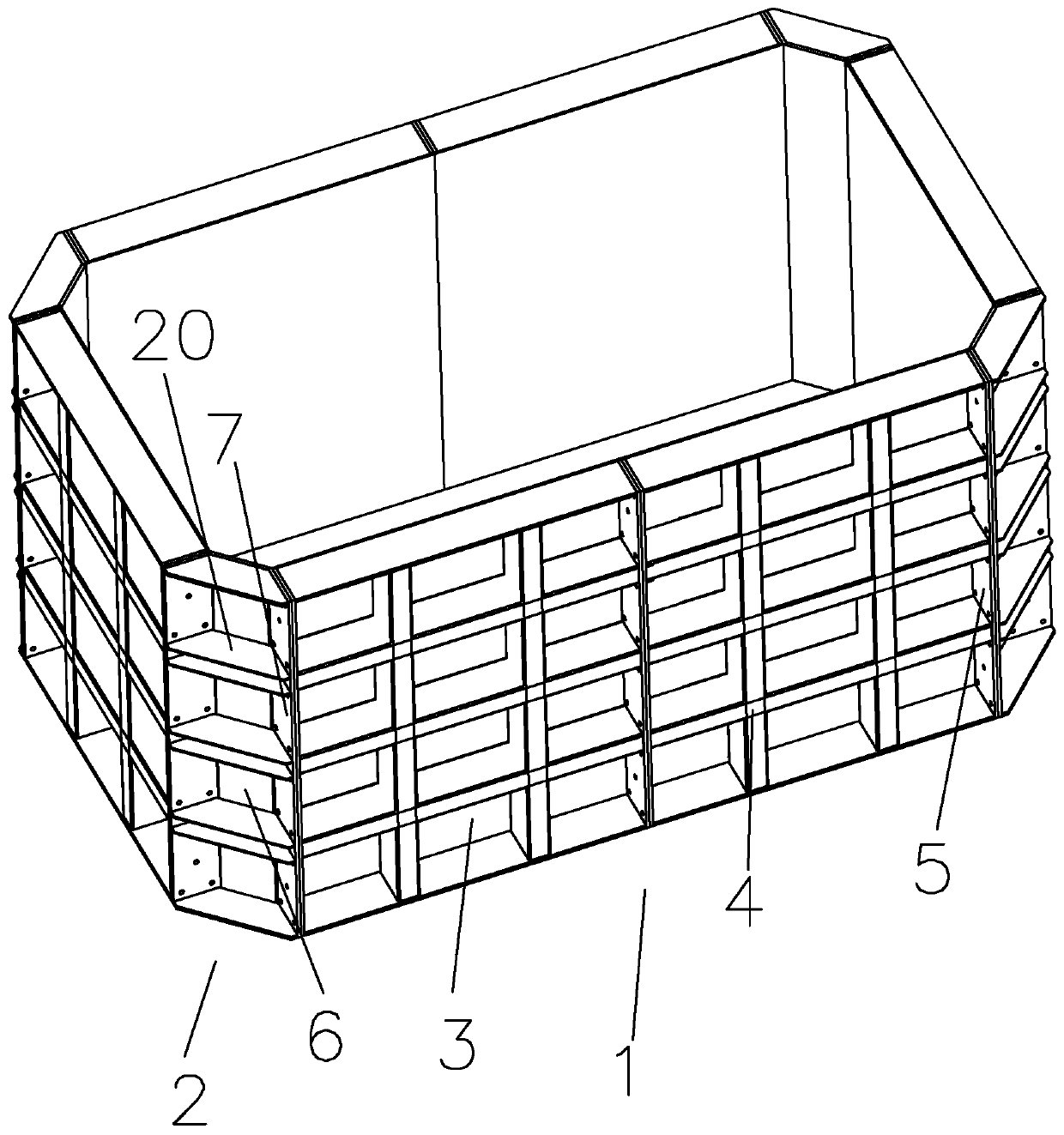

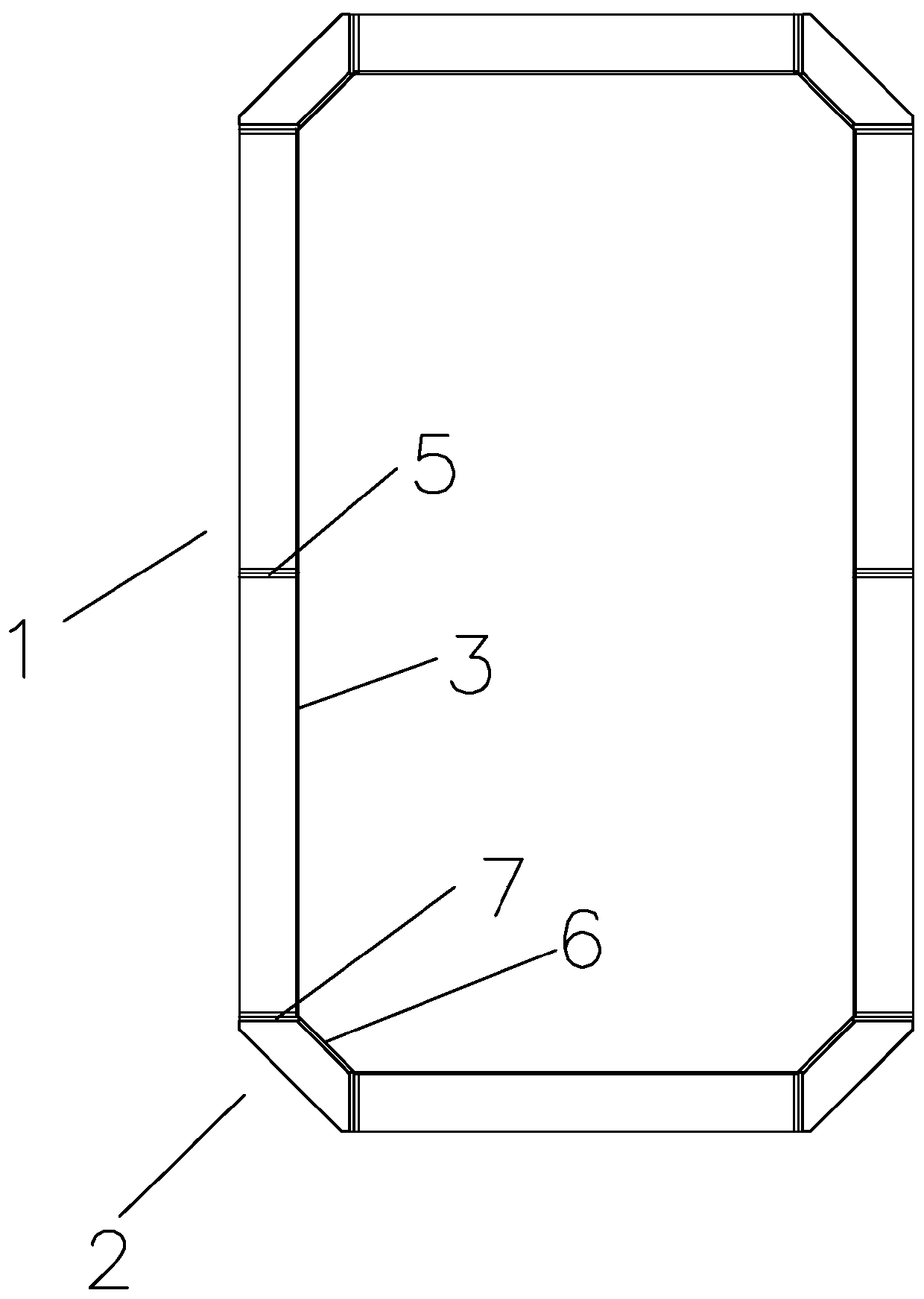

[0023] see Figure 1 to Figure 2 ,

[0024] A formwork for pouring a column, including several side plate parts 1 for pouring the side of the column, and several corner parts 2 for pouring the corners of the column. The side plate parts 1 and the corner parts 2 are arranged at intervals to form a column structure. The side panel 1 is detachably connected to its adjacent corner part 2; the corner part 2 is located at the edge of the corresponding side panel 1, and the side panel 1 includes at least one side panel module, and the side panel module includes pouring Side plate 3, a connecting plate 5 positioned at the edge of the pouring side plate 3, the corner part 2 includes a corner pouring side plate 6, a second connecting plate 7 positioned at the edge of the corner pouring side plate 6, the corner pouring side plate 6 is Planar or arc-shaped; the connecting plate 5 on the side of the side plate 1 adjacent to the corner part 2 and the corresponding second connecting plate 7...

Embodiment

[0025] Embodiment principle:

[0026] It should be noted that the inner side mentioned in this article refers to the side facing the inside of the formwork.

[0027] When pouring, the side plate 1 is a flat plate structure, which is used to pour the side of the column, and the corner part 2 is used to pour the chamfer of the column. When it is necessary to pour columns of different sizes, just replace the side plate with a different width That is, since the side plate part is composed of at least one side plate formwork, assuming that the width of the side plate formwork is 500, when a side plate part with a width of 1000 is required, the two side plate formworks can be connected by bolts. By analogy, when the side panels are assembled, the side panel modules are spliced together in turn, and the connecting panels are connected by bolts; for columns of different heights, in the same way, multiple side panels (corner parts) are stacked up and down to meet the requirements. C...

Embodiment 2

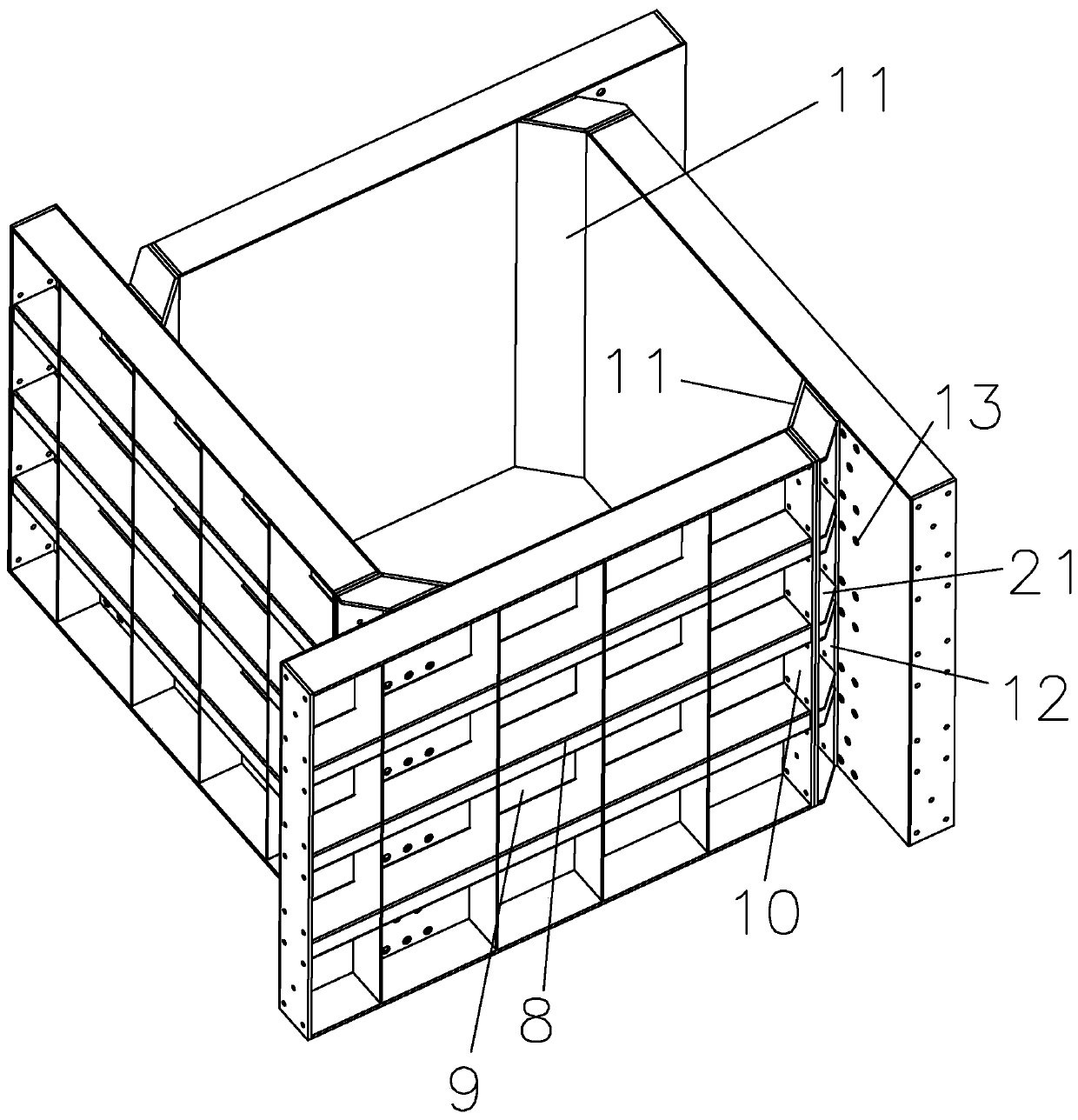

[0029] see Figure 3 to Figure 4 , a formwork for pouring a column, comprising several side plate parts 1 for pouring the sides of the column, several corner parts 2 for pouring the corners of the column, the side plate parts 1 and the corner parts 2 are arranged at intervals to form a column structure, The side panel 1 is detachably connected to its adjacent corner part 2; the side panel 1 includes a second casting side panel 9, a third connecting panel 10 located at the edge of the second casting side panel 9, and the corner part 2 includes a second corner casting side plate 11, a fourth connecting plate 12 located at the edge of the second corner casting side plate 11, the second corner casting side plate 11 is planar or arc-shaped, and the second One side of the corner pouring side plate 11 abuts against the edge of the second pouring side plate 9 on the corresponding side, and the other side of the second corner pouring side plate 11 abuts against the inner side of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com