Active anti-sticking PDC drill bit with rotary rock breaking device

A technology of rotary rock breaking and drill bit, which is applied in the direction of drill bit, earthwork drilling, drilling equipment, etc., which can solve the problems of lower drilling efficiency, increased friction between the drill bit and the well wall, and increased drilling cost, so as to reduce the risk of drill sticking at the bottom of the well, Improve chip removal ability and save design space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

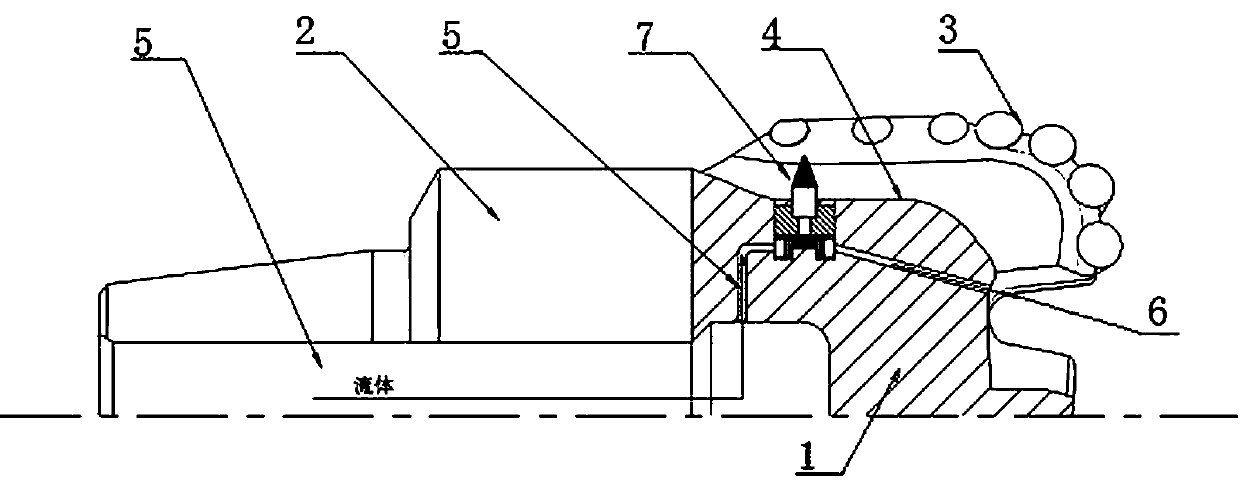

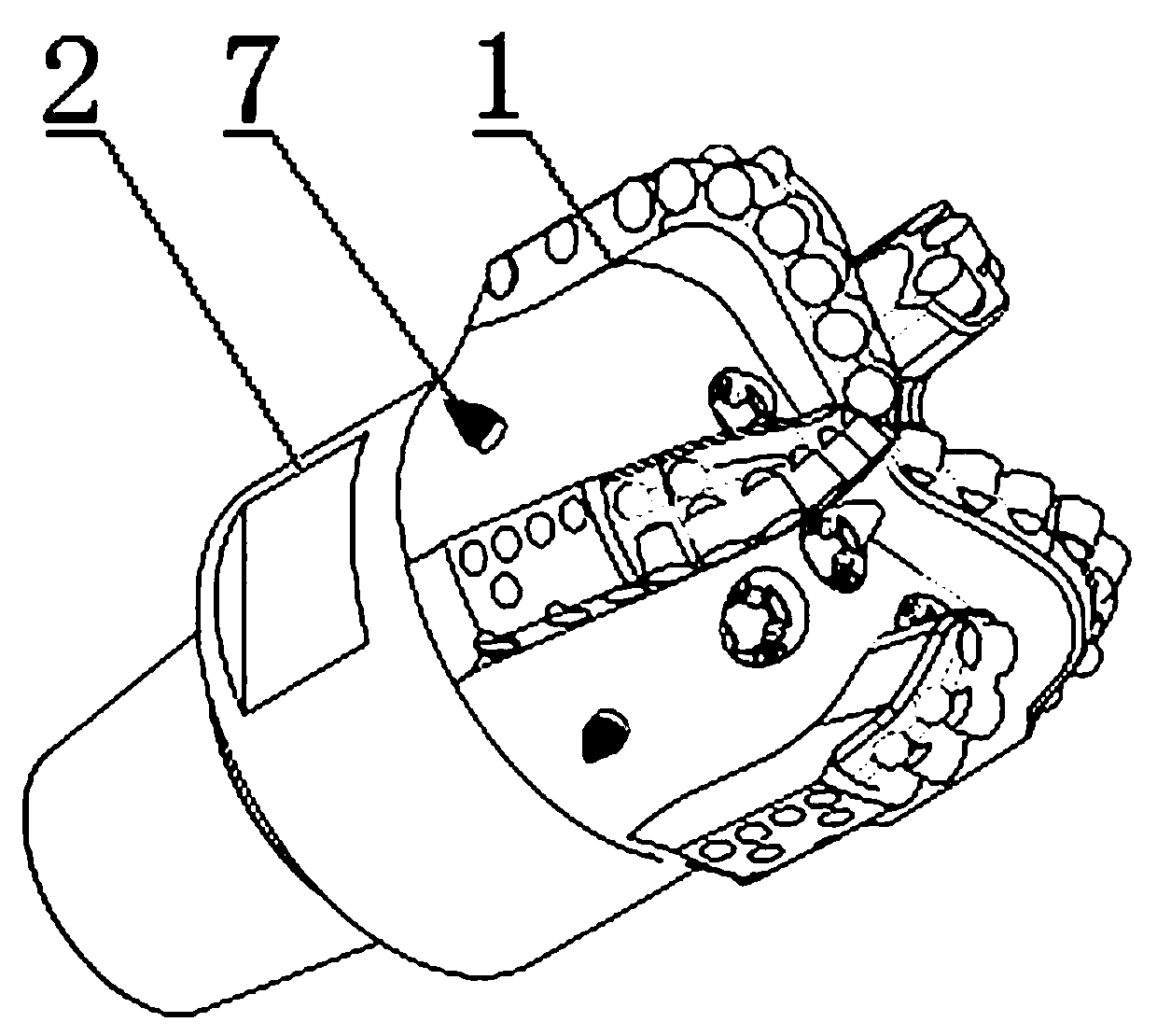

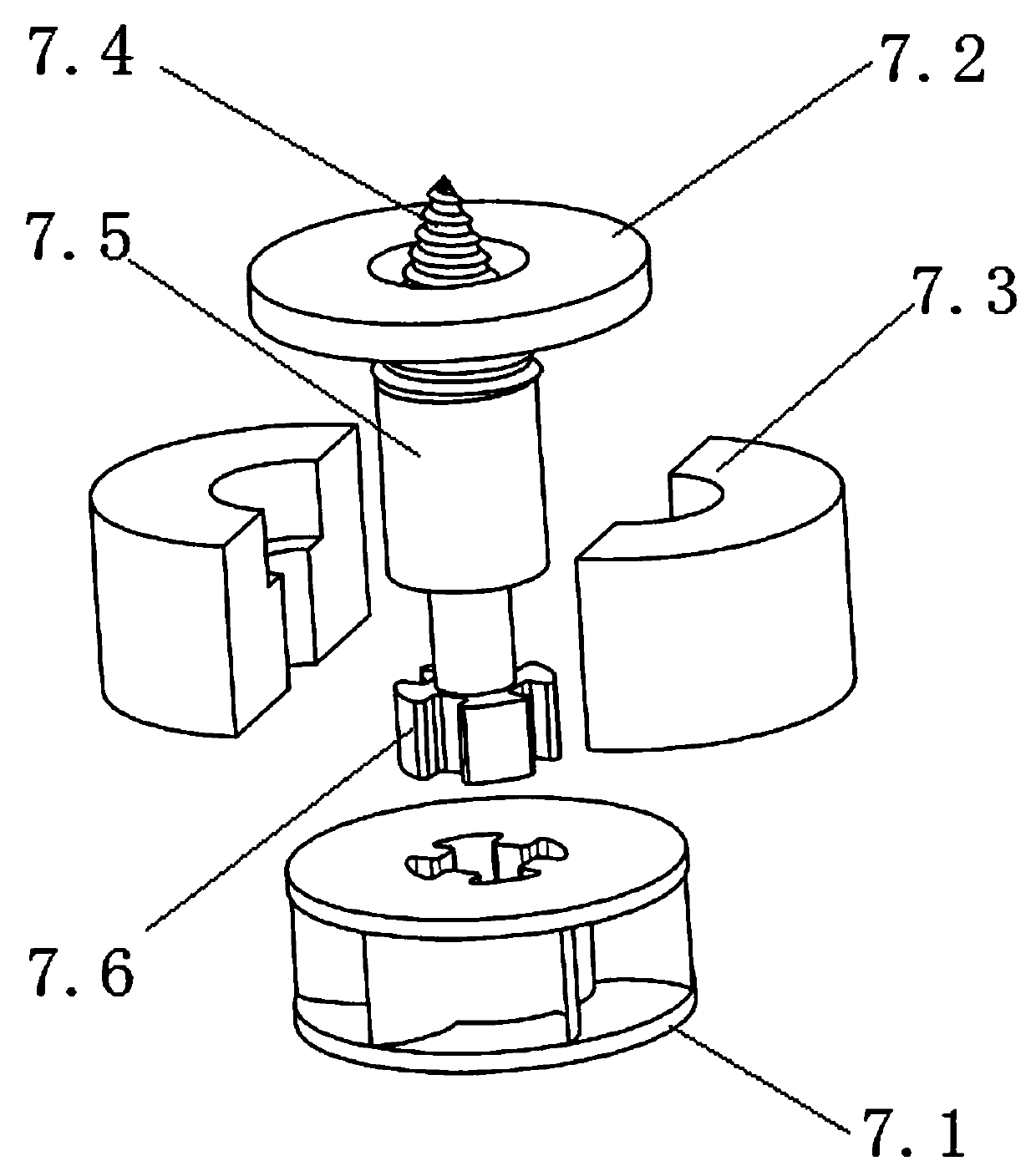

[0030] As a most basic embodiment of the present invention, such as figure 1 and 2 , discloses an active anti-jamming PDC drill bit with a rotary rock breaking device, including a drill body 2 provided with a cutter head 1, a plurality of drill blade blades 3 are arranged on the cutter head 1, and a knife blade is formed between the drill blade blades 3. The outer flow channel 4 on the side of the head 1, the cutter head 1 and the drill bit body 2 are provided with an inner flow channel 5 communicating with the fluid, and the fluid flows into the inner flow channel 5 from the end of the drill body 2 and passes through the drill bit body 2 and the inside of the cutter head 1 flow out from the outlet 6 at the front end of the cutter head 1; in the outer flow channel 4 of the cutter head 1, a rotating rock breaking device 7 is provided, and the rotating rock breaking device 7 includes a bottom for being arranged on the The impeller 7.1 in the inner flow channel 5 of the cutter h...

Embodiment 2

[0033] As a preferred embodiment of the present invention, preferably, such as figure 1 , the inner diameter of the inner flow channel 5 in the drill body 2 is greater than the inner diameter of the inner flow channel 5 in the cutter head 1, that is, the fluid in the inner flow channel 5 in the drill body 2 enters the inner flow channel in the cutter head 1 At 5 o'clock, a certain pressure difference is generated due to the flow difference, so that when entering the inner flow channel 5 of the cutter head 1, there is a greater impact force, which is more convenient to drive the rotary rock breaking device 7, and the inner part of the drill bit body 2 The flow channel 5 is located on the central axis of the drill body 2, and the inner flow channel 5 in the cutter head 1 is arranged along the direction of the outer flow channel 4 on the side of the cutter head 1 from the connecting end with the drill body 2, so that it can be placed on the drill body 2 and the inner runner 5 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com