Large-size reinforced concrete target plate penetration hole three-dimensional contour measurement method

A technology of reinforced concrete and three-dimensional contours, which is applied in the direction of measuring devices, surveying and navigation, instruments, etc., can solve the problems of high-precision measurement of the internal shape of difficult bullet holes, narrow bullet holes, and difficult implementation of large-scale reinforced concrete target plates, etc. Achieve the effect of reducing labor intensity and safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

[0037] In this application document, unspecified component models and structures are all prior art known to those skilled in the art, and those skilled in the art can set them according to the needs of the actual situation. In the embodiments of this application document No specific restrictions are made.

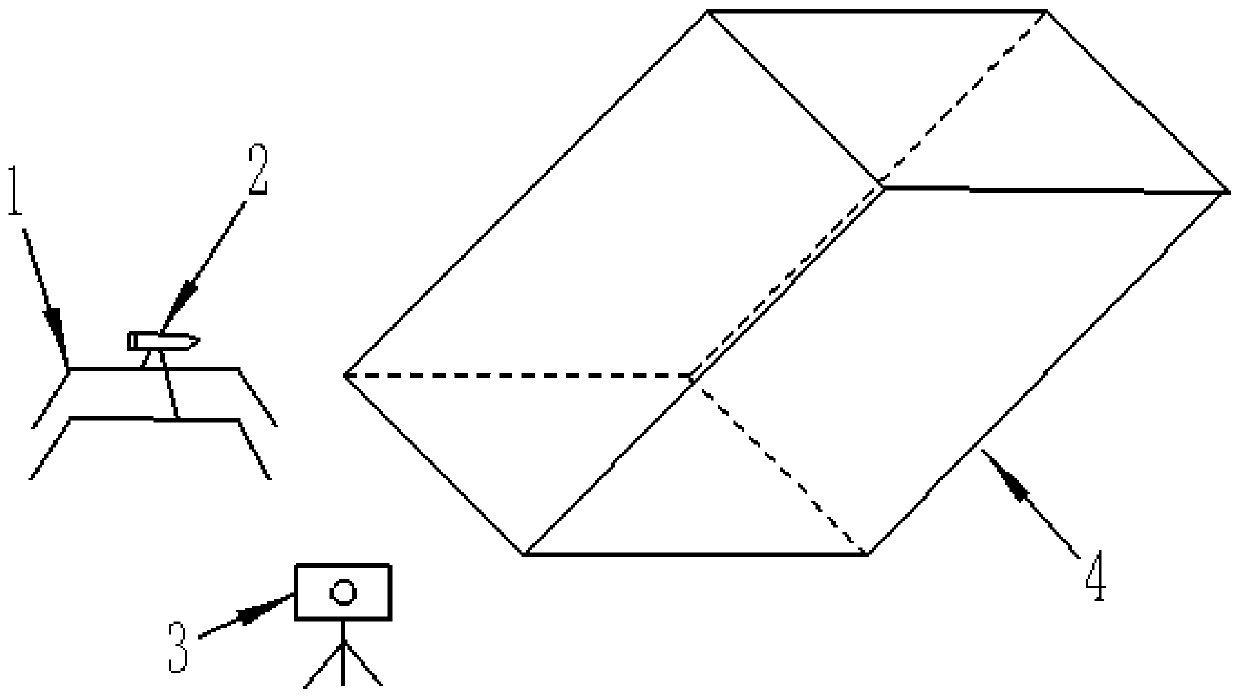

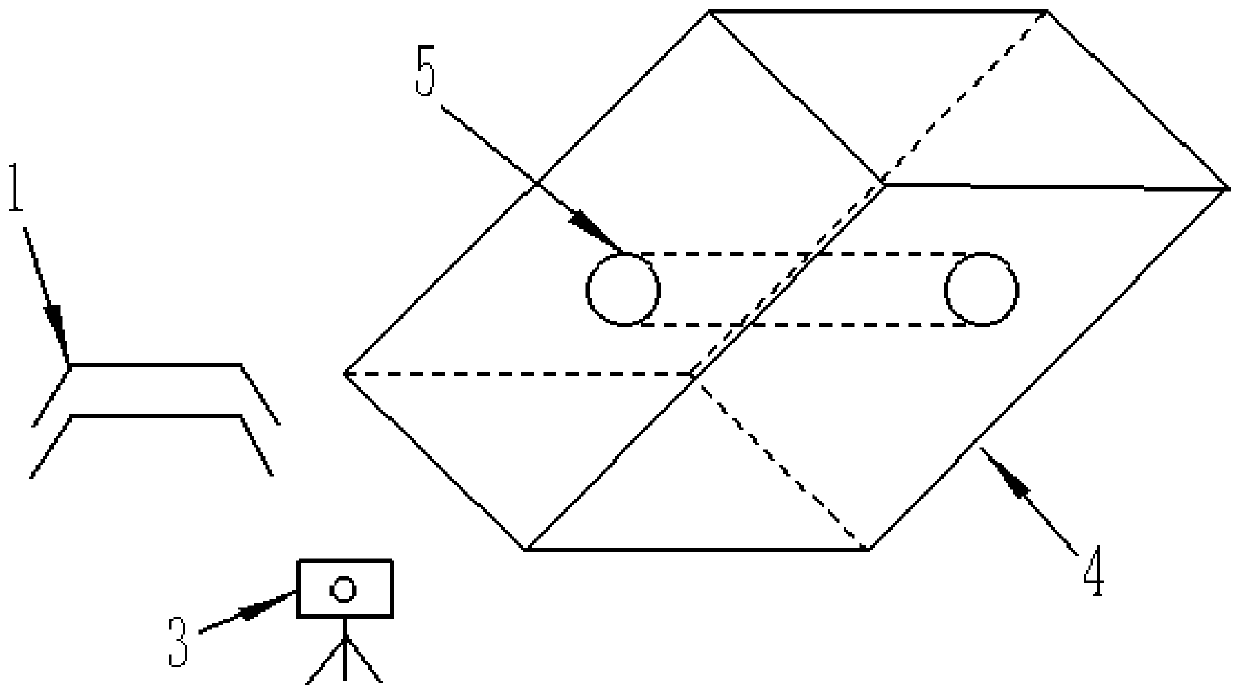

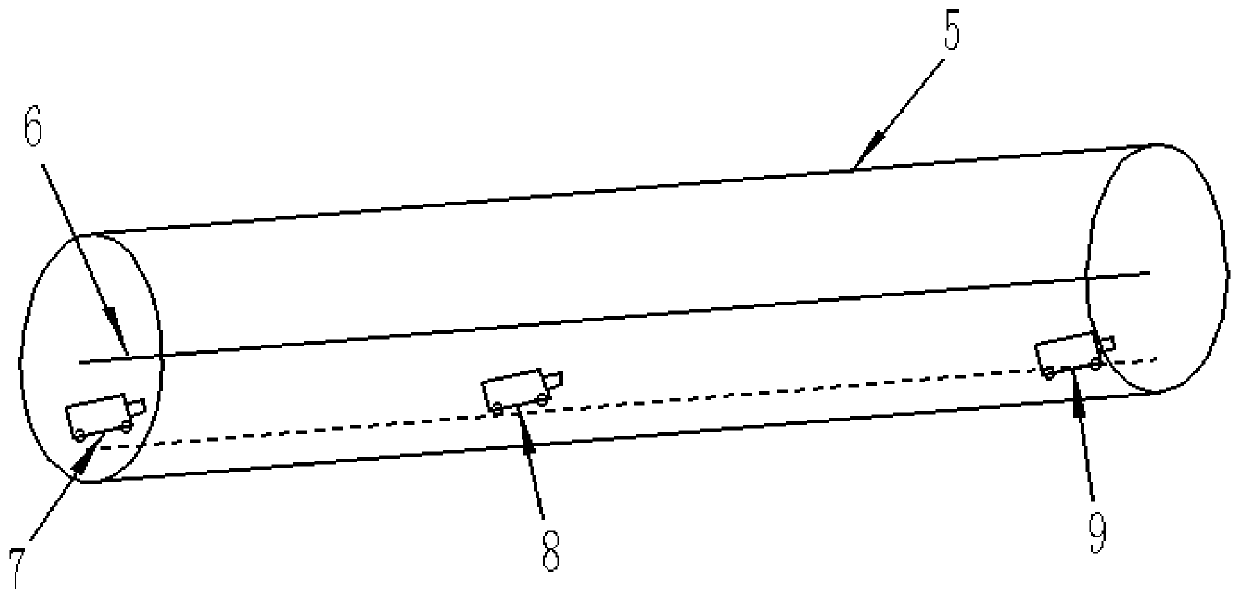

[0038] Specifically, such as Figure 1-4 Shown, the embodiment of the present invention provides a kind of large size (the thickness of the reinforced concrete target plate is more than 1m in size is large size) reinforced concrete target plate penetrating bullet hole three-dimensional profile measurement method:

[0039] Use the scanner to scan the outer contour and spatial position of the target plate 4 and the rocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com