Machine tool manufacturing BOM storage query and tree structure construction method based on MES system

A tree structure and construction method technology, which is applied in manufacturing computing systems, structured data retrieval, instruments, etc., can solve problems such as prone to errors, inconvenient use of manufacturing BOM, time-consuming, etc., to achieve rapid positioning and speed up upgrades and updates Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

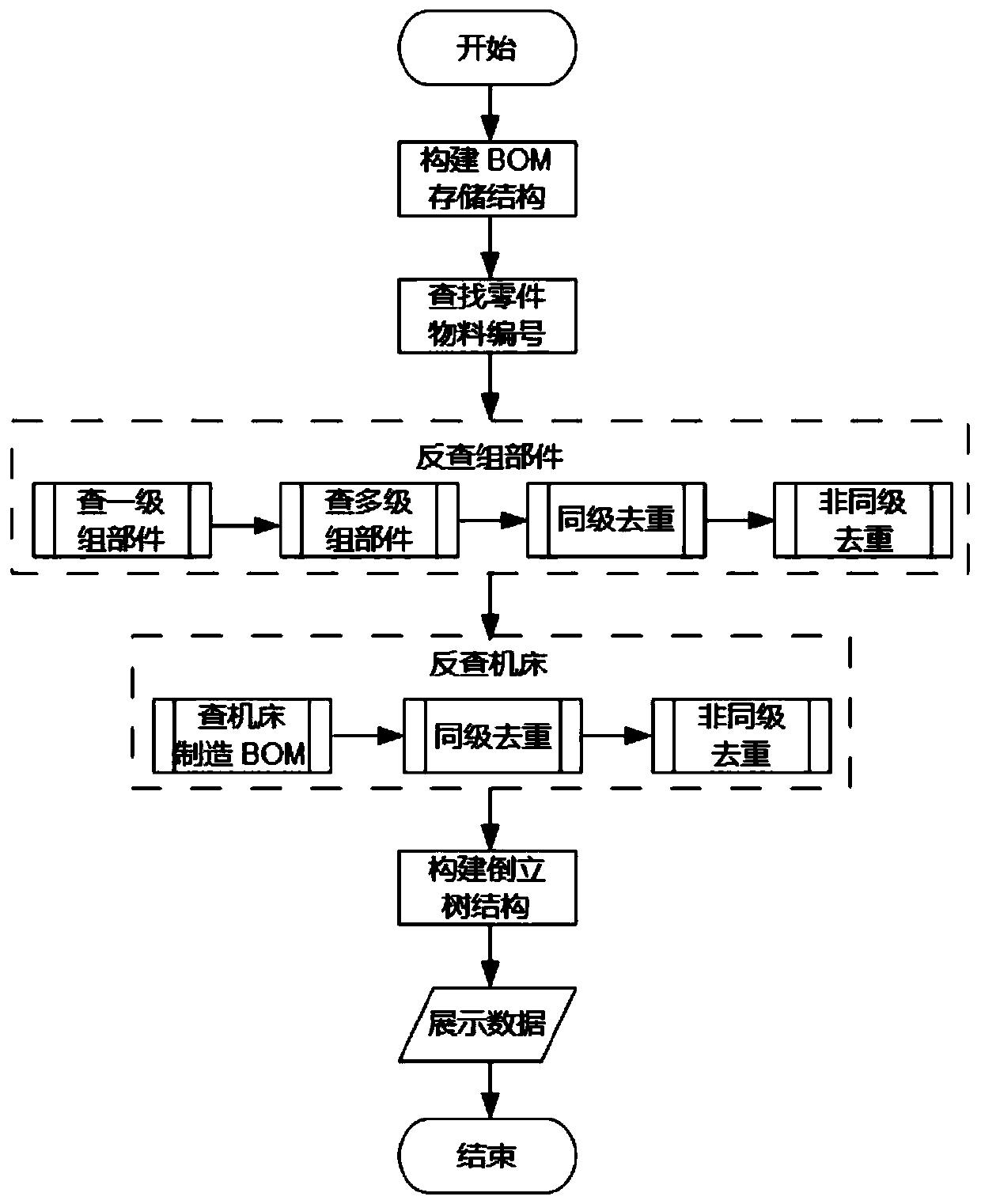

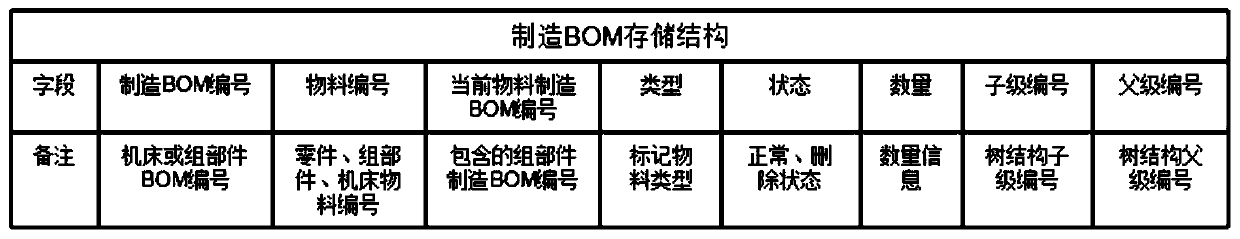

[0083] The invention provides a BOM storage query and tree structure construction method for machine tool manufacturing based on the MES system, which is convenient for the BOM reverse check operation on the production site, can not only improve the query efficiency, but also ensure the correctness, and provide automatic query manufacturing BOM, automatic Eliminate duplicate data, automatically build an inverted tree structure, without manual participation, and the output results are clear and clear. It can directly provide support for batch upgrades of machine tool manufacturing BOM, with high reliability and accuracy.

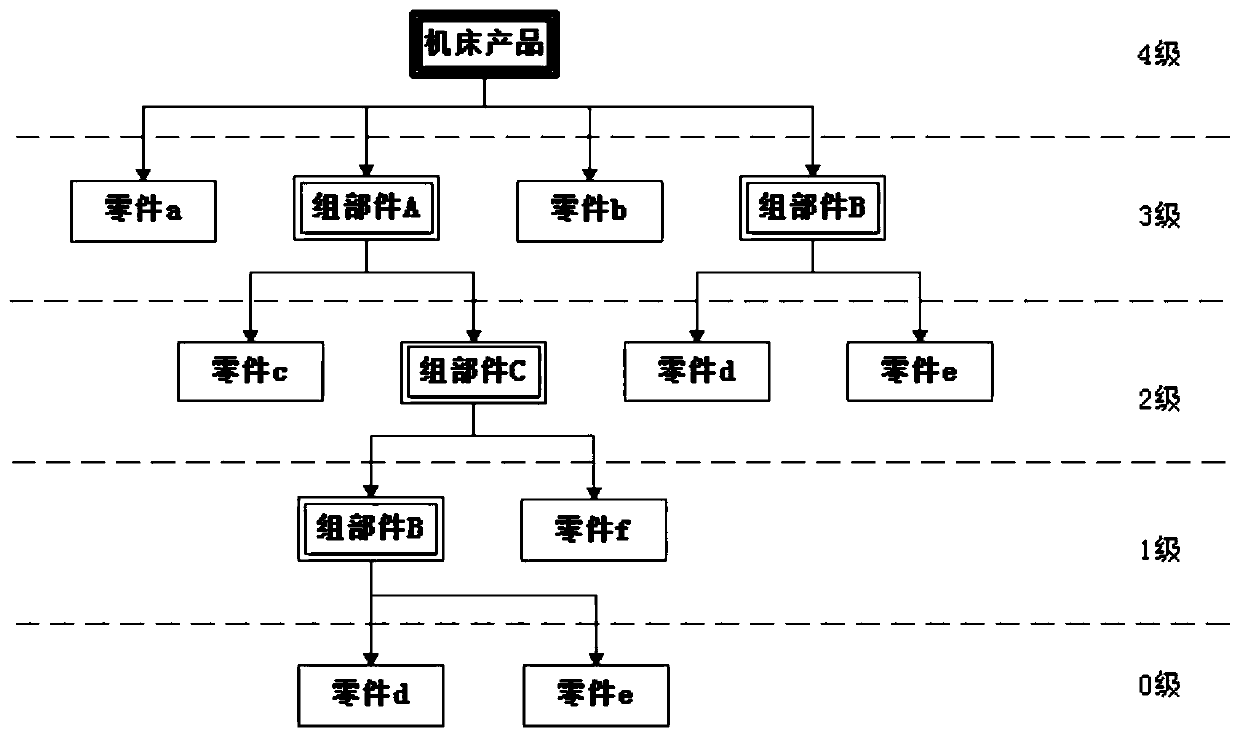

[0084] Among machine tool group parts, first-level group parts: group parts that directly contain specific materials; multi-level group parts: group parts that directly contain first-level group parts; third-level group parts: group parts that directly contain second-level group parts; and so on , two-level and above group components are called multi-level gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com