Soft package battery and manufacturing method thereof

A soft pack battery, manufacturing method technology, applied in secondary battery manufacturing, battery pack components, final product manufacturing, etc. Chemical properties, improved mechanical strength, high mechanical strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

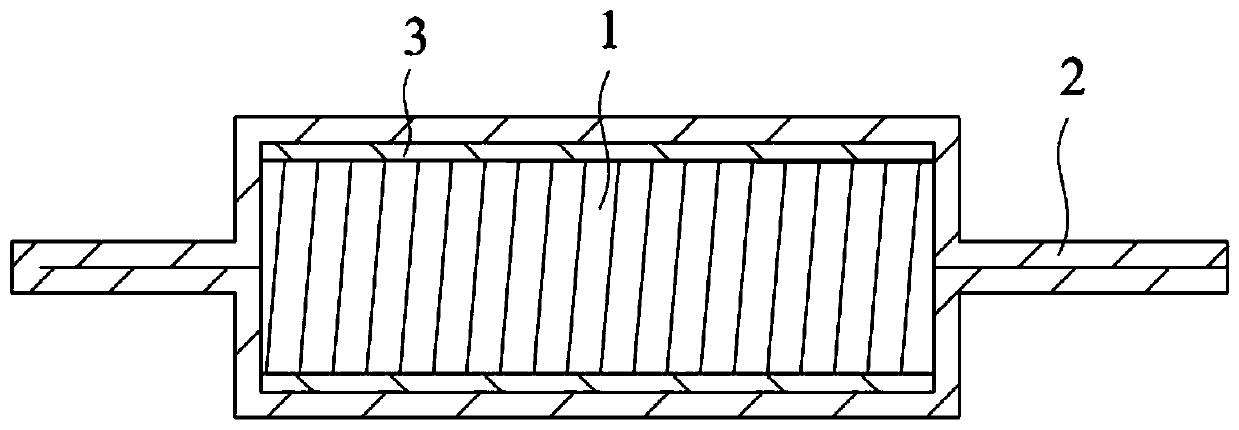

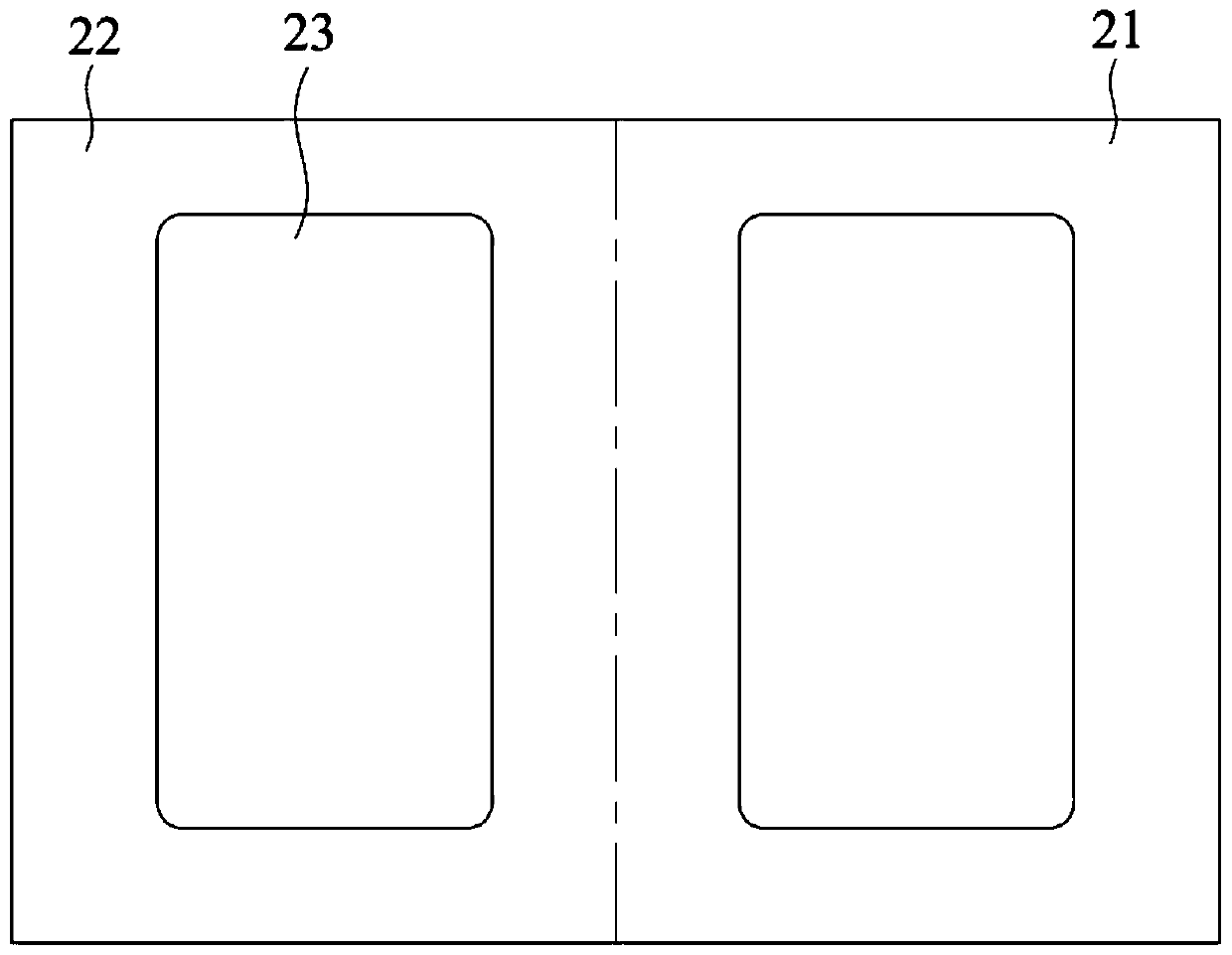

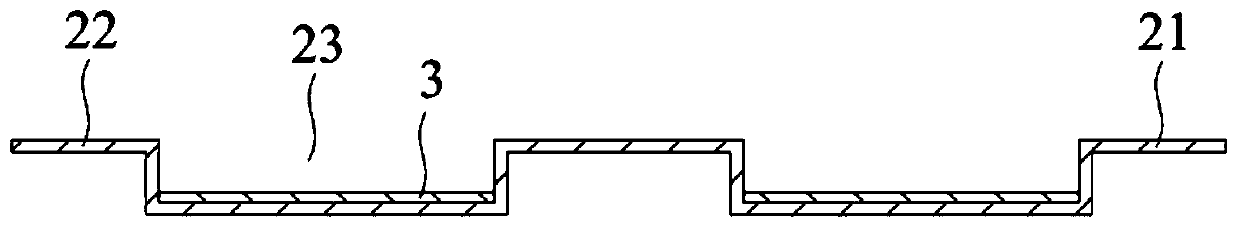

[0041] like Figure 1-3 As shown, a pouch battery proposed in this embodiment includes a cell body 1 , an aluminum-plastic film 2 and a reinforcement layer 3 . Among them, the aluminum-plastic film 2 is provided with a punching hole 23 for accommodating the cell body 1, and the cell body 1 is packaged in the punching hole 23 in the aluminum-plastic film 2; The layer 3 is interposed between the cell body 1 and the aluminum-plastic film 2 , and the reinforcing layer 3 is located in the punching pit 23 . In the pouch battery of this embodiment, on the premise that the cell body 1 is packaged in the punching hole 23 of the aluminum-plastic film 2, and the structure of the aluminum-plastic film 2 and the cell body 1 is not changed, the aluminum-plastic film 2 A reinforcement layer 3 with a thickness smaller than the depth of the punching pit 23 is added in the punching pit 23, which improves the mechanical strength of the pouch battery, makes the pouch battery not easy to deform, ...

Embodiment 2

[0048] This embodiment proposes a method for manufacturing a pouch battery, which is used to manufacture the pouch battery in Example 1. The method for manufacturing a pouch battery mainly includes the following steps:

[0049] Material preparation: provide the cell body 1, the aluminum-plastic film 2 with a planar structure, and the reinforcement layer 3;

[0050] Punching treatment: stamping on the aluminum-plastic film 2 to form a punching pit 23 for accommodating the cell body 1;

[0051] Filling the reinforcement layer: placing the reinforcement layer 3 in the punching pit 23;

[0052] Packaging the cell body: place the cell body 1 in the punching pit 23, and package the cell body 1.

[0053] The pouch battery manufactured by the manufacturing method of the pouch battery in this embodiment has the advantages of high mechanical strength and not easily deformed due to the addition of a reinforcement layer 3 in the punching pit 23; at the same time, the reinforcement layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com