Negative electrode material of high-power lithium battery, preparation method and lithium battery

A negative electrode material, lithium battery technology, applied in electrode manufacturing, battery electrode, electrode current collector coating, etc. The problem of high uniformity degree correlation, etc., can achieve good slurry dispersion effect, improve electronic and ionic conductivity, and reduce slurry mixing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

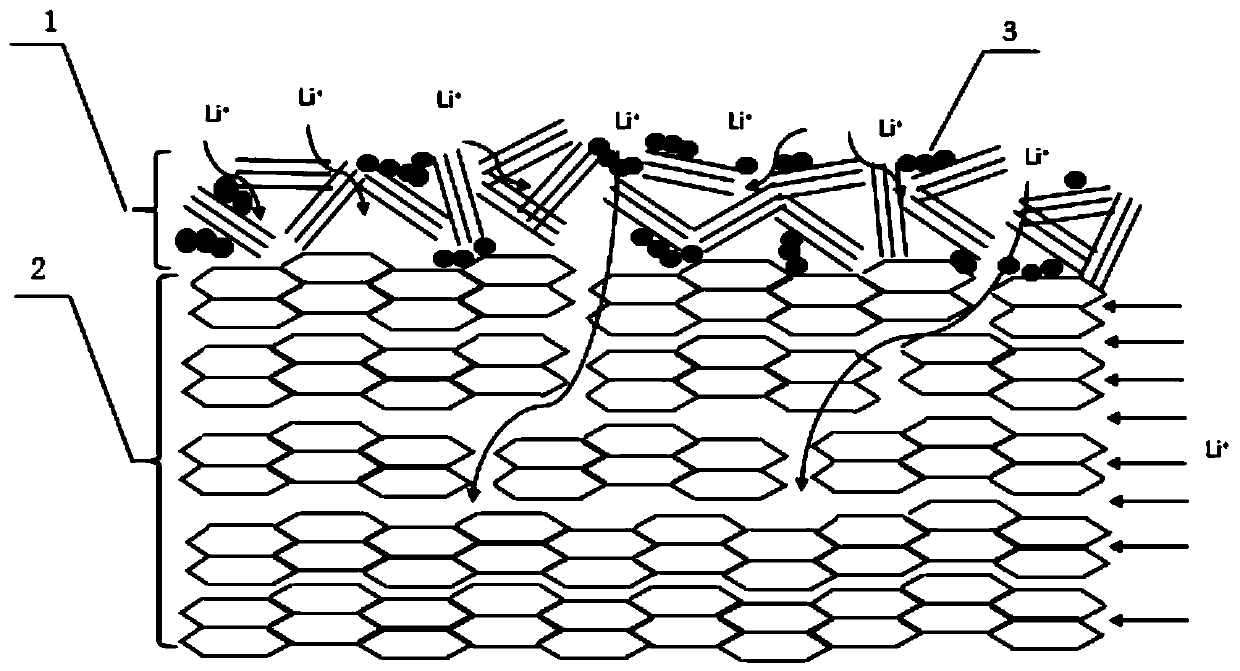

Image

Examples

Embodiment 1

[0039] (1) Preparation of modified artificial graphite negative electrode material:

[0040] D50 is 4 μ m small particle size graphite material mixed with 15wt% strong alkali KOH solution, and filtered at 75 ° C after stirring for 48 hours, after cleaning, the graphite material A whose surface corrosion produces a porous structure is obtained; graphite material A 93% , corn starch 6%, and conductive carbon black sp 1% are fused with a mechanical fusion machine for 1h to obtain graphite-coated precursor B; then graphite-coated precursor B is placed in a graphite crucible, and put into N 2 Carry out carbonization in an atmosphere furnace protected by inert gas. The carbonization temperature is controlled at 1300°C, and the temperature is maintained for 20 hours. Finally, it is cooled to room temperature at 25°C, and airflow crushing is carried out to obtain a surface-coated modified high-power lithium-ion battery graphite negative electrode. Material.

[0041] (2) Preparation o...

Embodiment 2

[0046] The preparation of the modified artificial graphite negative electrode material and the battery preparation process of Example 2 and Example 1 are the same, the difference lies in the preparation of the first step premix in the negative electrode sheet preparation process: the modified negative electrode material is coated on the surface Together with the hard carbon as the negative electrode active material, the negative electrode material that is about to be coated with the surface and the hard carbon material and the conductive carbon black are added together in a strong mixer and premixed for 5 minutes to obtain a premixed material. The other slurry mixing steps are the same as in Example 1. In one hundred parts by weight of negative electrode slurry (negative electrode material+hard carbon): conductive agent: CMC: SBR = (90-97): (0-5): (1-2): (1-3).

Embodiment 3

[0048] The preparation of the modified artificial graphite negative electrode material and the battery preparation process of Example 3 and Example 1 are the same, the difference lies in the preparation of the first step premix in the negative electrode sheet preparation process: the surface is coated with the modified negative electrode material Together with soft carbon as negative electrode active material, the negative electrode material with surface coating modification, soft carbon material and conductive carbon black are added together in a strong mixer for premixing for 5 minutes to obtain a premixed material, and other slurry mixing steps are the same as in Example 1. In one hundred parts by weight of negative electrode slurry (negative electrode material + soft carbon): conductive agent: CMC: SBR = (90-97): (0-5): (1-2): (1-3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap