Electromagnetic pump structure

An electromagnetic pump and outer cylinder technology, applied in the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc., can solve the problems of high coil failure rate and high heat resistance requirements, and achieve low noise and vibration, The effect of reducing temperature and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

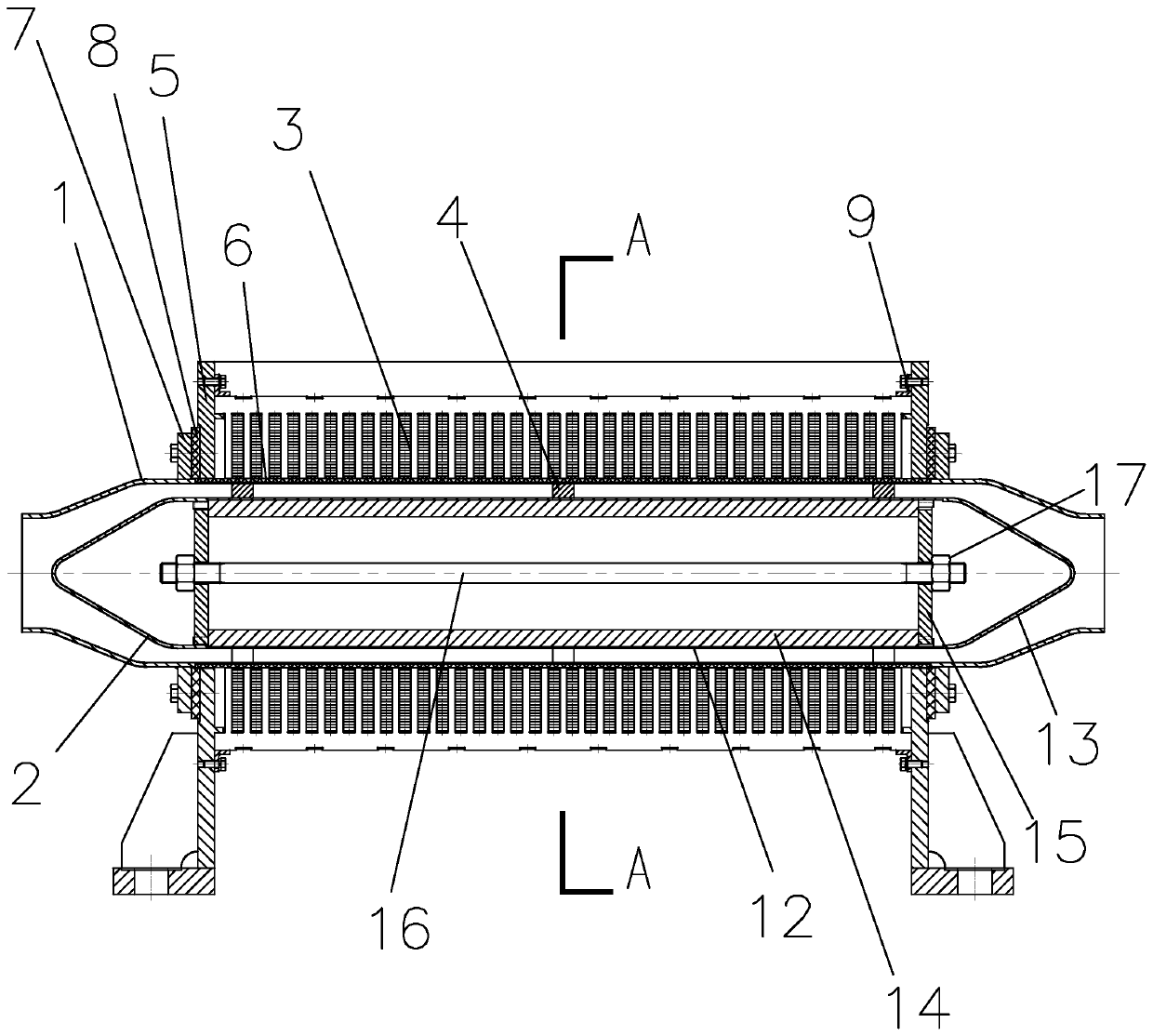

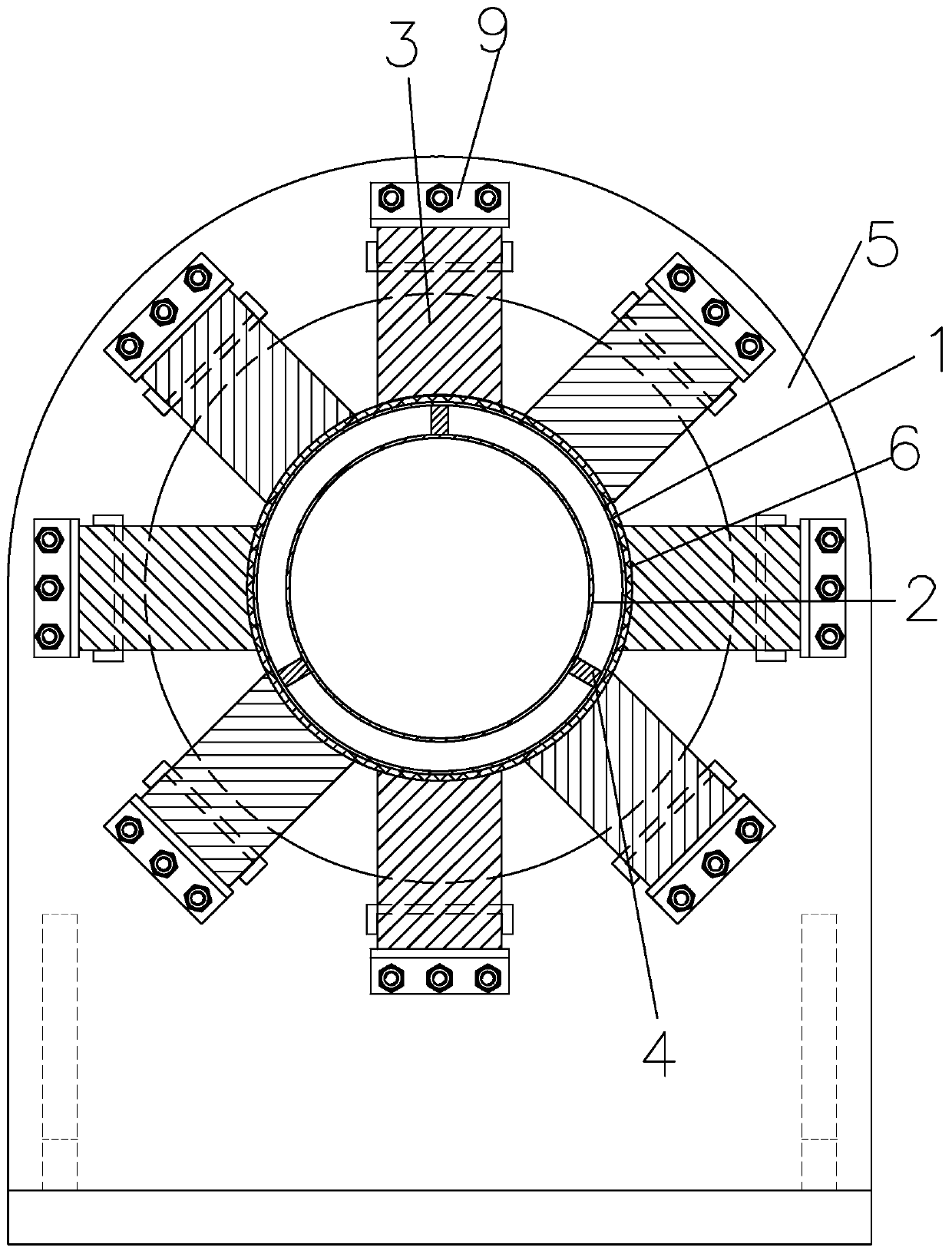

[0018] see Figure 1 to Figure 2 ; An electromagnetic pump structure, including an outer cylinder, an inner cylinder located in the outer cylinder, eight outer iron cores located outside the outer cylinder, a coil group placed in the groove of the outer iron core, and between the outer cylinder and the inner cylinder The pads used to support the inner cylinder, the material of the outer cylinder and the inner cylinder are all austenitic stainless steel; it also includes a heat insulation pad wrapped outside the outer cylinder, the heat insulation pad is located between the outer iron core and the outer cylinder, The outer iron core has a long strip structure, the axis of the outer iron core is parallel to the axis of the outer cylinder, and the outer iron core is arranged in a circular array centered on the axis of the outer cylinder, and the two ends of the heat insulation pad are covered with A support plate is provided, the outer iron core is located between the support pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com