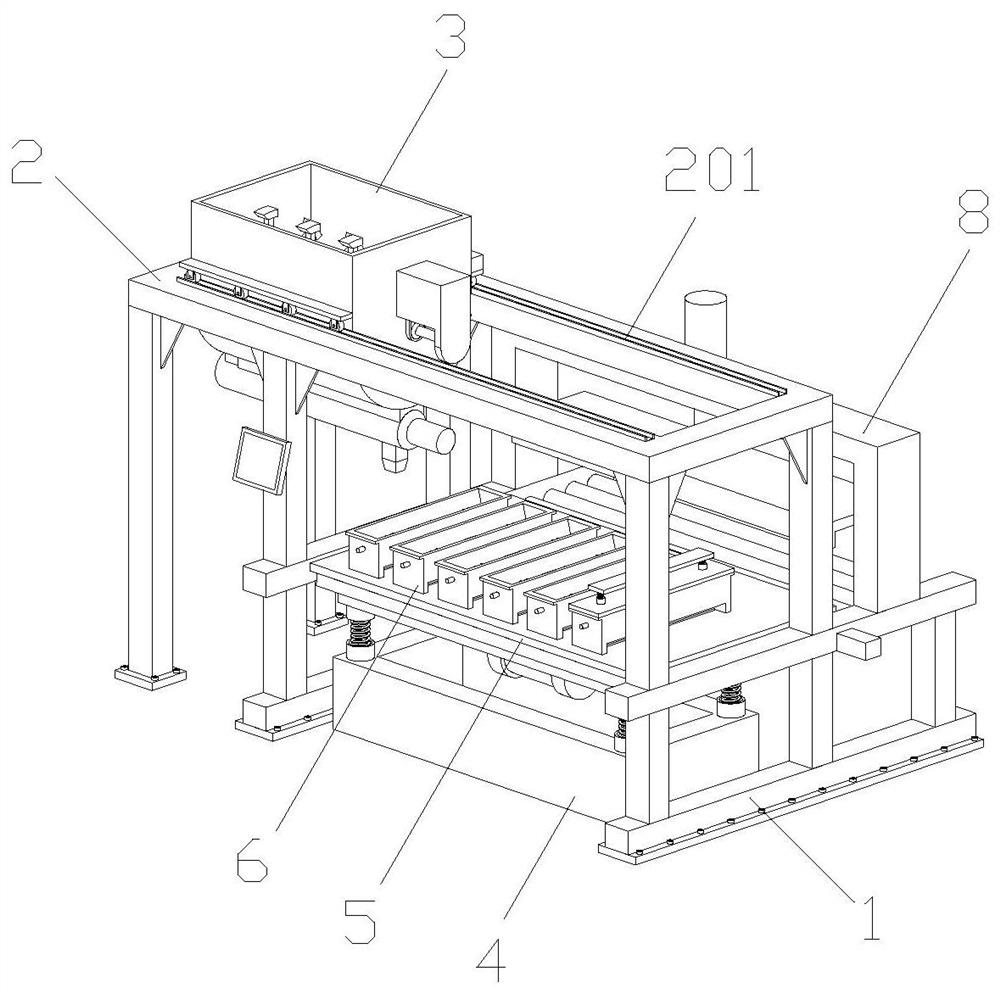

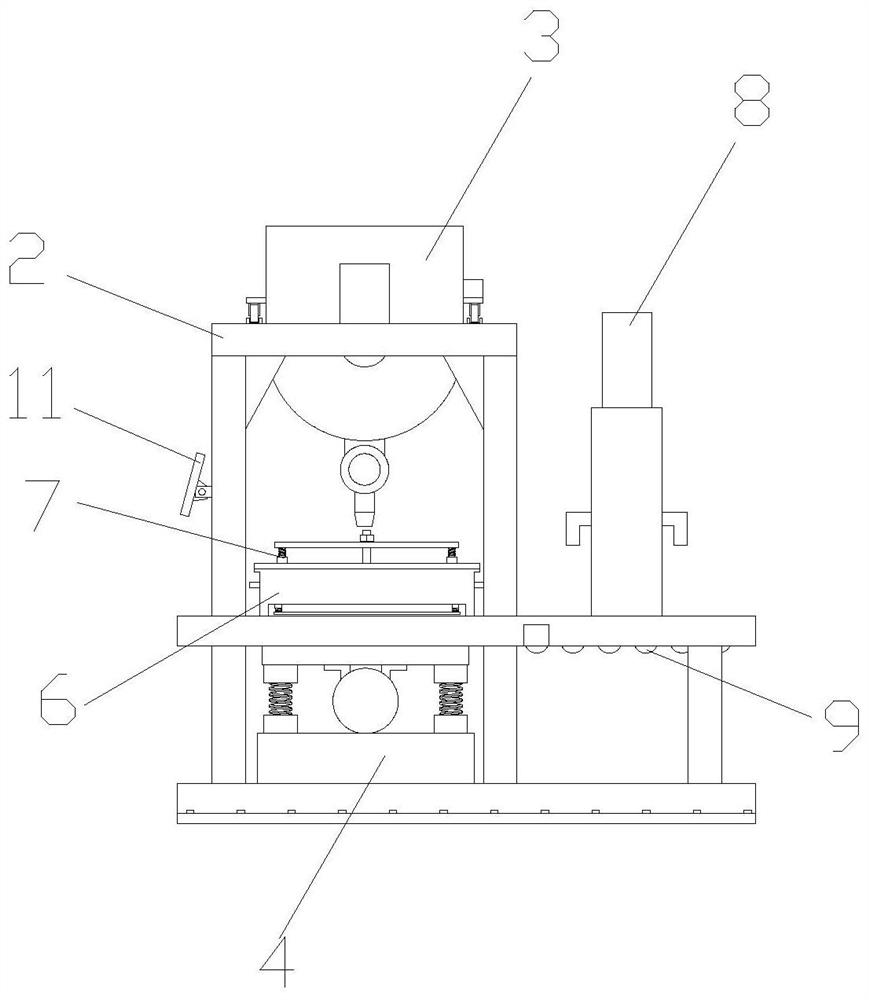

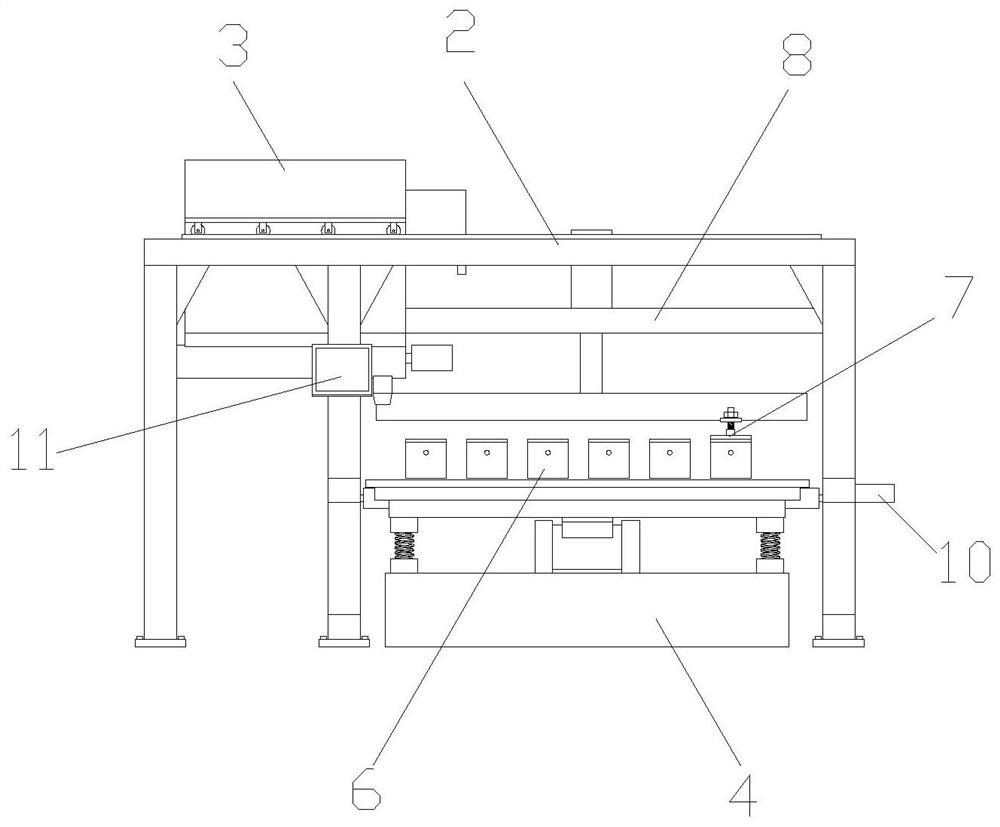

A prefabricated sleeper and its production equipment and method

A production method and sleeper technology, applied in the field of prefabricated sleepers and their production equipment, can solve problems such as increased ballast pressure and vibration acceleration, adverse effects of locomotives and vehicles running, increased track sinking, etc., to achieve improved compactness and improved Basic mechanical properties, the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A prefabricated sleeper, comprising the following raw materials in parts by weight: 90 parts of Portland cement, 50 parts of graded gravel, 110 parts of medium-coarse river sand, 60 parts of microsilica, 2 parts of steel fiber, 5 parts of basalt fiber, methyl 0.2 part of cellulose ether, 0.5 part of hydroxyalkyl starch ether, and 0.5 part of naphthalene-based superplasticizer.

[0072] Its preparation method comprises the following steps:

[0073] (1) Use automatic tensioning equipment to stretch the low-relaxation spiral rib prestressed steel wire with a diameter of 6.25mm, the tension speed is ≤80kN / s, and the limit deviation of prestressed steel wire cutting is less than 1.5 / 10000 of the length of the steel wire. The ribs, spiral ribs and sleeves are fixed in the prefabricated mould;

[0074] (2) Add the raw materials of the prefabricated sleeper into the mixing tank, add water with 25% of the total mass of the raw materials and stir for 120s to obtain the concrete ...

Embodiment 2

[0080] A prefabricated sleeper, comprising the following raw materials in parts by weight: 80 parts of Portland cement, 45 parts of graded gravel, 100 parts of medium-coarse river sand, 55 parts of microsilica, 2 parts of steel fiber, 6 parts of basalt fiber, methyl 0.5 parts of cellulose ether, or 0.2 parts of carboxymethyl starch ether, and 0.5 parts of amino superplasticizer.

[0081] Its preparation method comprises the following steps:

[0082] (1) Use automatic tensioning equipment to stretch the low-relaxation spiral rib prestressed steel wire with a diameter of 6.5mm, the tension speed is ≤80kN / s, and the limit deviation of prestressed steel wire cutting is less than 1.5 / 10000 of the length of the steel wire. The ribs, spiral ribs and sleeves are fixed in the prefabricated mould;

[0083] (2) Add the raw materials of the prefabricated sleeper into the mixing tank, add water with 30% of the total mass of the raw materials and stir for 120s to obtain the concrete slurry...

Embodiment 3

[0089] A prefabricated sleeper, comprising the following raw materials in parts by weight: 100 parts of Portland cement, 40 parts of graded gravel, 120 parts of medium-coarse river sand, 65 parts of microsilica, 3 parts of steel fiber, 3 parts of basalt fiber, methyl 0.5 part of cellulose ether, 0.2 part of cationic starch ether, and 1 part of polycarboxylate superplasticizer.

[0090] Its preparation method comprises the following steps:

[0091] (1) Use automatic tensioning equipment to stretch the low-relaxation spiral rib prestressed steel wire with a diameter of 6.25mm, the tension speed is ≤80kN / s, and the limit deviation of prestressed steel wire cutting is less than 1.5 / 10000 of the length of the steel wire. The ribs, spiral ribs and sleeves are fixed in the prefabricated mould;

[0092] (2) Add the raw materials of the prefabricated sleeper into the mixing tank, add water with 20% of the total mass of the raw materials and stir for 150s to obtain the concrete slurry;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com