Leveling platform of fusion deposition type 3D printer

A 3D printer, fused deposition technology, applied in the processing platform/substrate, 3D object support structure, additive manufacturing, etc., can solve the problems of long adjustment time, uneven plane, difficult adjustment, etc., and minimize the leveling error , improve leveling efficiency, and simplify the platform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

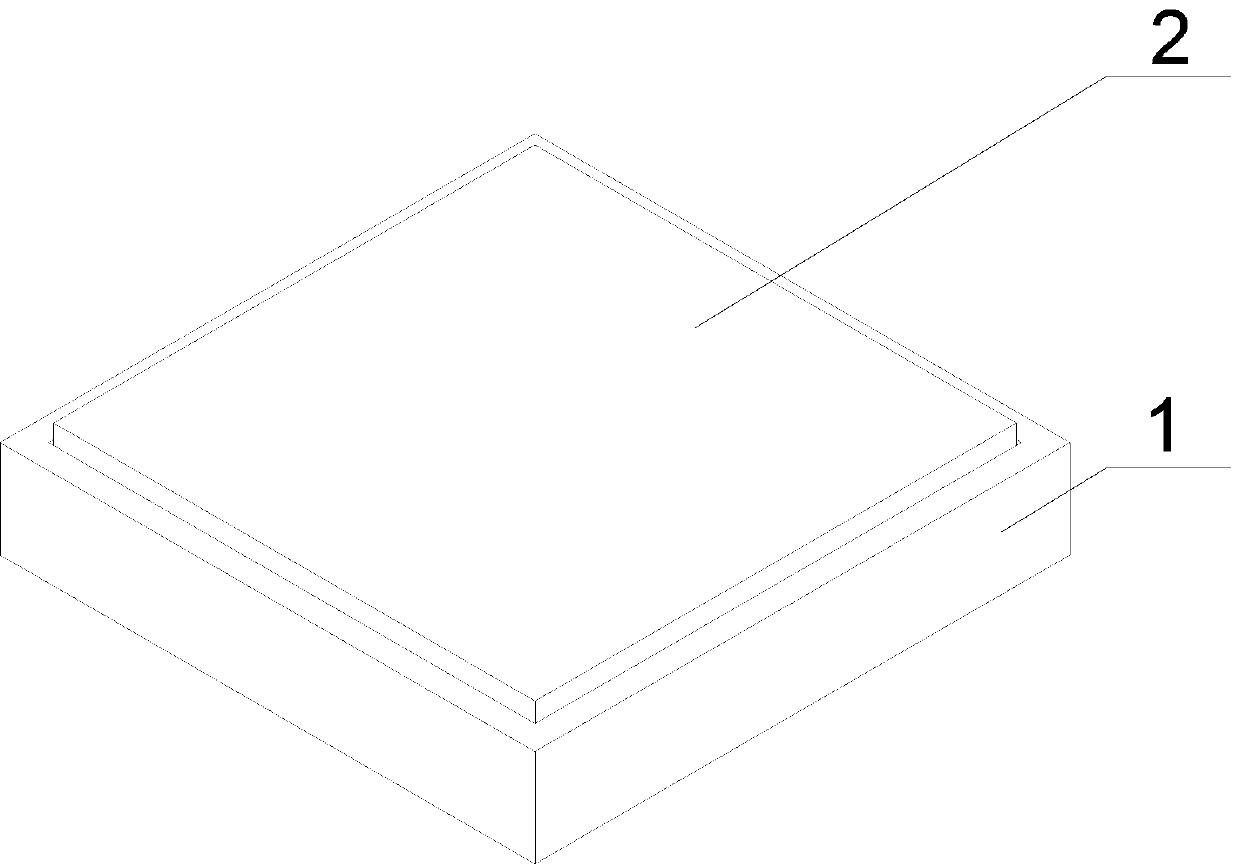

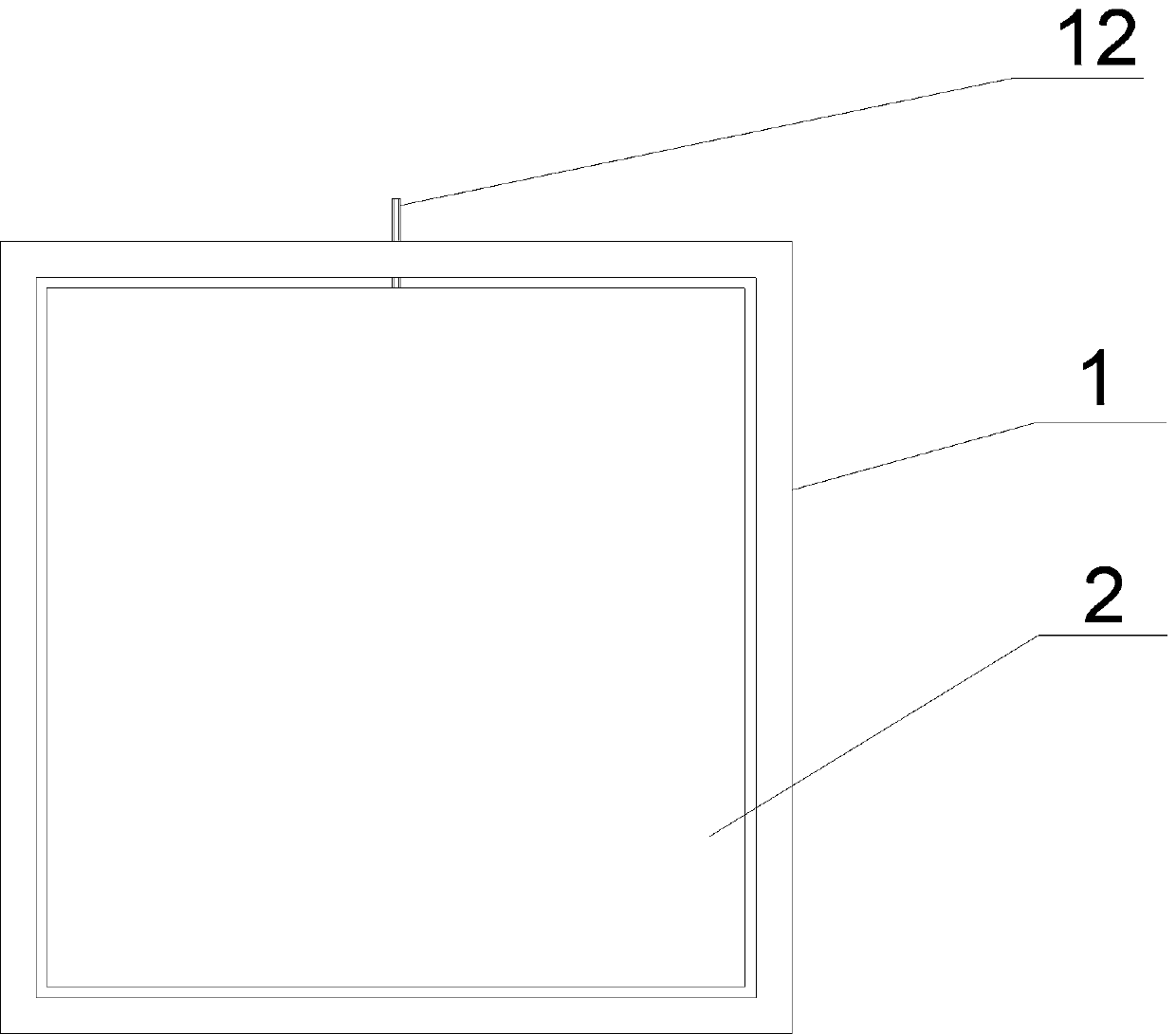

[0021] Such as figure 1 As shown, the present invention is a leveling platform of a fused deposition type 3D printer, comprising: a liquid accumulation tank 1 and a printing platform 2, the liquid accumulation tank 1 is a box with an open top, and the printing platform 2 is located in the liquid accumulation tank 1 , there is a filler 11 in the effusion tank 1. During the leveling process, the filler is in a liquid state. At this time, the printing platform floats on the filler under the action of buoyancy. According to the buoyancy formula Ffloat=ρliquid It can be seen from the gV row that those skilled in the art can select the material and structure of the printing platform and the density of the filling according to the needs, so as to ensure that the filling can use the buoyancy to float the printing platform. In this embodiment, the filler 11 is introduced as an example of liquid water, and the printing platform 2 can be selected as Figure 5 As shown in the box body wi...

Embodiment 2

[0023] The difference between embodiment 2 and embodiment 1 is that the filler 11 in embodiment 2 is a material that can be converted from a liquid state to a solid state. The filler 11 is a mixture of epoxy resin and epoxy resin curing agent as an example. When the epoxy resin and epoxy resin curing agent are mixed and put into the effusion tank 1, they are in a liquid state. After they are put into the printing platform 2, natural gravity is used to achieve natural leveling. After standing still for a period of time, the epoxy resin and epoxy resin The resin curing agent mixture is solidified, and at this time the printing platform 2 is fixed together with the epoxy resin and the epoxy resin curing agent mixture. Embodiment 2 Compared with Embodiment 1, the filling 11 in a solidified state after leveling is more convenient to use than the filling 11 in a liquid state all the time.

Embodiment 3

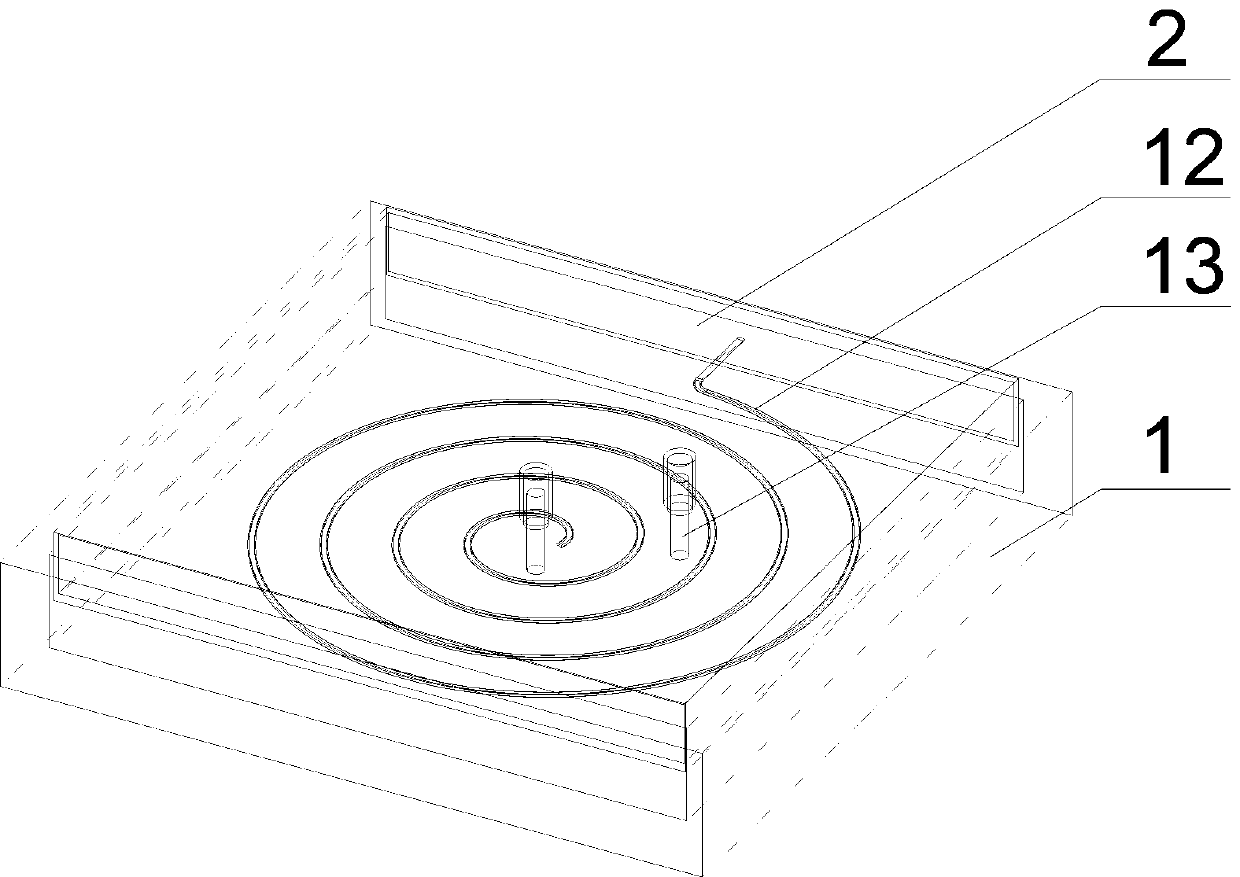

[0025] The difference between embodiment 3 and embodiment 1 and embodiment 2 is that the leveling platform of the fused deposition 3D printer also includes a heating device 12 for heating the filling in the liquid accumulation tank 1, and the filling 11 is The material that can be converted between liquid and solid is introduced by taking EVA resin (commonly known as hot melt adhesive) as the filler 11 as an example. The EVA resin in the effusion tank 1 is heated by the heating device 12, and the heated EVA resin is converted from solid state into a liquid state, then put it into the printing platform 2, and use natural gravity to achieve natural leveling. After leveling, turn off the heating device 12, and the EVA resin will solidify into a solid after standing for a period of time at room temperature; For leveling, it is only necessary to heat the filling material 11 in the liquid accumulation tank 1 through the heating device 12, and so on, so as to achieve multiple leveling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com