High-porosity thin microporous composite ceramic plate and preparation method thereof

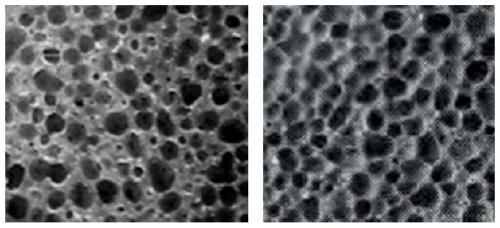

A technology of porosity and ceramic plates, applied in the field of high-porosity thin foamed composite ceramic plates and its preparation technology, can solve the problems of low foaming degree, rough surface of foamed ceramic plates, poor interlayer bonding strength, etc., and achieve reduction The effect of firing temperature, reducing firing time, and avoiding fusion between pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0121] Preparation of pre-foamed base ceramic blank 1

[0122] 1) choose raw material powder by following weight parts:

[0123] 50 parts of pottery clay, 20 parts of kaolin, 20 parts of potassium sodium feldspar, 15 parts of expanded perlite powder, 10 parts of diopside, 5 parts of quartz sand, 5 parts of bentonite, 1 part of fluorite powder, silicon carbide and carbonic acid in equal weight ratio 4.5 parts of inorganic foaming agent composed of lithium and magnesium carbonate, 2 parts of borax, 1.5 parts of azodicarbonamide, 1.5 parts of 30-50 μm chopped glass fiber, and 0.5 part of polyvinyl alcohol. Wherein, about 65-66 wt% of silicon dioxide, about 12.5-13 wt% of potassium oxide and about 4.5-5.0 wt% of sodium oxide in the potassium albite feldspar.

[0124]2) mix the clay, kaolin, potassium albite, expanded perlite powder, diopside, quartz sand, bentonite, fluorite powder and borax raw material powder components in the above proportions, and grind them with a grinder to...

preparation example 2

[0134] Preparation of pre-foamed base ceramic blank 2

[0135] 1) choose raw material powder by following weight parts:

[0136] 45 parts of pottery clay, 25 parts of kaolin, 20 parts of potassium sodium feldspar, 16 parts of expanded perlite powder, 12 parts of diopside, 7 parts of quartz sand, 6 parts of bentonite, 2 parts of fluorite powder, silicon carbide and carbonic acid in equal weight ratio 4 parts of inorganic foaming agent composed of magnesium, 2 parts of borax, 1 part of azodicarbonamide, 1 part of 20-50 μm chopped glass fiber, and 0.5 part of polyvinyl alcohol dispersant. Wherein, the parameters of the potassium albite feldspar are the same as those in the preparation example above.

[0137] 2) mix the clay, kaolin, potassium albite, expanded perlite powder, diopside, quartz sand, bentonite, fluorite powder and borax raw material powder components in the above proportions, and grind them with a grinder to obtain mixed raw material powder. After passing through ...

preparation example 3

[0145] Preparation of pre-foamed base ceramic blank 3

[0146] 1) choose raw material powder by following weight parts:

[0147] 50 parts of pottery clay, 30 parts of kaolin, 25 parts of potassium sodium feldspar, 20 parts of expanded perlite powder, 15 parts of diopside, 10 parts of quartz sand, 8 parts of bentonite, 3 parts of fluorite powder, silicon carbide and carbonic acid in equal weight ratio 4 parts of inorganic foaming agent composed of lithium, 2 parts of borax, 1 part of azodicarbonamide, 1 part of 30-50 μm chopped glass fiber, and 0.8 part of polyvinyl alcohol dispersant. Wherein, the potassium albite feldspar parameters are the same as above.

[0148] 2) mix the clay, kaolin, potassium albite, expanded perlite powder, diopside, quartz sand, bentonite, fluorite powder and borax raw material powder components in the above proportions, and grind them with a grinder to obtain mixed raw material powder. After passing through a 300-mesh sieve, add a glass fiber tough...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com