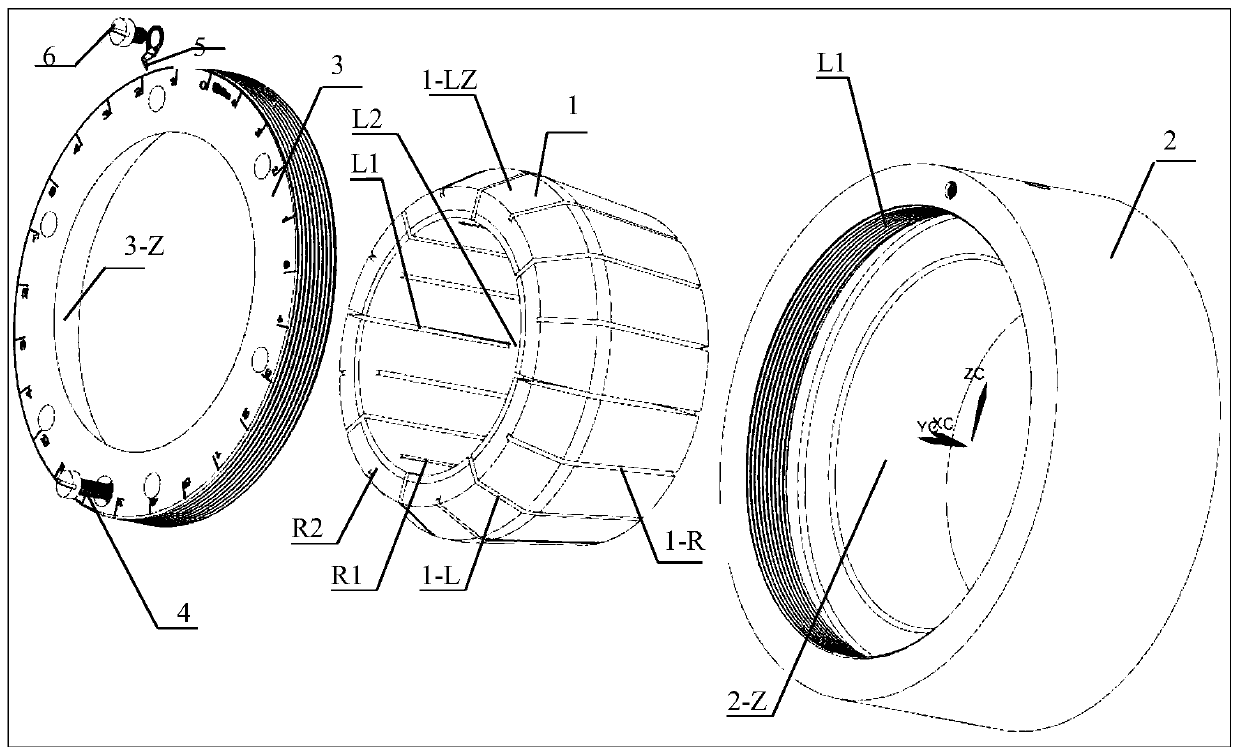

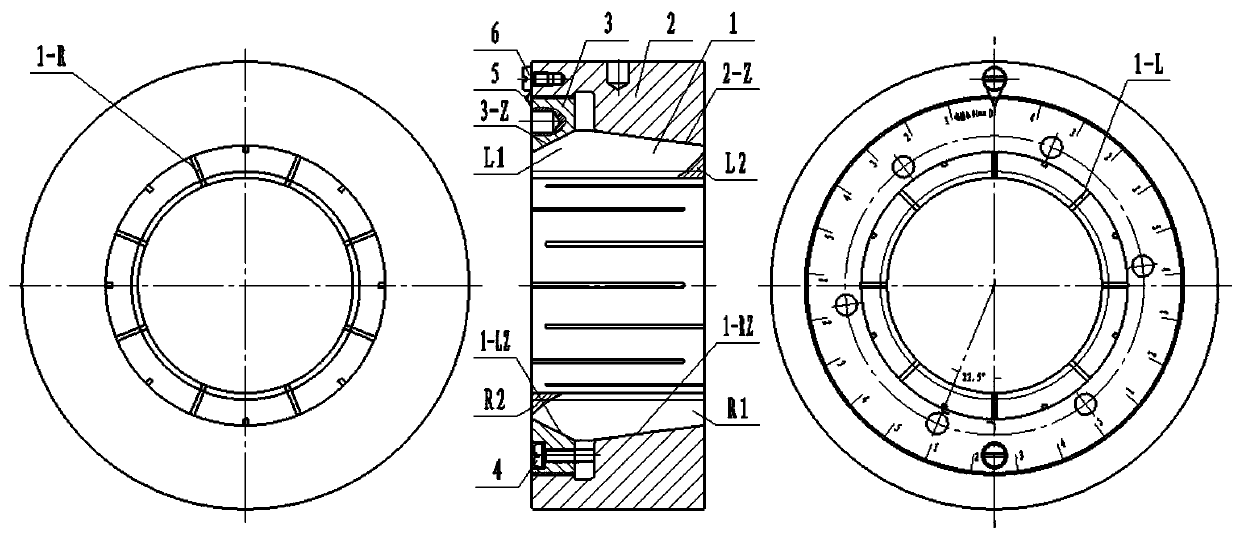

Elastic radial sliding bearing with adjustable gaps

An elastic bearing and radial sliding technology, applied in the direction of sliding contact bearings, bearings, bearing components, etc., can solve the problem of large clearance between the bearing and the rotor, and achieve the effect of large elastic scaling gap, serialization and standardization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] When assembling the sliding bearing of a gearbox, it was detected that the gap between the inner hole of the bearing and the rotor (transmission shaft) was 0.17mm. During the test run, it was found that the vibration of the shaft was relatively large. According to expert review and analysis, the gap between the bearing and the rotor (transmission shaft) was large and should be adjusted to 0.12mm. First, open the box, withdraw the A screw 4, turn the bearing inner sleeve 3 clockwise with the installation wrench, observe the scale pointer 5 moves counterclockwise from 0 scale to 5 scale (that is, move 5 grids), and then tighten the A screw 4 That is, use a dial indicator to recheck the actual clearance between the inner hole of the bearing and the rotor (drive shaft).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com