Novel LED packaging method

A technology of LED packaging and LED chips, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as cross excitation of phosphors, and achieve the effect of improving visual performance and material light energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

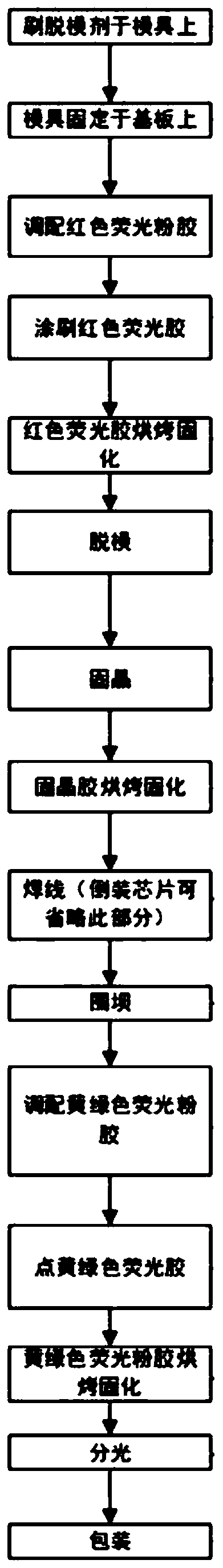

[0040] A new LED packaging method, such as figure 1 shown, including the following steps:

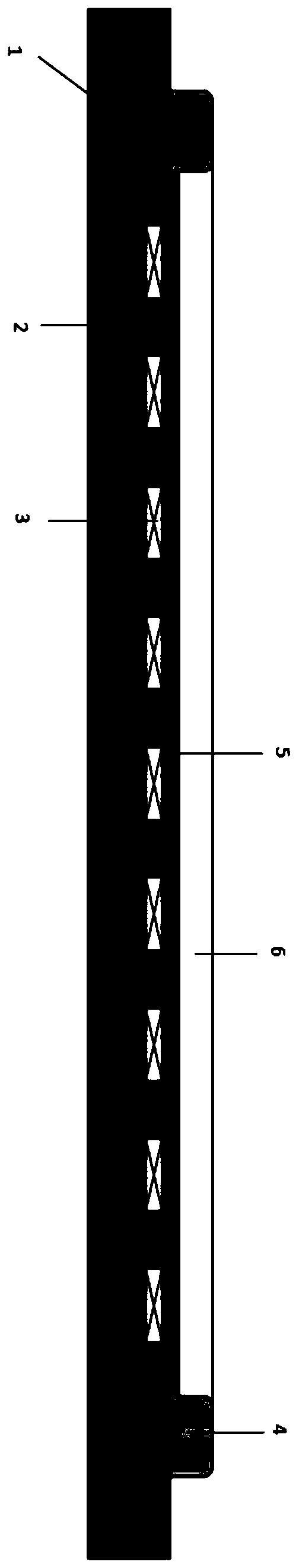

[0041] 1) Brush the release agent on the mold: use the release agent to evenly brush the edge of the mold hole and the contact surface with the substrate 1;

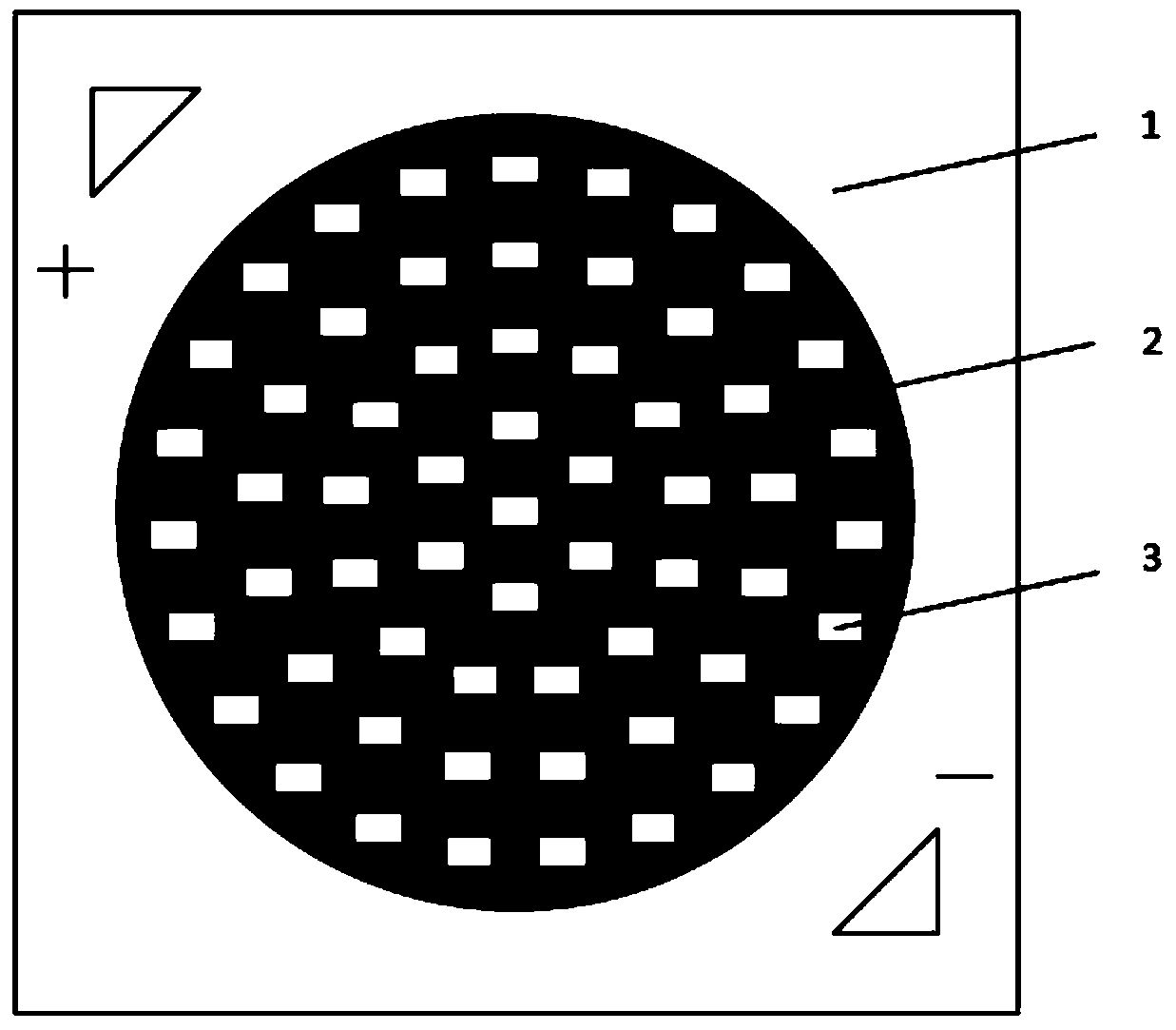

[0042] 2) The mold is fixed on the substrate 1: fix the mold that has been brushed with release agent according to the positioning hole of the substrate;

[0043] 3) Preparation of red phosphor glue 2: Evenly mix the proportioned silica gel and red phosphor, and vacuum stir to defoam after mixing. The mixing ratio of silica gel and red phosphor is 0.7:0.3; the wavelength of red phosphor is 619nm; the viscosity of silica gel is 26000mPas;

[0044] 4) Brushing the red phosphor glue 2: brush the red phosphor glue 2 obtained in step 3) into the mold hole in step 2) evenly;

[0045] 5) Red phosphor glue 2 is baked and cured: put the product that has completed step 4) into an oven at 150°C and bake for 1 hour to cure the red phosphor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com