Solar steam thermoelectric system

A solar steam and thermoelectric system technology, applied in solar thermal power generation, use of solar energy to generate mechanical power, machines/engines, etc., can solve the problems of high power generation cost, low photovoltaic power conversion efficiency, pollution, etc., and achieve high light energy conversion efficiency. , Improve the efficiency of light energy conversion, the effect of high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

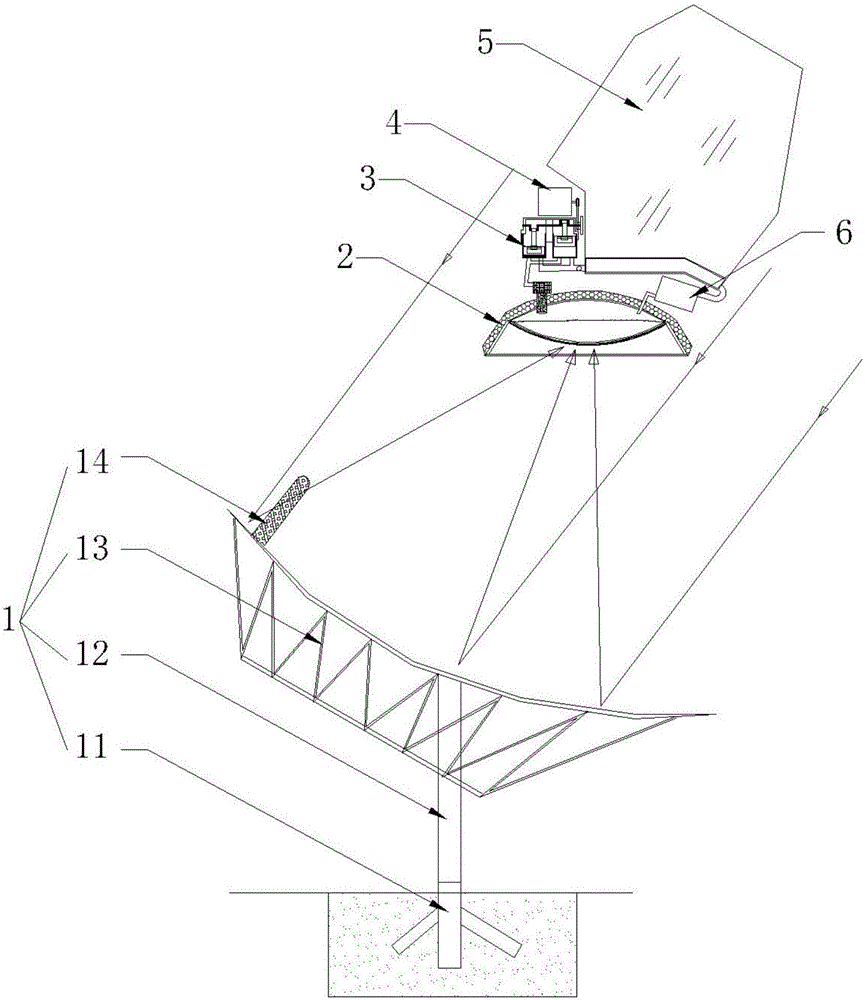

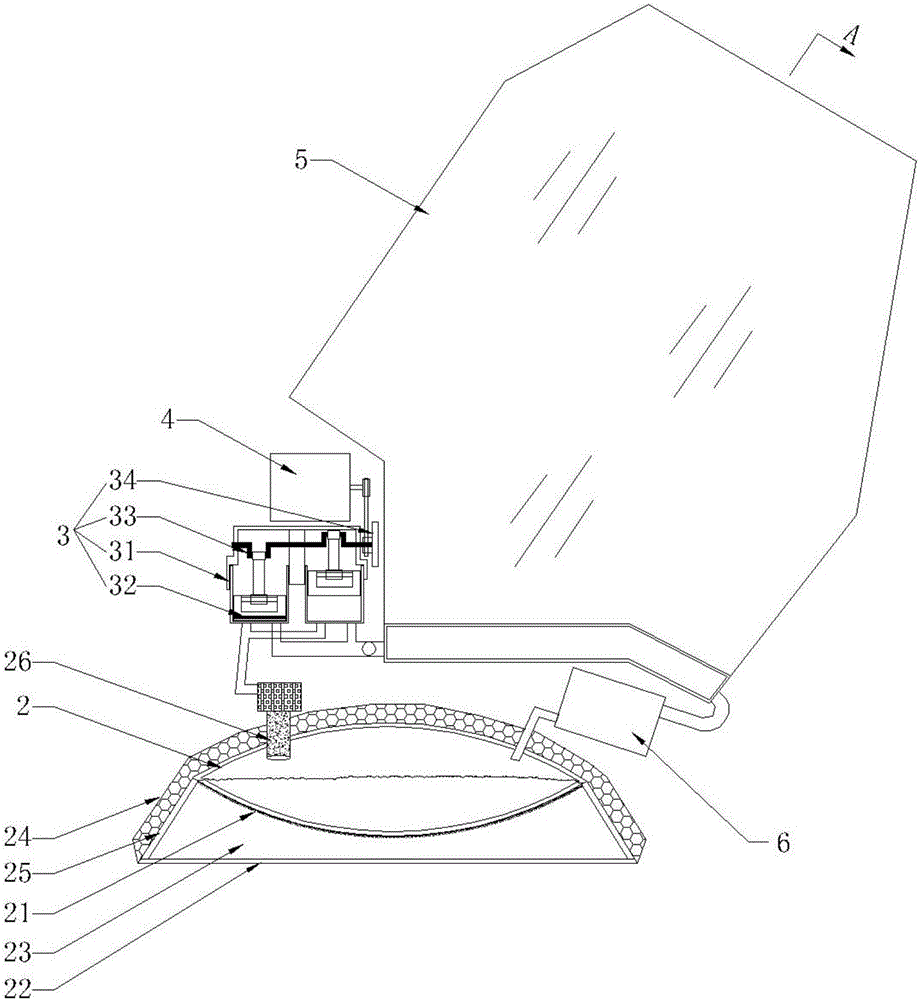

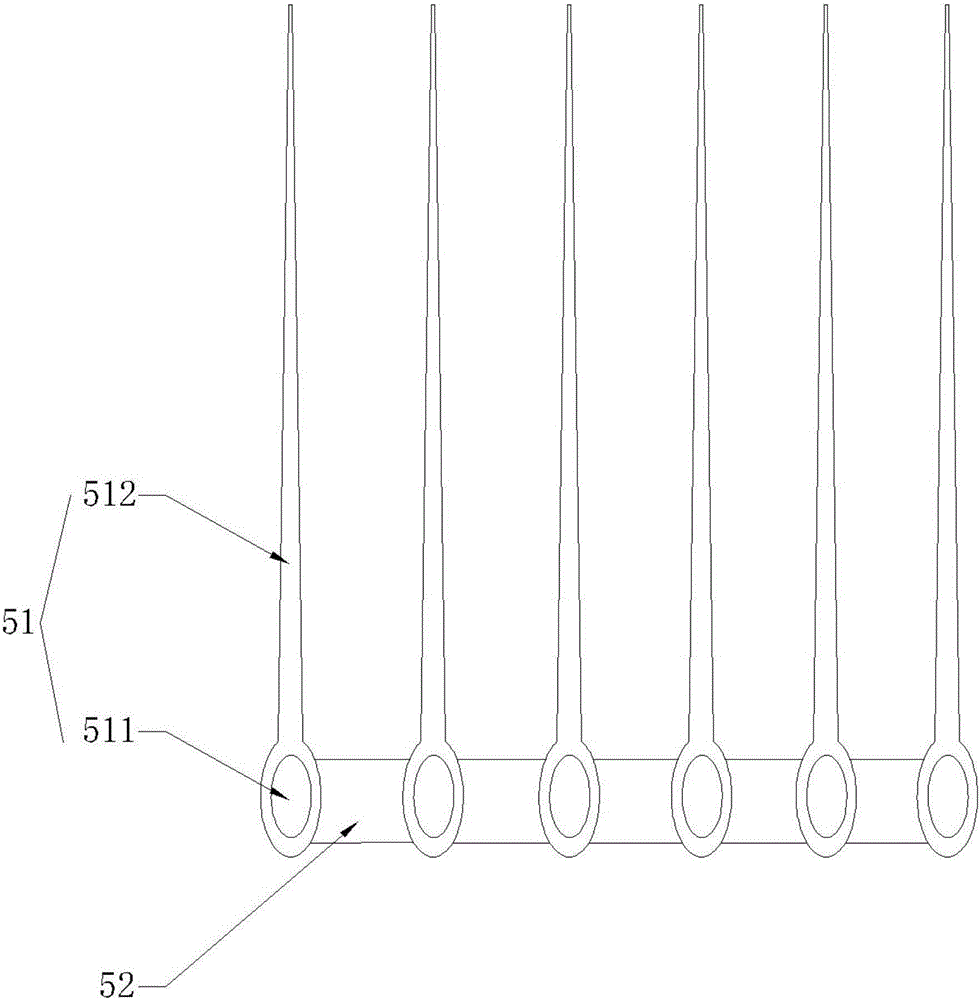

[0063] figure 1 A schematic structural view of the first embodiment of the solar steam thermoelectric system provided by the present invention; figure 2 for figure 1 A partial enlarged view of the solar steam thermoelectric system shown; image 3 for figure 2 The sectional view of the steam cooling device of the shown solar steam thermoelectric system in the direction A; Figure 4 for figure 2 Schematic diagram of the structure of the steam cooling device of the solar steam thermal power system shown.

[0064] Such as figure 1 with figure 2 As shown, the present embodiment provides a solar steam thermoelectric system, comprising:

[0065] A solar energy collection component 1 for collecting solar energy and increasing its energy density;

[0066] A high-pressure hot water boiler 2 for processing liquid water into high-pressure water vapor, and the high-pressure hot water boiler 2 is located at the energy output end of the solar energy collection component 1;

[00...

Embodiment 2

[0087] Figure 5 A partial structural schematic diagram of the second embodiment of the solar steam thermoelectric system provided by the present invention; Image 6 for Figure 5 The sectional view of the steam cooling device of the solar steam thermal power system shown in the B direction; Figure 7 for Figure 5 Schematic diagram of the structure of the steam cooling device of the solar steam thermal power system shown.

[0088] Such as Figure 5-7 As shown, the difference between the solar steam thermal power system provided in this embodiment and the first embodiment lies in the steam cooling device 5 . In this implementation, the steam heat dissipation device 5 includes a cylinder body, a heat dissipation coil 55 and a heat dissipation fan 56; , the other end is connected with the high-temperature water pressure return device 6, and the cooling fin 51 can also be connected on the cooling coil 55;

[0089]After the high-pressure water vapor has done work, it is inpu...

Embodiment 3

[0093] Figure 8 A schematic structural view of the third embodiment of the solar steam thermoelectric system provided by the present invention; Figure 9 for Figure 8 Schematic diagram of the structure of the steam cooling device of the solar steam thermal power system shown.

[0094] Such as Figure 8 with 9 As shown, the difference between the solar steam thermal power system provided in this embodiment and the first and second embodiments lies in the steam cooling device.

[0095] In this implementation, the steam cooling device includes a heat exchange coil 57, a steam pipe 58, a water pump 59 and a flow rate controller; The outer tubes of the exchange coil 57 are wrapped by an insulating layer to reduce heat loss, and the entire heat exchange coil 57 is tightly wrapped with an insulating material; One end is connected with the high-temperature water pressure return device 6; the outer wall of the outer tube of the heat exchange coil 57 is provided with a water inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com