Photosensitive chip packaging part and manufacturing method thereof

A technology for photosensitive chips and manufacturing methods, which is applied in the manufacture of electrical components, semiconductor devices, and final products, and can solve problems such as the inability to realize photosensitive characteristics of chips, improve stability and production efficiency, realize photosensitive characteristics, and reduce process difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

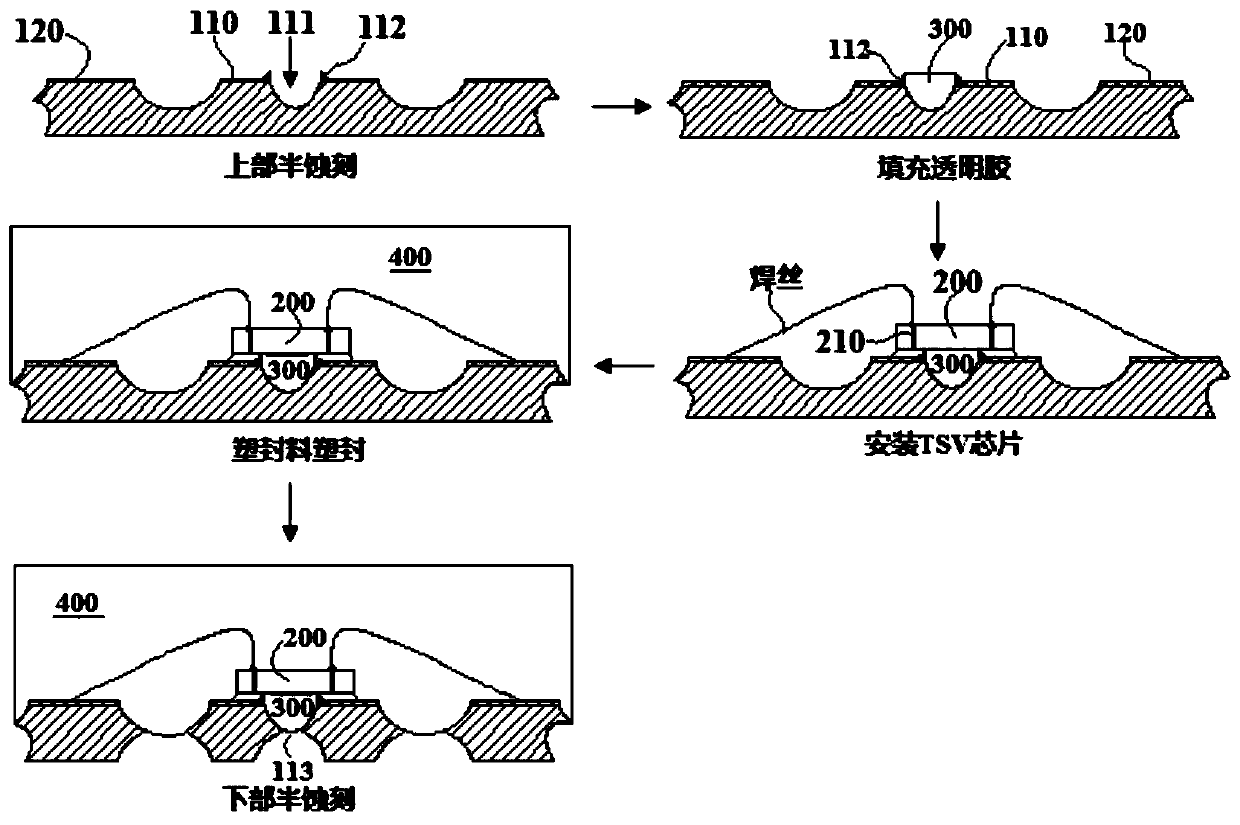

[0031] combine figure 1 Shown, the manufacture method of a kind of photosensitive chip package of the present invention, the method concrete steps of the present invention are as follows:

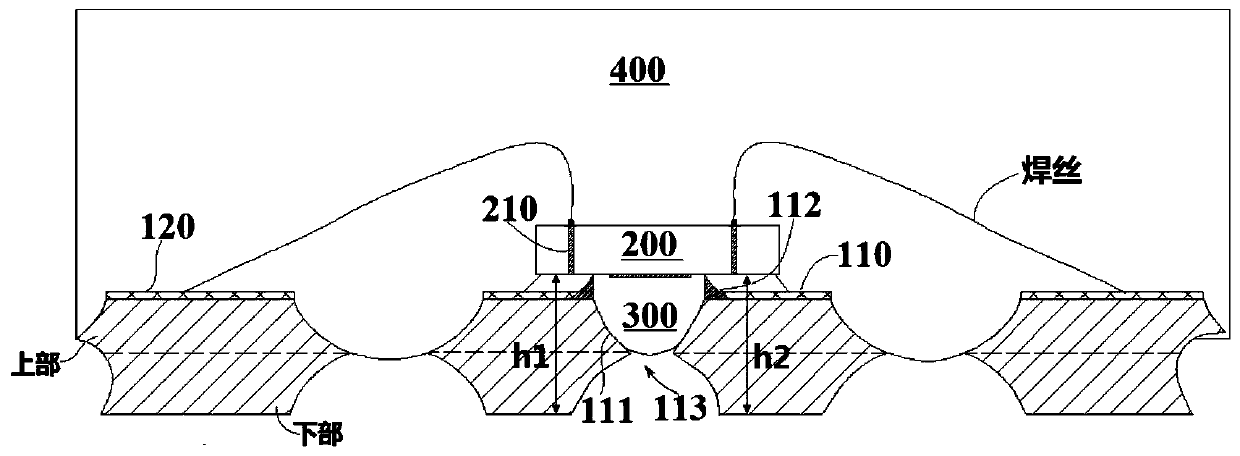

[0032] S1. Half-etch the upper part of the substrate to form the upper part of the base island 110 and the upper part of the pins 120 located on both sides or around the base island 110; then process the upper part of the base island 110 to obtain grooves 111 and dams 112 ; Specifically, the upper part of the base island 110 is stamped to form the groove 111 and the dam 112; it is worth noting that the dam 112 is extruded from a ductile metal substrate, specifically, during the stamping process, The metal material on the surface of the base island 110 is extruded to form a groove 111 inside the base island 110, while the metal material extends upward along the inner sidewall of the groove 111 to form a dam 112, and connects the dam 112 to the groove 111 , the groove 111 formed by stamping ...

Embodiment 2

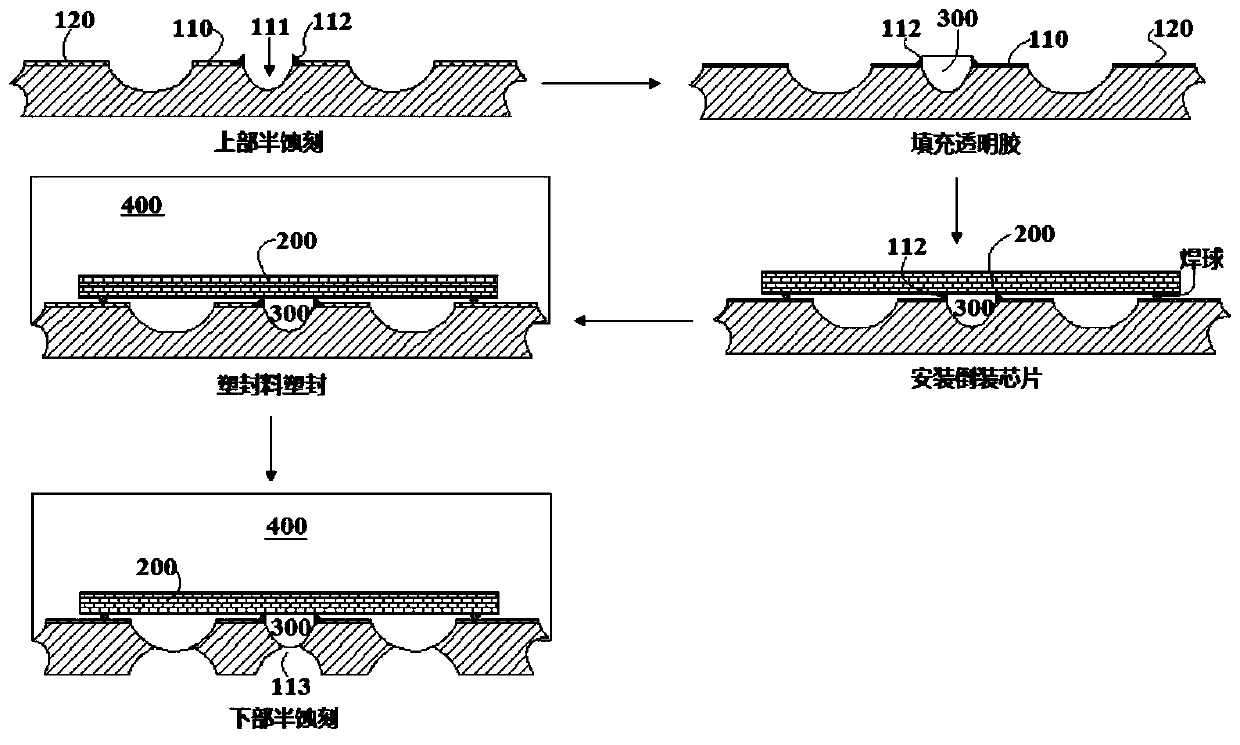

[0046] combine image 3 As shown, the content of this embodiment is basically the same as that of Embodiment 1, except that the chip 200 of this embodiment is flip-chip packaged, such as Figure 4 As shown, the chip 200 is electrically connected to the pin 120 through solder balls. In the method for manufacturing a photosensitive chip package of this embodiment, in step S3, solder balls are provided on both sides or around the bottom of the chip 200 in advance, the chip 200 provided with solder balls is placed on the transparent glue 300, and soldered The corresponding balls are electrically connected to the pins 120 , and the photosensitive area of the chip 200 is attached to the transparent adhesive 300 . Subsequently, the liquid transparent glue 300 is heated and cured. The dam 112 on the base island 110 can match the height of the solder balls, thereby raising the height of the transparent glue 300, so that the transparent glue 300 can be attached to the photosensitive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com