Valve

A solenoid and protective sleeve technology, applied in the field of valves, can solve problems such as errors, and achieve the effects of low cost, simple manufacturing, and reliable protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

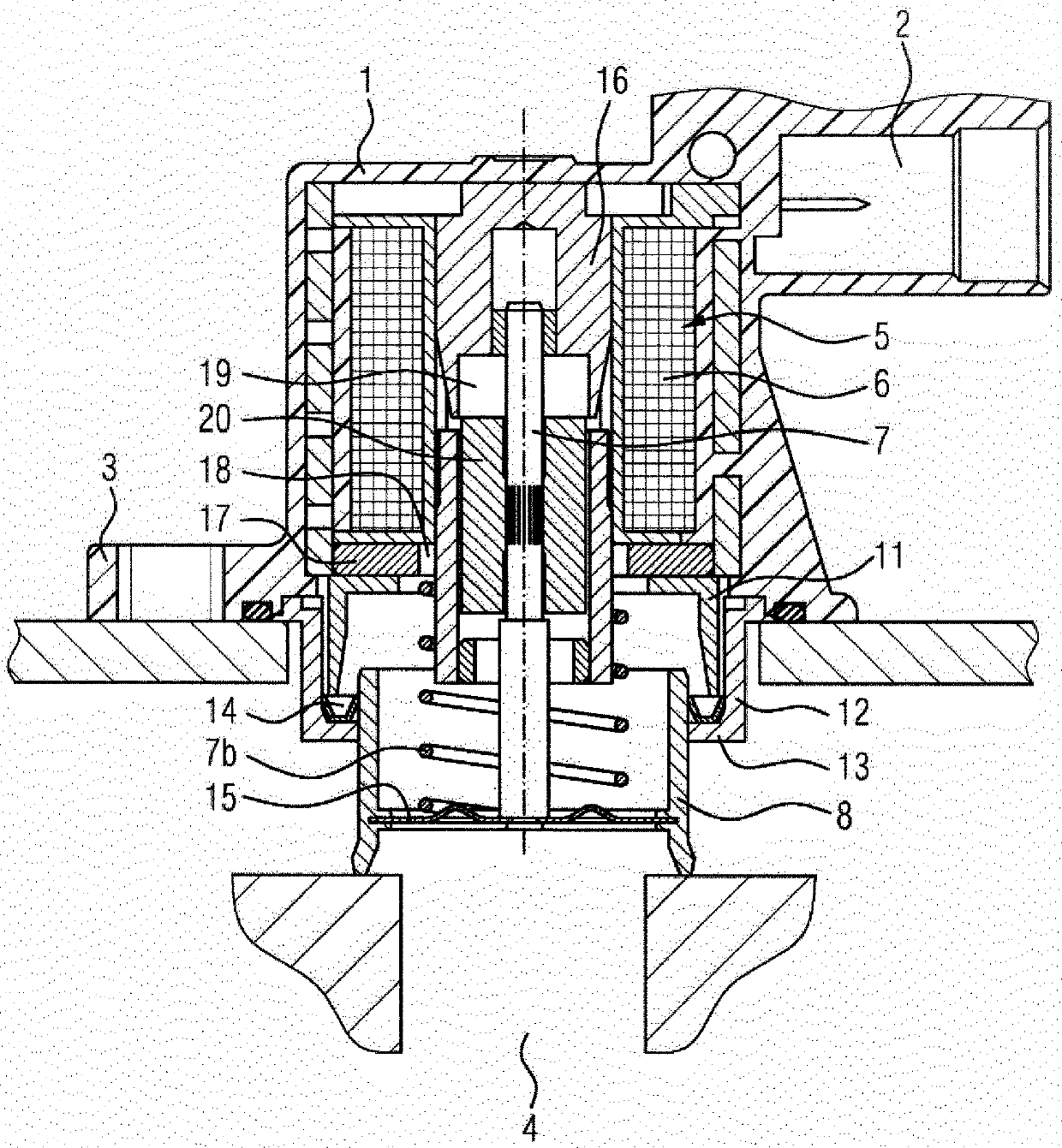

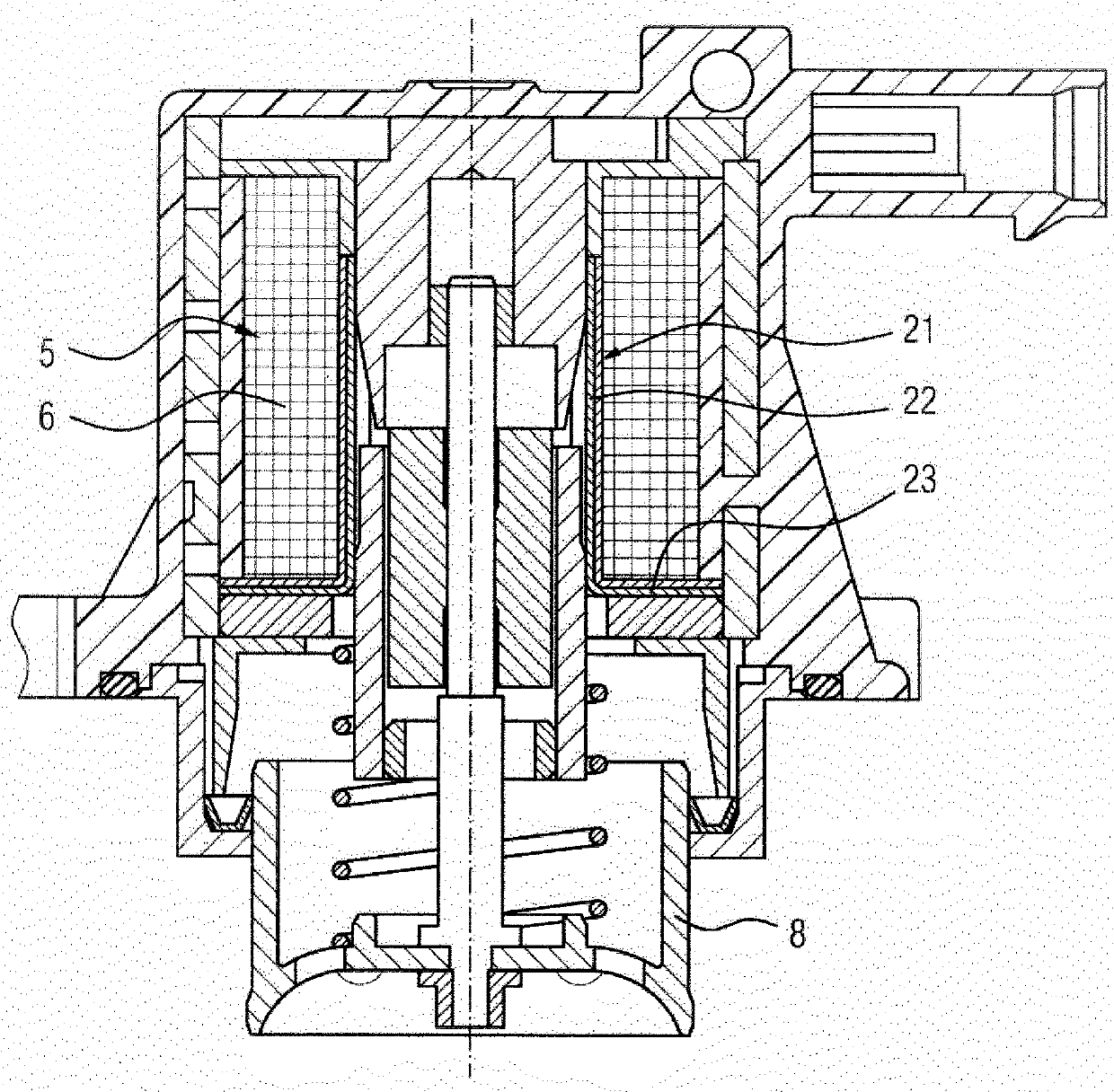

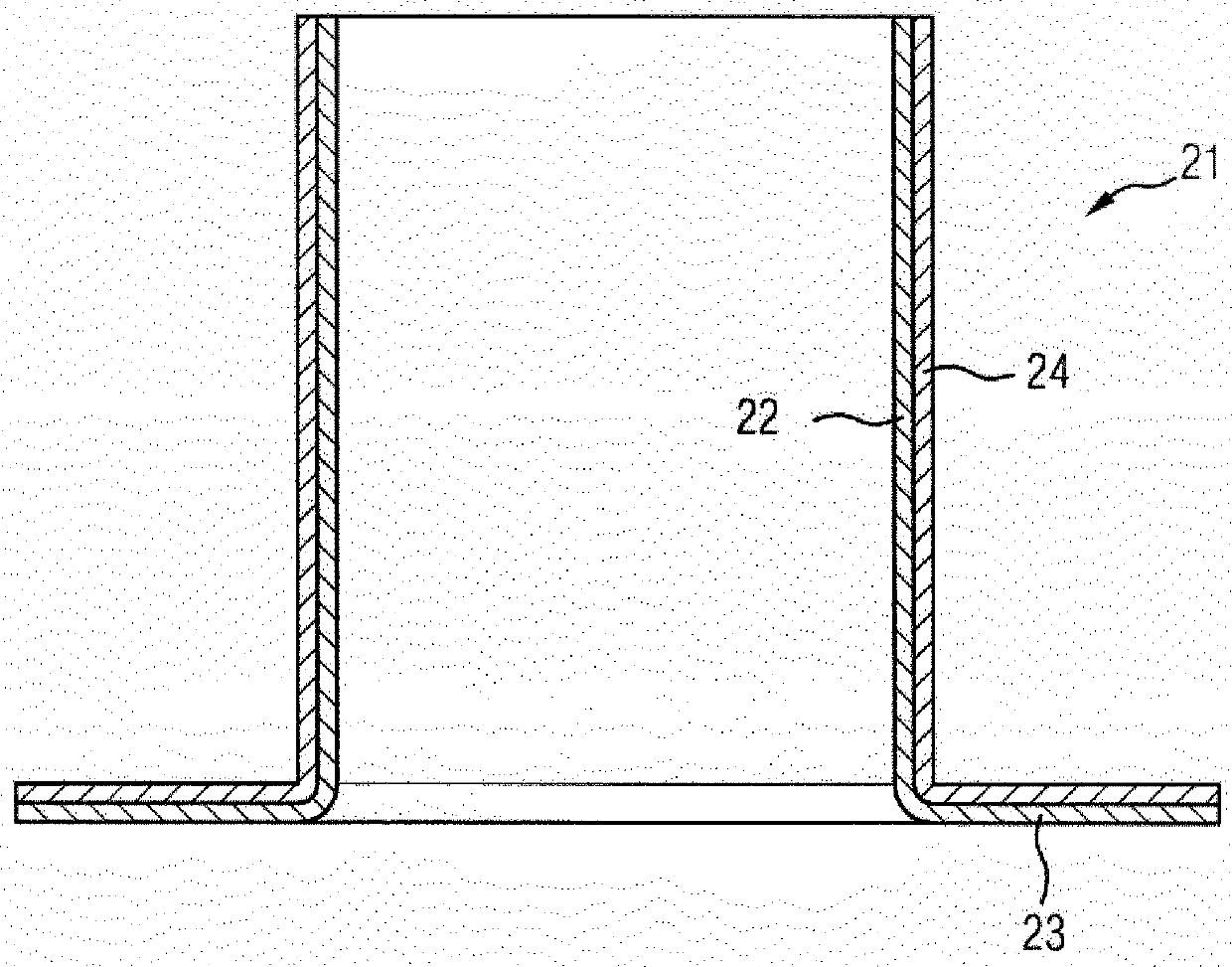

[0015] figure 1 The valve is shown, including the housing 1 . Furthermore, the housing 1 has an integrally formed flange 3 , via which the housing 1 is flanged to a turbocharger (not shown) in the region of the bypass line. The electrical contacting of the solenoid 5 , which is arranged in the housing 1 , takes place via the socket 2 . The solenoid 5 has a coil 6 which acts on a metal rod 7 . The metal rod 7 is connected to a pot-shaped piston 8 , which has a sealing surface 10 on the circumference of its lower part 9 , which cooperates with a valve seat (not shown). Here, the spring 7a pushes the piston 8 towards the valve seat. The housing 1 also has a cylindrical section 11 which extends in the direction of the piston 8 . A cylindrical bushing 12 connected to the housing surrounds the cylindrical section 11 . The cylindrical bush 12 has a radially inward flange 13 on which a seal 14 is placed. The seal 14 here seals the piston 8 relative to the housing 1 . The openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com