Dried meat floss processing technology convenient for packaging

A processing technology and technology of meat floss, applied in the field of meat floss processing technology, can solve the problems of inconvenient packaging, disorderly distribution of meat floss and floss, and achieve the effects of improving control, improving flexibility, and facilitating packaging and later transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

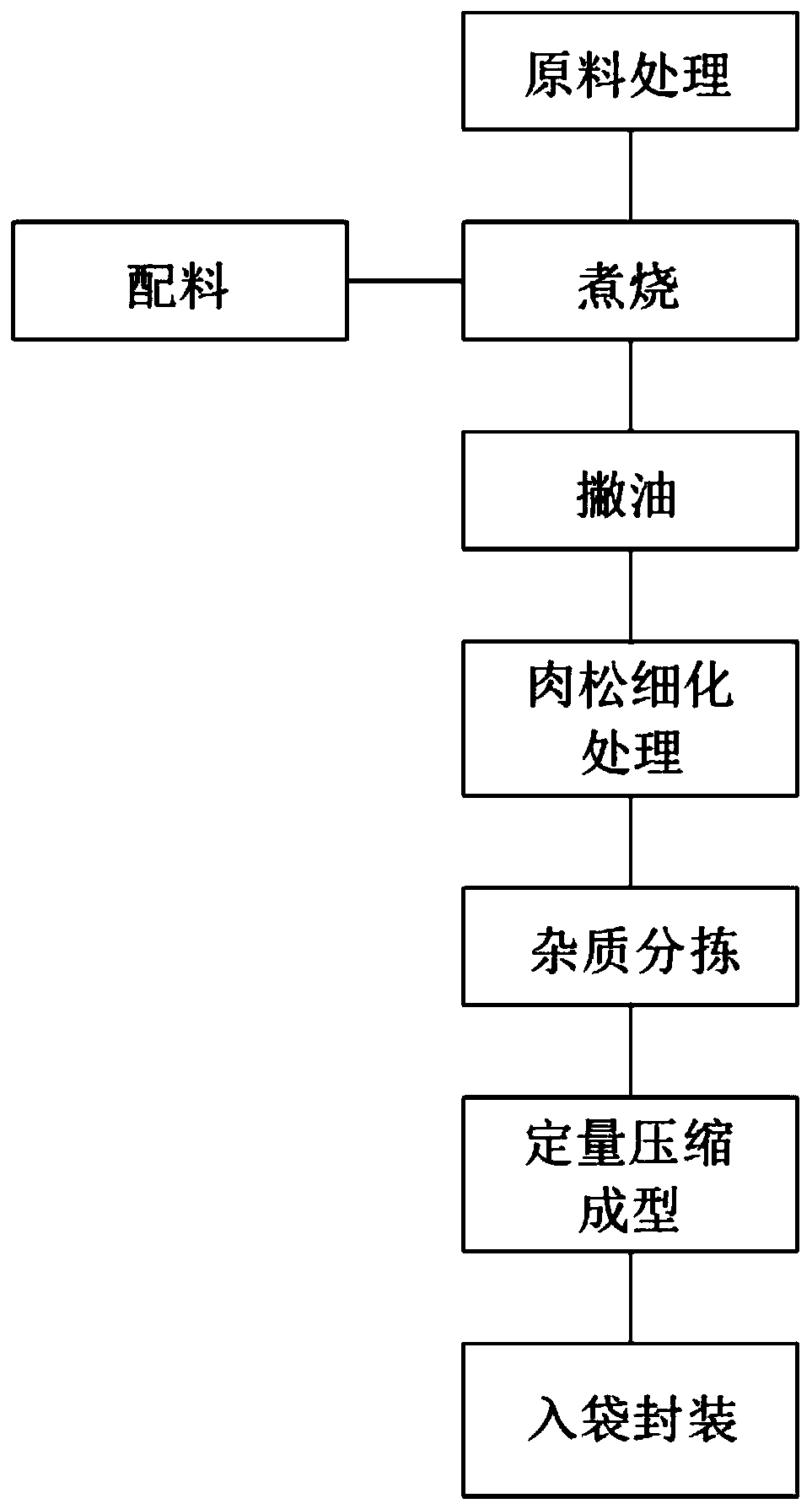

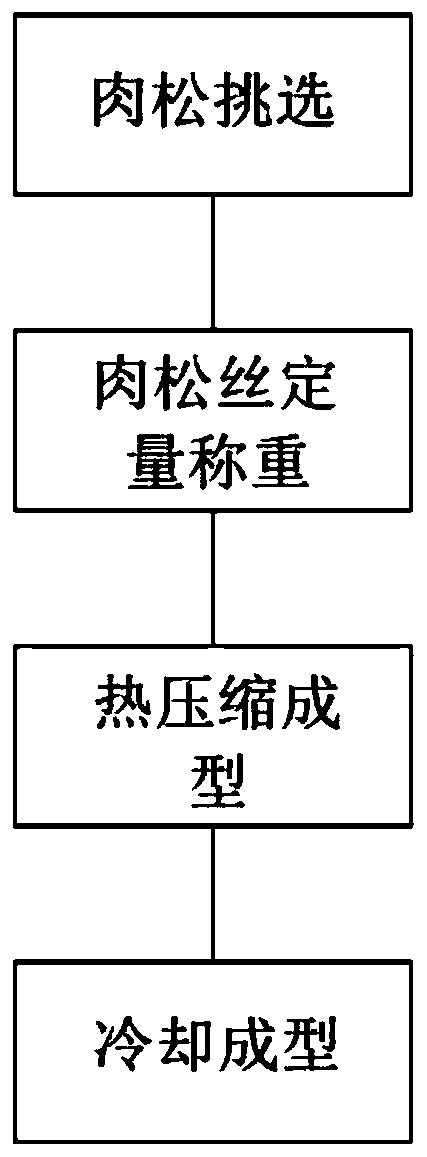

[0028] Please refer to figure 1 and figure 2 ,in, figure 1 A process flow diagram of a preferred embodiment of the dried meat floss processing technology that is conveniently packaged provided by the present invention;

[0029] figure 2 for figure 1 Process flow diagram of the quantitative compression molding part shown. A kind of meat floss processing technology that is convenient to carry out packaging comprises the following steps:

[0030] S1 Raw material processing: select pork front legs and back meat, wash and remove excess parts, wash and dry, and refrigerate for later use;

[0031] S2 ingredients: 6.5kg of white soy sauce, 6.5kg of red soy sauce, 1.5kg of refined salt, 10kg of white sugar, 250g of sorghum wine and 150g of monosodium glutamate;

[0032] S3 cooking: Put the spare pork prepared in S1 into a cooking pot, add 90kg of pork t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap