On-line surfacing repair method for weld repair of carbon steel branch pipe

A repair method and carbon steel technology, applied in welding equipment, welding accessories, arc welding equipment, etc., to improve the state and distribution, shorten the time of outage, and inhibit the initiation and expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

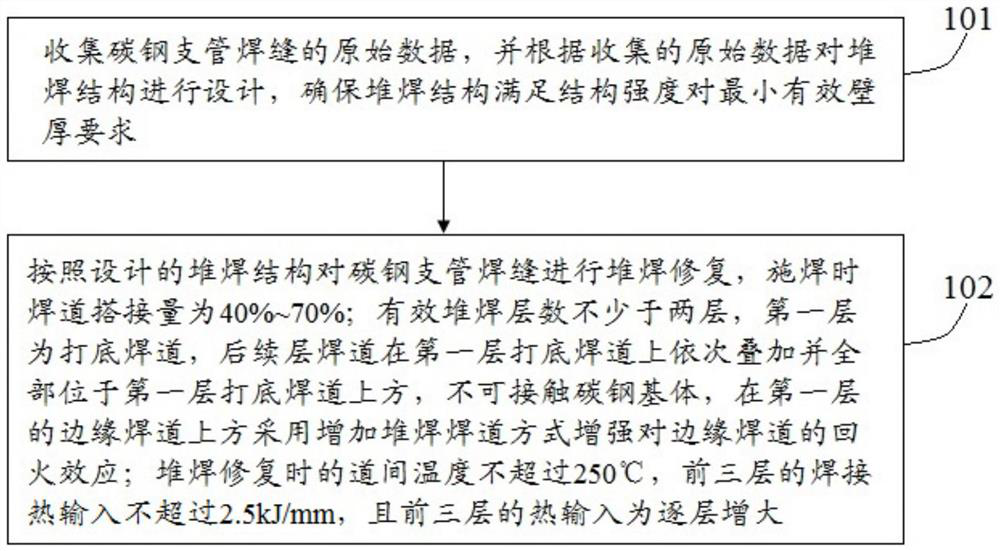

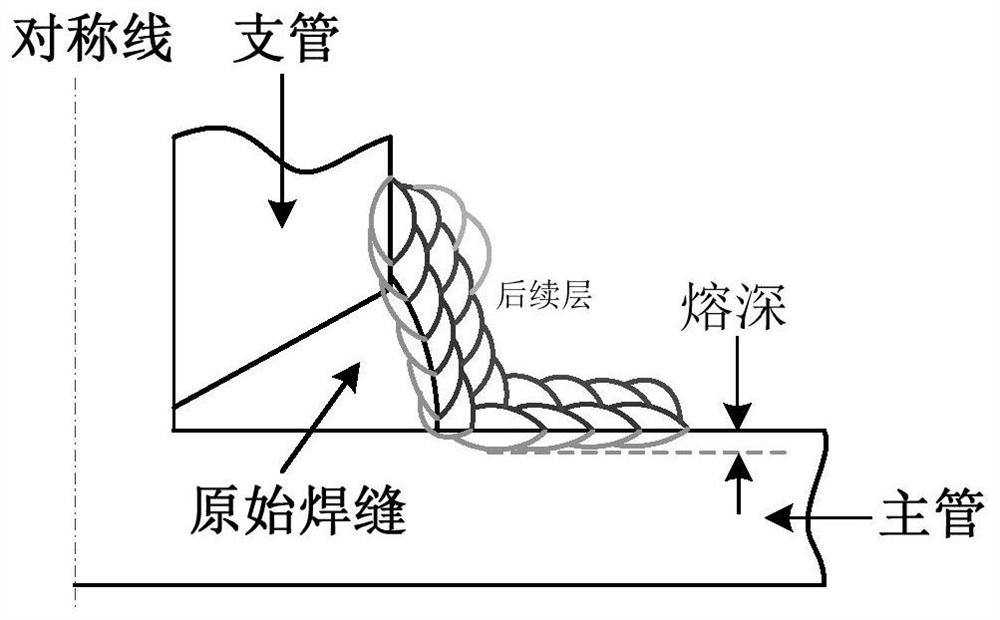

[0034] see figure 1 with figure 2 , the present invention is used for the on-line surfacing welding repair method of carbon steel branch pipe welding seam repair comprising the following steps:

[0035] Step 101, collect the original data of the carbon steel branch pipe weld, and design the surfacing structure according to the collected original data, to ensure that the surfacing structure meets the minimum effective wall thickness requirements for structural strength and structural integrity.

[0036] Specifically, the raw data of carbon steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com