Device for pretreating biomass fuel particles

A biomass fuel and pretreatment technology, applied in application, wood stamping, cutting equipment, etc., can solve the problems of reducing the number of layouts, easy wear of knives, and reducing the efficiency of biomass fuel crushing, so as to achieve the goal of improving versatility and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

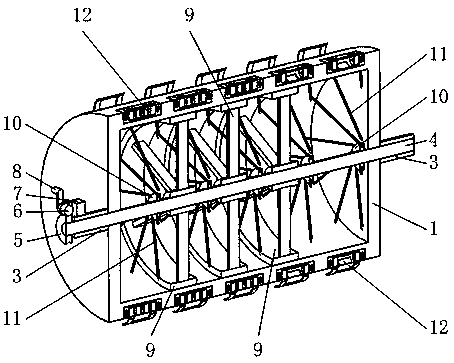

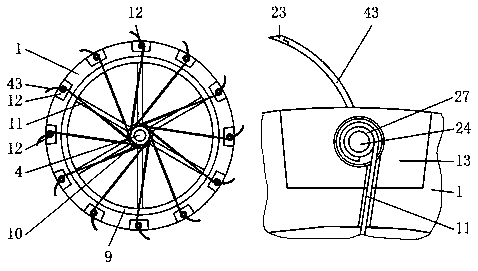

[0035] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

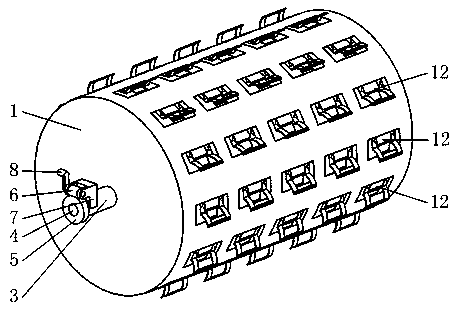

[0036] Such as figure 1 , 2 As shown, it includes a roller 1, a shaft sleeve 3, and a crushing module 12, among which figure 2 As shown, the hollow roller 1 rotates in the crushing equipment, and the two bushings 3 symmetrically installed at the center of both ends of the roller 1 are rotatably matched with the crushing equipment; figure 1 , 2 As shown in , 4, a number of installation grooves 2 evenly distributed on the outer cylindrical surface of the roller 1 are installed with a crushing module 12 for performing soft and hard classification and crushing of the biomass fuel entering the crushing equipment.

[0037] Such as Figure 5 , 8 As shown, the crushing module 12 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com