Polyester material friction welding module based on high-frequency vibration and geogrid

A friction welding, polyester material technology, applied in other home appliances, home appliances, applications, etc., to achieve the effect of reducing amplitude and increasing effective power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

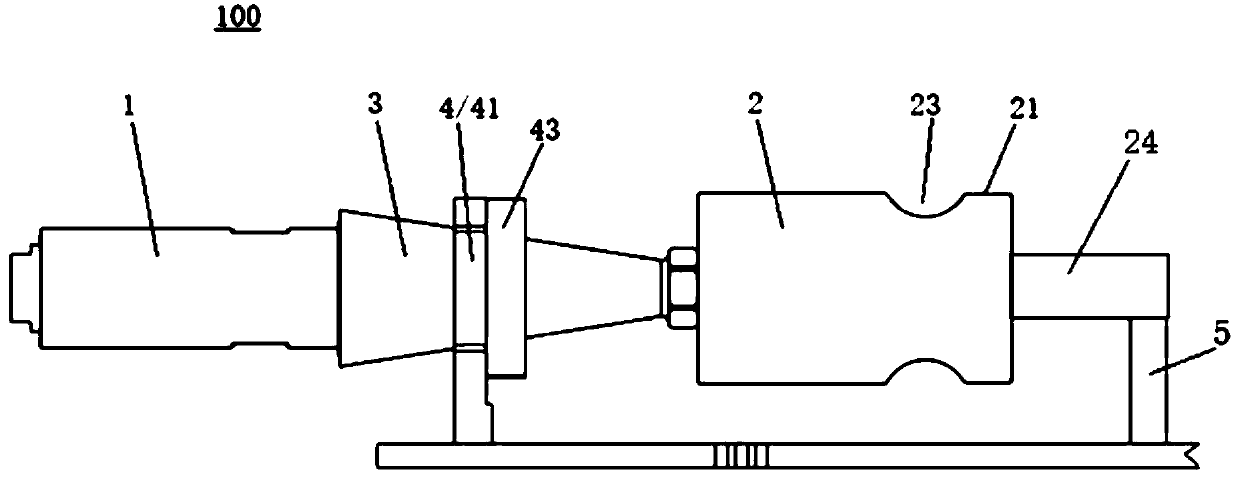

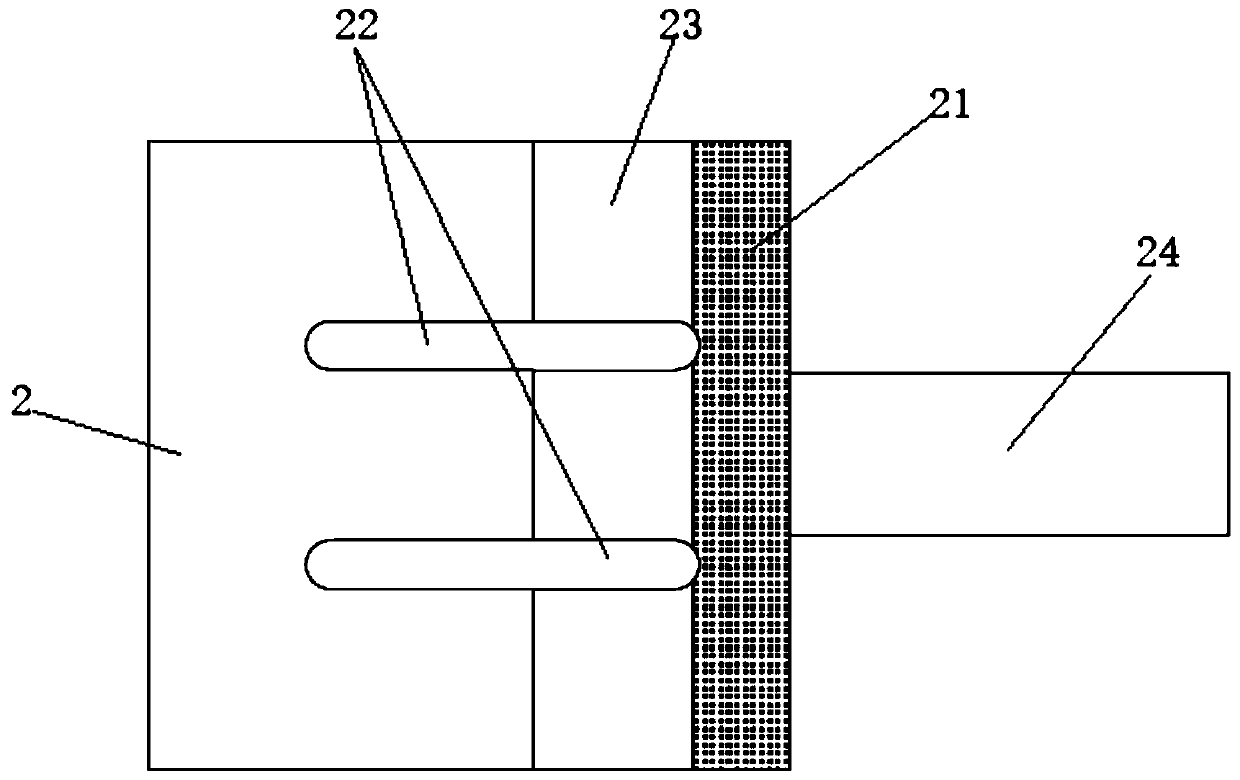

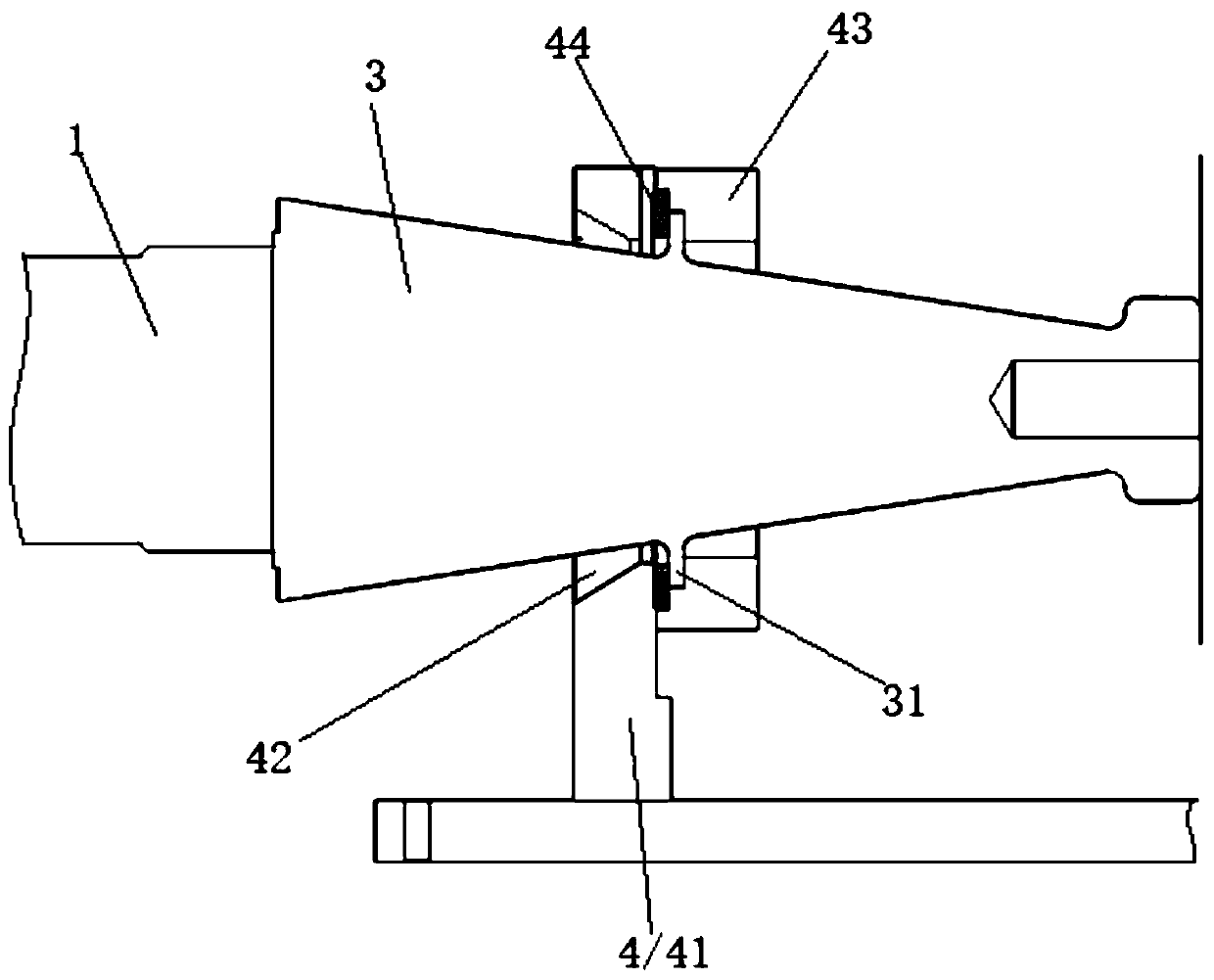

[0024] Please refer to Figure 1-Figure 3 , the present embodiment is a polyester material friction welding module 100 based on high-frequency vibration, which includes an ultrasonic generator (not shown in the figure) that converts 50-60 Hz electric energy into 15-40 kHz high-frequency electric energy, The high-frequency electric energy converted and output by the ultrasonic generator is converted into an ultrasonic transducer 1 of the same frequency mechanical motion, and the mechanical motion output by the ultrasonic transducer 1 is transmitted to an amplitude modulator 3 of a friction welding joint 2 after amplitude modulation. The outer end area of the upper surface of the welding head 2 is provided with a friction welding working surface 21, and the surface array of the friction welding working surface 21 is provided with several needle plate structures; The stress distribution groove 23.

[0025] The friction welding joint 2 is a three-dimensional block structure. T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap