Nonel detonator assembly line and production method

A technology for assembling production lines and detonating tubes, applied to detonators, offensive equipment, etc., can solve the problems of low production efficiency, manual operation, safety accidents, etc., achieve high production efficiency, convenient classification, and reduce safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

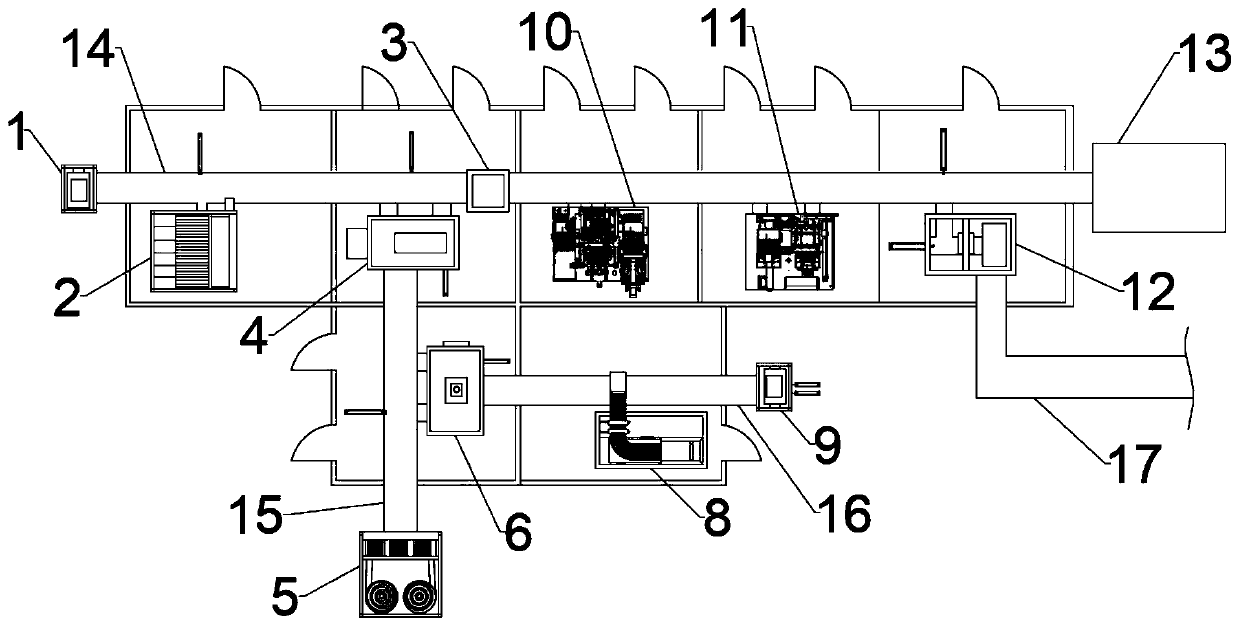

[0039] like Figure 1-Figure 3 As shown, this embodiment provides a nonel detonator assembly production line, including a detonator mold delivery device 1, a first conveying device 14, a basic detonator arrangement machine 2, an assembly machine 4, a detonator bayonet machine 10, and a detonator coding machine 11 , packing machine 12 and detonator mold recovery device 13, the output end of detonator mold throwing device 1 is connected with an end of the first conveying device 14, and wherein detonator mold throwing device 1 drops the detonator mold on the first conveying device 14, so that the first A conveying device 14 drives the detonator mold to move, and the other end of the first conveying device 14 is connected to the input end of the detonator mold recovery device 13, wherein the detonator mold recovery device 13 is used to recycle the detonator mold after use, and the basic detonator arrangement machine 2 , assembling machine 4, detonator bayonet machine 10, detonator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com