Anti-reflection and light orientation composite film and preparation method and application thereof

An anti-reflection film layer, anti-reflection technology, applied in the direction of film/sheet adhesives, coatings, adhesives, etc., can solve the problems of increasing cost, singleness, reducing the degree of freedom of ergonomic design, and achieving easy installation. and disassembly, reduce costs, and improve ergonomic design freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

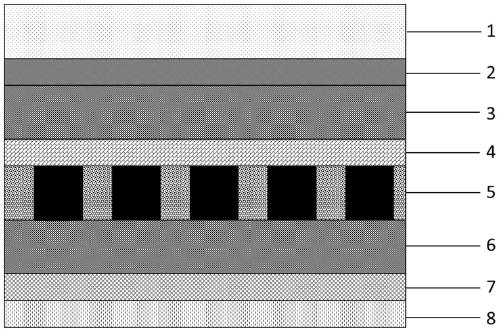

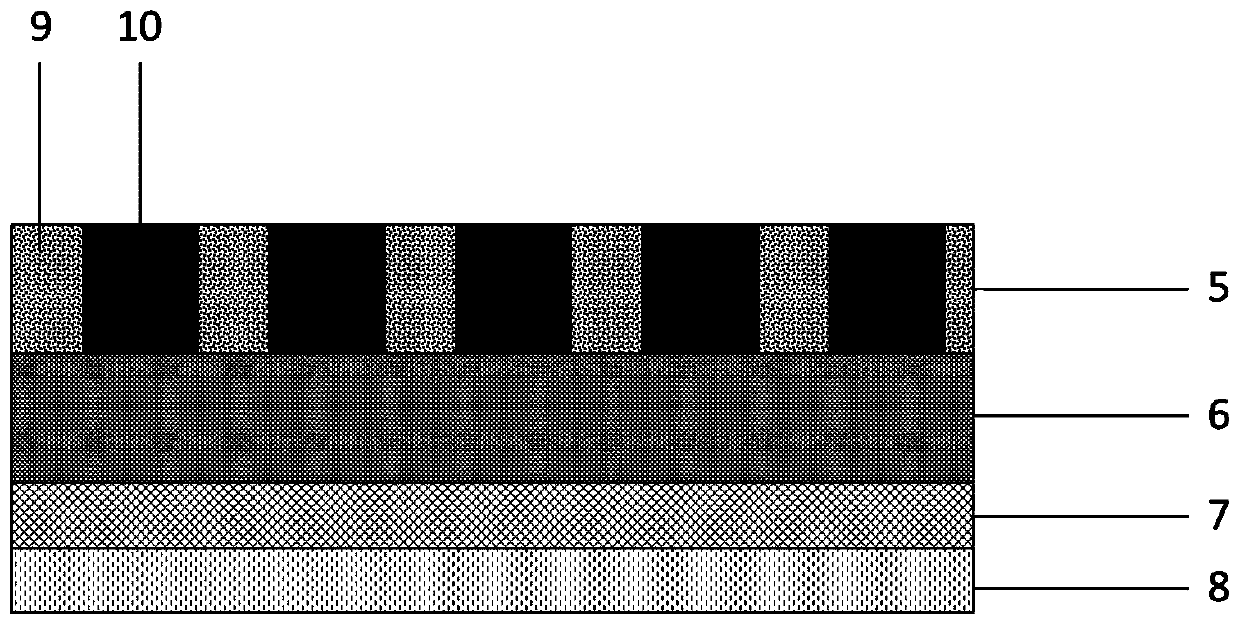

[0046] A method for preparing an antireflection and light orientation composite film disclosed by the present invention comprises the following steps:

[0047] Step 1), adding each component in the coating liquid formula of the transparent coating 9 into the container according to its corresponding weight fraction and stirring to obtain the coating liquid of the transparent coating 9, and coating the coating liquid of the transparent coating 9 On one side of the first transparent support 6, it is cured by ultraviolet light, and then strip-shaped grooves or grid-shaped grooves are pressed out by precision micro-replication engraving rollers to form the transparent coating 9 area; the coating of the light-absorbing coating 10 Each component in the liquid formula is added to the container according to its corresponding weight fraction and stirred to obtain the coating liquid of the light-absorbing coating 10, and the coating liquid of the light-absorbing coating 10 is coated in th...

Embodiment 1

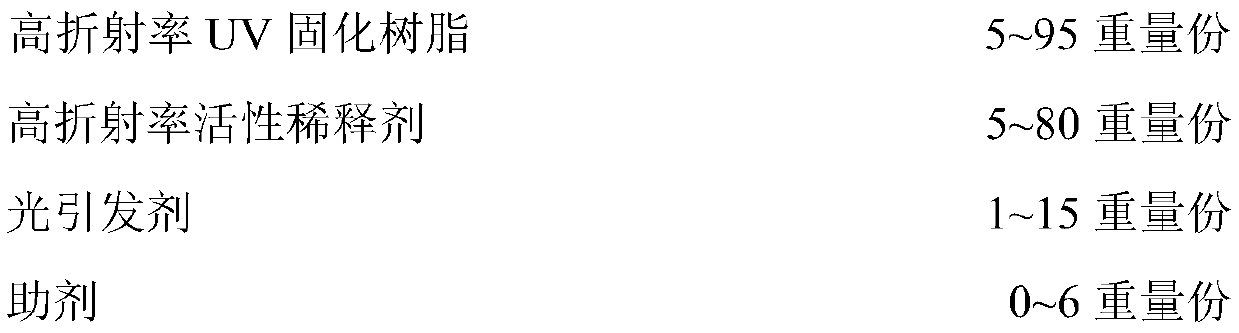

[0061] The various raw materials in the transparent coating are weighed according to the following proportions, and mixed and stirred to make them uniform:

[0062]

[0063] The various raw materials in the light-absorbing coating are weighed according to the following proportions, and mixed and stirred to make them uniform:

[0064]

[0065] The various raw materials in the anti-reflective hard coating are weighed according to the following proportions, and mixed and stirred to make them uniform:

[0066]

[0067]

[0068] Using precision coating composite equipment, in a thousand-class clean environment, the coating solution of the transparent coating 9 is coated on one side of the first transparent support 6, cured by ultraviolet light, and then pressed out by a precision micro-replication engraving roller Shaped grooves or grid-shaped grooves form the transparent coating 9 areas; the coating liquid of the light-absorbing coating 10 is applied to the strip-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com