Polyurea type reflective heat-insulation aerogel transparent glass coating and preparation method thereof

A technology of transparent glass and airgel, applied in reflection/signal coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of reducing transparency and heat insulation performance, low light transmittance of film-attached heat insulation materials, equipment and equipment Big investment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

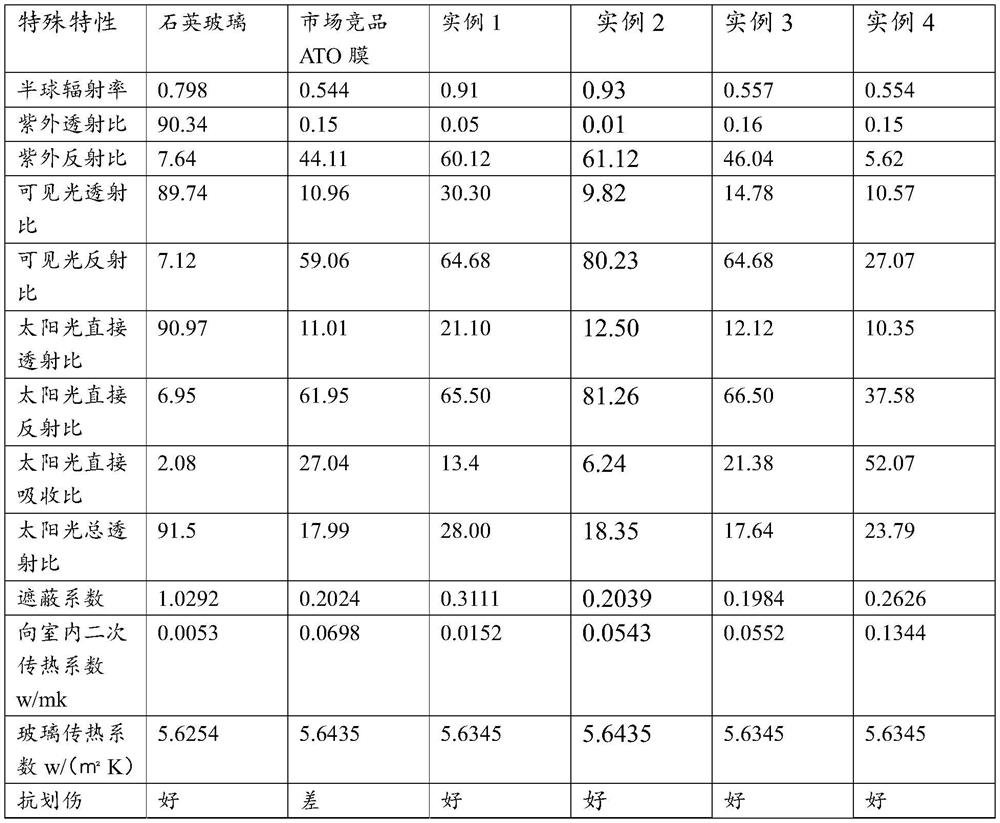

Examples

Embodiment 1

[0059] This embodiment provides a polyurea-type reflective heat-insulating airgel transparent glass coating, which is prepared by the following preparation method:

[0060] S1: Slowly add 1.25g of nano-zinc carbonate powder and 5g of water glass into 10g of stannous acetate ethanol solution with a mass concentration of 2.368% under stirring, and stir to disperse evenly;

[0061] S2: Add 1.7g of hydrogen peroxide with a mass concentration of 1%. After no gas overflows, filter and wash the filtered gel with pure water. The clean standard is to use silver nitrate titration to obtain perovskite without visual precipitation. Structured zinc tin oxide and silica composite gel;

[0062] S3: Dissolving urea in pure water to obtain a urea solution, and at 20°C, the mass concentration of the urea solution is 5.71%; meanwhile, mix the perovskite structure zinc tin oxide and silicon dioxide obtained in step S2 with stirring The composite gel is mixed with the urea solution and stirred ev...

Embodiment 2

[0071] This embodiment provides a polyurea-type reflective heat-insulating airgel transparent glass coating, which is prepared by the following preparation method:

[0072] S1: Slowly add 12.5g of nano-zinc carbonate powder and 50g of water glass into 100g of stannous acetate ethanol solution with a mass concentration of 12.5% under stirring, and stir to disperse evenly;

[0073] S2: Add 17g of hydrogen peroxide with a mass concentration of 5%. After no gas overflows, filter and clean the filtered gel with pure water. The standard for cleaning is to use silver nitrate titration to obtain a perovskite structure without visual precipitation. Composite gel of zinc tin oxide and silicon dioxide;

[0074] S3: Dissolving urea in pure water to obtain a urea solution, and at 20°C, the mass concentration of the urea solution is 25%; meanwhile, mix the perovskite structure zinc tin oxide and silicon dioxide obtained in step S2 under stirring The composite gel is mixed with the urea s...

Embodiment 3

[0083] This embodiment provides a polyurea-type reflective heat-insulating airgel transparent glass coating, which is prepared by the following preparation method:

[0084] S1: Slowly add 125g of nano-zinc carbonate powder and 50g of water glass into 100g of stannous acetate ethanol solution with a mass concentration of 23.68% under stirring, and stir to disperse evenly;

[0085] S2: Add 170g of hydrogen peroxide with a mass concentration of 10%. After no gas overflows, filter and wash the filtered gel with pure water. The standard for cleaning is to use silver nitrate titration to obtain a perovskite structure without visual precipitation. Composite gel of zinc tin oxide and silicon dioxide;

[0086] S3: Dissolving urea in pure water to obtain a urea solution, and at 20°C, the mass concentration of the urea solution is 57.1%; meanwhile, mix the perovskite structure zinc tin oxide and silicon dioxide obtained in step S2 with stirring The composite gel is mixed with the urea s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com