Hydraulic cylinder

A technology of hydraulic cylinders and cylinder blocks, applied in the field of hydraulic cylinders, can solve the problems of increased processing difficulty, poor buffering effect, uncontrollability, etc., and achieve the effects of reducing processing and matching accuracy requirements, facilitating processing and manufacturing, and improving motion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

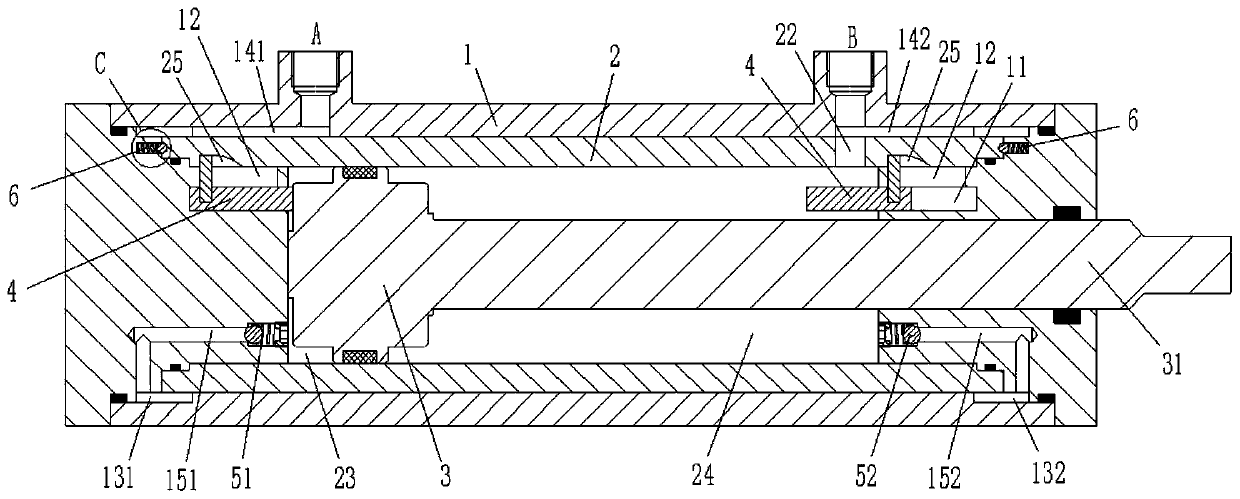

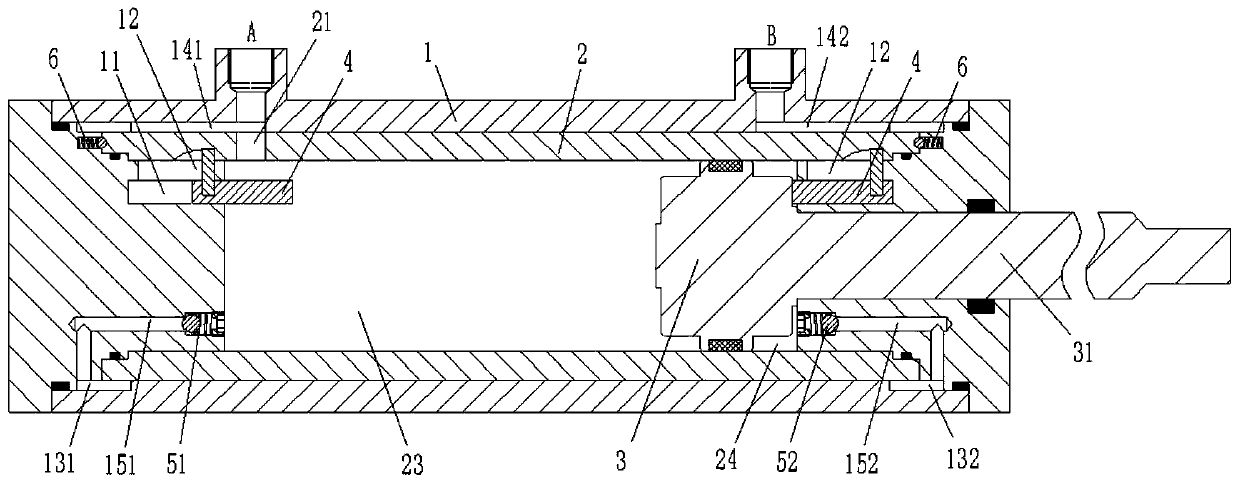

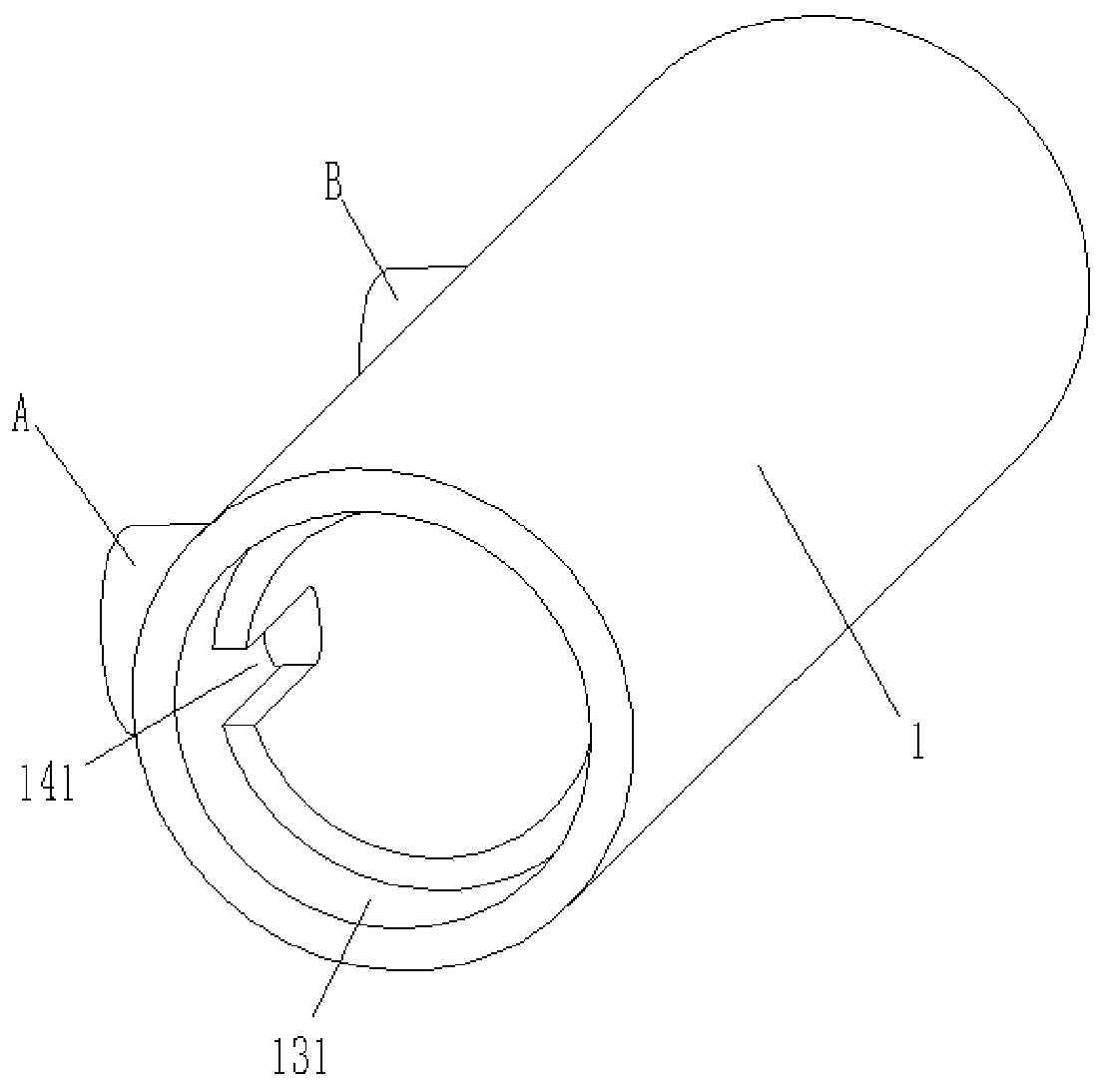

[0028] combine Figure 1 to Figure 5 As shown, the hydraulic cylinder of this embodiment includes a cylinder body 1 , a cylinder barrel 2 and a piston 3 . Wherein, the cylinder body 1 is provided with an A port and a B port, and the cylinder body 2 is provided with a first through hole 21 and a second through hole 22, and the cylinder body 2 can reciprocate relative to the cylinder body 1 inside the cylinder body 1 turn. The piston 3 is located inside the cylinder 2 and divides the inside of the cylinder 2 into a first control chamber 23 and a second control chamber 24 which are not connected to each other. A piston rod 31 is provided at one end of the piston 3 , and the piston rod 31 protrudes to the outside of the cylinder body 1 through the first control cavity 23 . The first control chamber 23 communicates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com