Rock creep test method and device under action of multiple environments

A creep test and multi-environment technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of less research on creep experiments, energy consumption, time consumption, etc., and achieve low instrument prices and high safety factors , The effect of simple operation of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

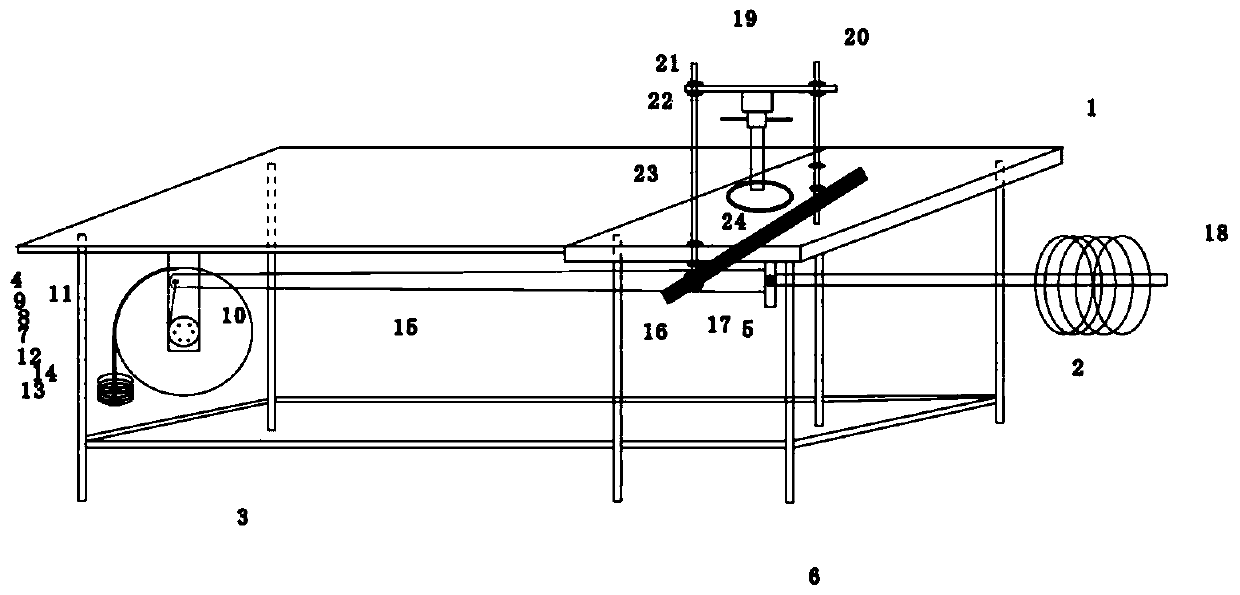

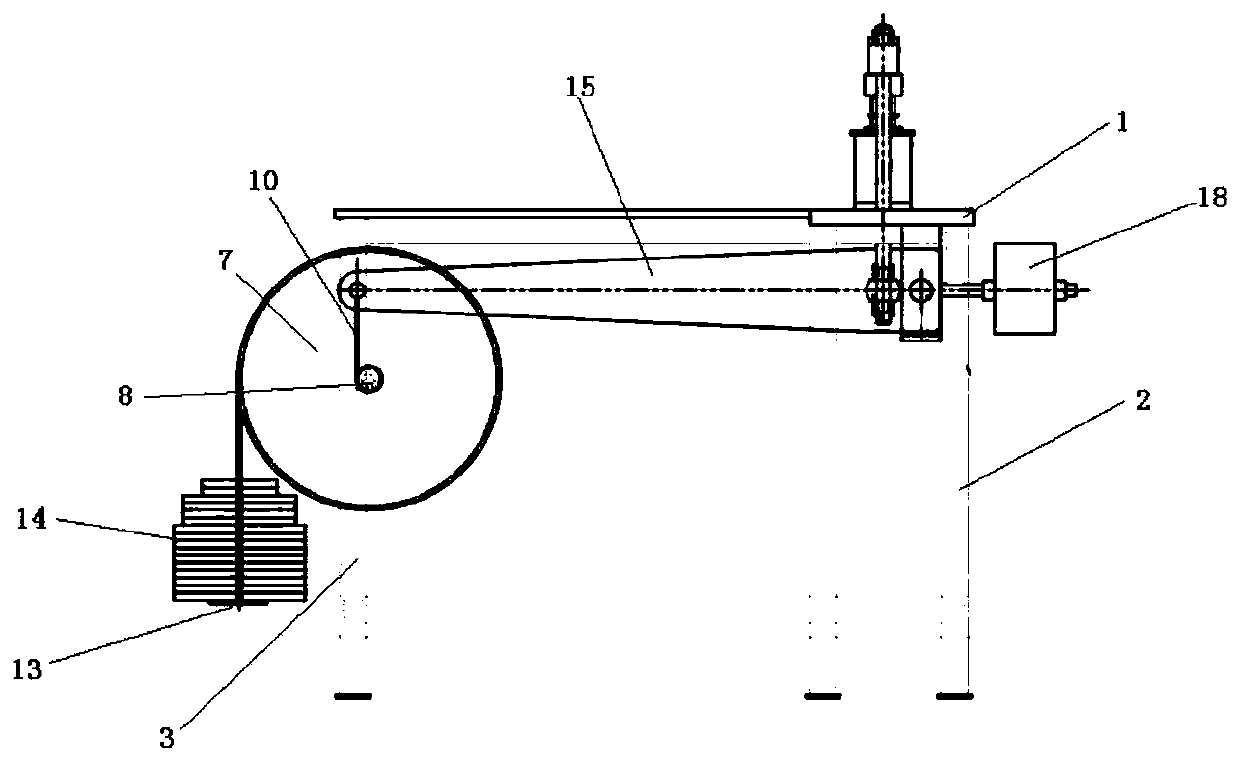

[0033] The device adopted by the invention to solve the technical problem includes a frame part and a test part. The frame part is provided with a rectangular frame plate 1, and one side of the frame plate 1 is provided with four pillars a2, and the other side is provided with two pillars b3. The support of the rack plate 1 by the column b3 is more stable, and the bottom side of the rack plate 1 close to the position of the column b3 is provided with a wheel fixing part 4 perpendicular to the rack plate 1, and one side of the wheel fixing part 4 is arranged in parallel. The roulette 7 and the small roulette 8, and the big roulette 7 and the small roulette 8 are fixed on the roulette fixing part 4 through the shaft, and the axis is perpendicular to the big roulette 7 through the line connecting the center of the circle, and the big roulette 7 and the small roulette 8 is connected by a large bolt 9, the large roulette 7 and the small roulette 8 can rotate and the rotation angles...

Embodiment 2

[0035]Pressure-related calculations for rock samples:

[0036] The radius ratio of the large wheel to the small wheel is 10:1; the leverage ratio is 15:1; the lever and wheel set can amplify the force by 150 times.

[0037] For example: the diameter of the rock sample is 50mm, and the weight is 80kg.

[0038] The pressure obtained for the rock sample is:

[0039] Calculation principles related to instrument design:

[0040] 1. 40Cr steel quenched and tempered diameter ≤ 100mm

[0041] Yield limit 550MPa, safety factor 1.4

[0042] Allowable normal stress:

[0043] Allowable shear stress:

[0044] 2. Spindle:

[0045] (1) Shear strength:

[0046] So d>3.36cm

[0047] (2) Bending strength:

[0048] so

[0049] Namely: ① When l=20cm, d>5.8cm;

[0050] ② When l=25cm, d>6.24cm;

[0051] ③ When l=30cm, d>6.63cm;

[0052] ④ When l=40cm, d>7.3cm.

[0053] A is the cross-sectional area, F is the shear force, W is the axial torsional section modulus; M max is ...

Embodiment 3

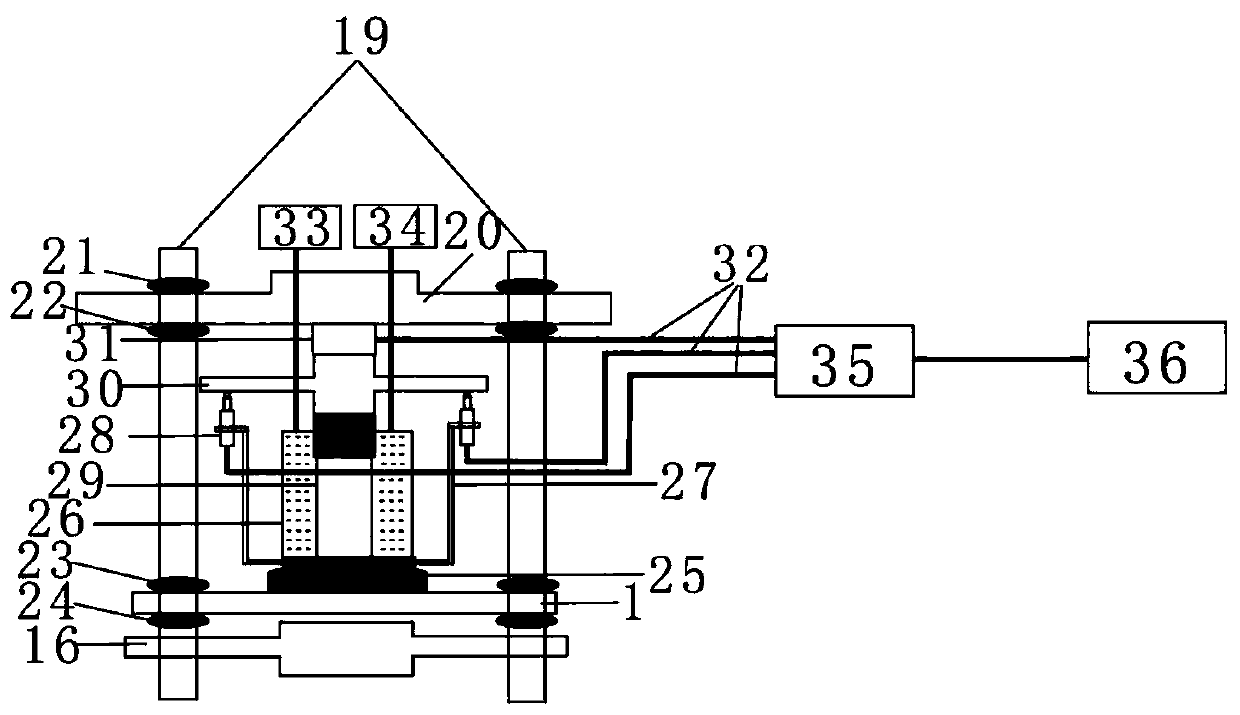

[0097]During the test, the environmental chamber 26 is first placed on the base 25. The contact surface between the base 25 and the environmental chamber 26 is a hemispherical surface, and the balance can be automatically adjusted when the force is applied. Put it on the rock sample 29, adjust the nut b22 to move the beam 20 downward, press the load cell 31 on the rock sample 29, turn the nut a21 downward, and fix the beam 20. Adjust the nut d24 downward, and then adjust the nut c23 upward. The distance between the nut c23 and the rack plate 1 is about 3mm. Adjust the balance weight 18 to balance the lever 15, and finally adjust the nut d24 to make it contact with the bottom of the rack plate 1. touch. Open the acquisition instrument 35 and the computer 36 to display the interface of the load sensor 31 and the size of the LVDT28, then put the LVDT28 fixed on the LVDT frame 27 on the indenter 30, adjust the LVDT28 to the measurable range by the data displayed by the computer 36...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com