Real-time control system for production field

A real-time control system and on-site technology, applied in the general control system, control/regulation system, program control, etc., can solve the problems of low efficiency of the control system, unable to meet the growing production demand, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

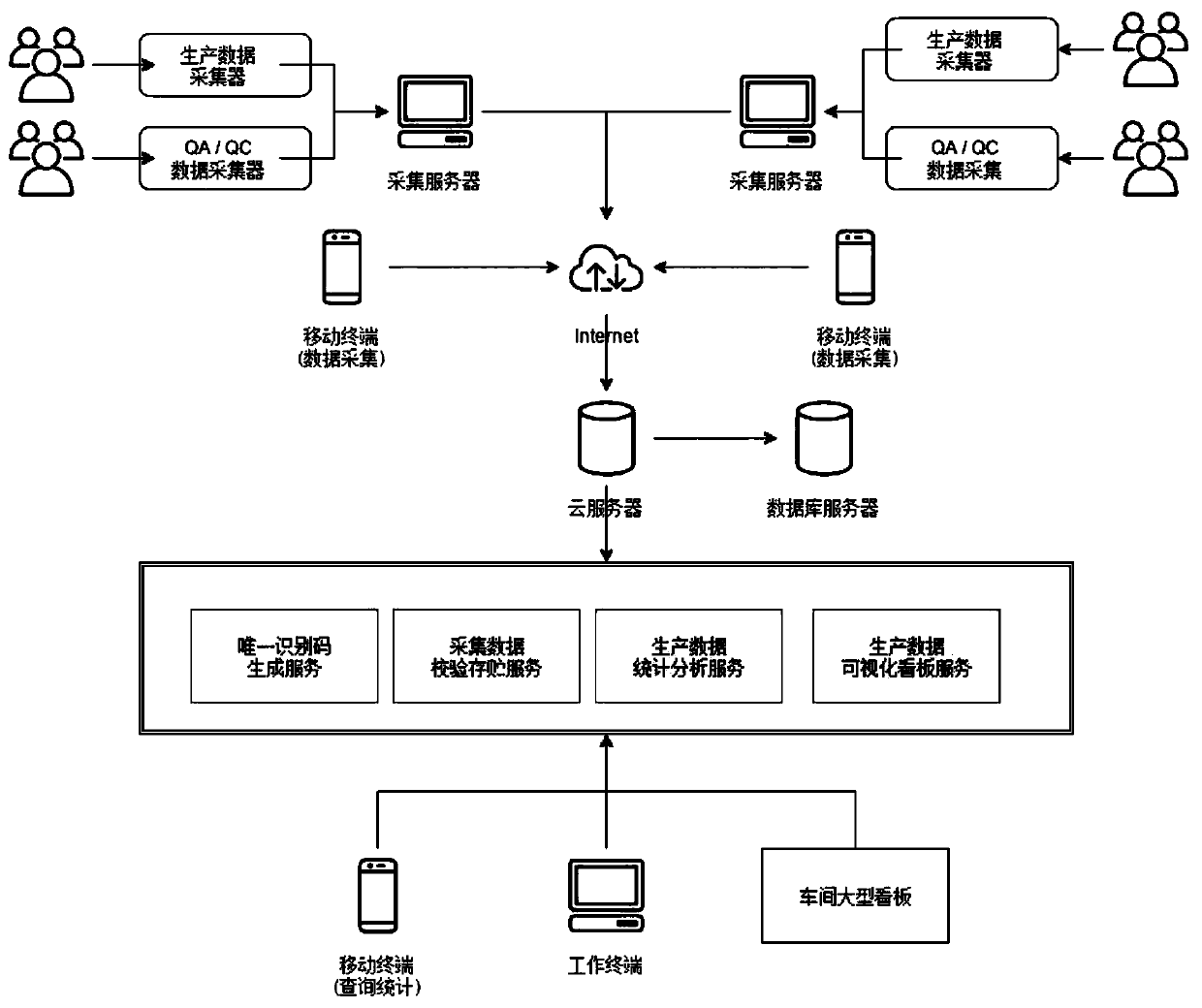

[0021] Such as figure 1 A production site real-time control system is shown, including production data collectors connected through the network, collection servers, cloud servers, control centers and large workshop kanbans. Wherein, the production data collector is installed in the production station and connected with the collection server, used to read employee information and production information, and receive and display information processing results; the collection server is used to use the production data collector's After the data is processed, it is sent to the cloud server through the network; the cloud server is used to send the data it receives to the control center for processing; the control center includes a unique identification code generation service module, a data collection verification storage service module, The production data statistical analysis service module and the production data visualization kanban service module, the unique identification code ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com