Chlorine dioxide preparation device and method

A chlorine dioxide and preparation device technology, applied in the directions of chlorine dioxide, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low purity of chlorine dioxide products, high production cost of chlorine dioxide, low production yield and the like , to reduce the probability of decomposition into chlorine, prevent the output and concentration from being too high, and improve the purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

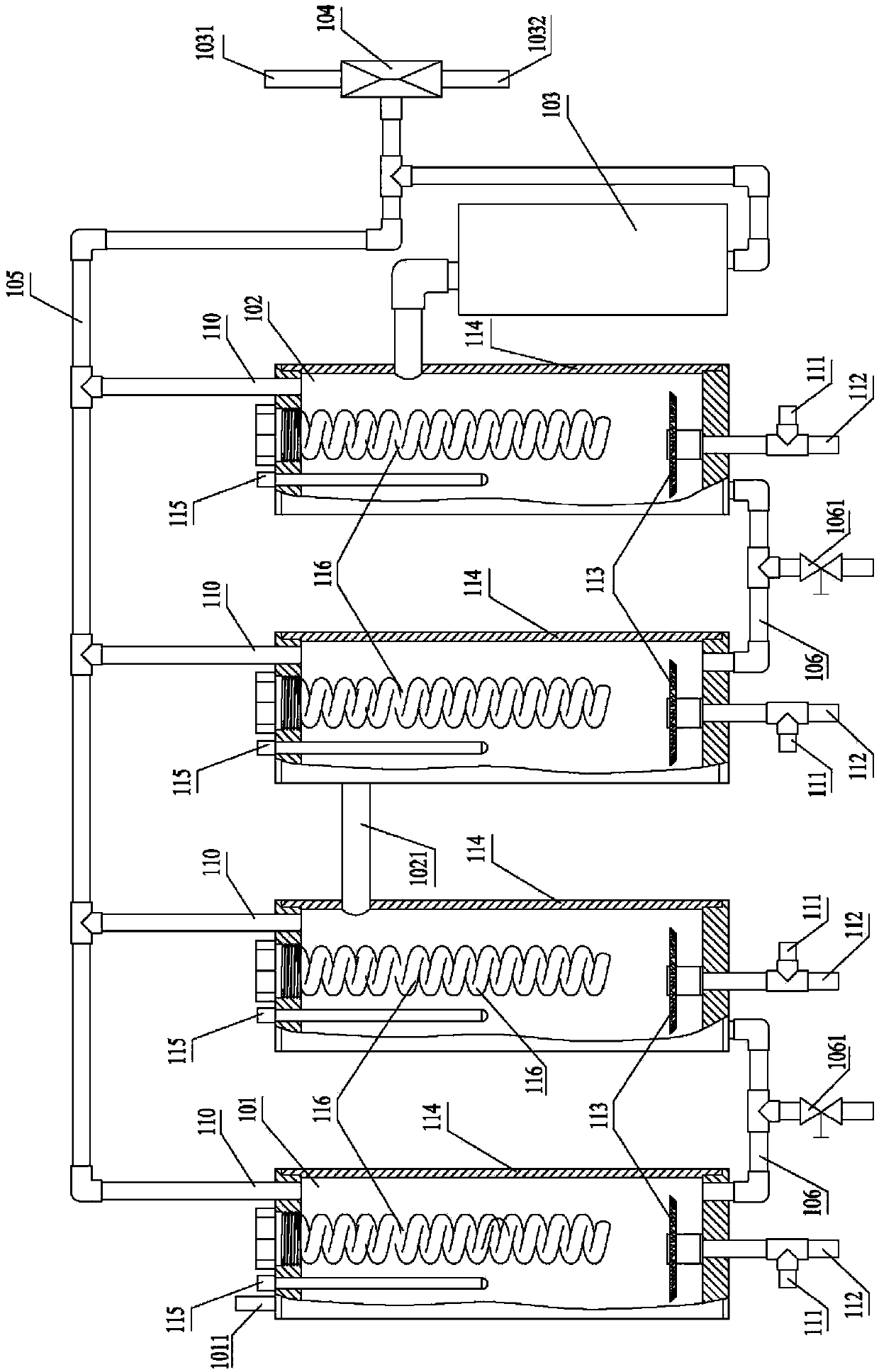

[0045] Please refer to figure 1 , Embodiment 1 of the present application provides a chlorine dioxide preparation device, comprising:

[0046] The input tubular reactor 101 includes a raw material inlet 1011, and the input tubular reactor 101 is used to input the main reaction raw materials for preparing chlorine dioxide;

[0047] The output tubular reactor 102 includes a material overflow pipe 1021, and the output tubular reactor 102 is used for outputting reaction materials;

[0048] The addition reactor 103 includes a reaction chamber connected to the material overflow pipe 1021 for receiving the material overflowing from the tubular reactor and continuing to react in the reaction chamber to generate chlorine dioxide;

[0049] The water ejector 104 is communicated with the addition reactor 103, and includes a power water pipe 1031 and an outlet pipe 1032 for an aqueous chlorine dioxide solution. Pipe 1032 is used to output chlorine dioxide aqueous solution;

[0050] Wher...

Embodiment 2

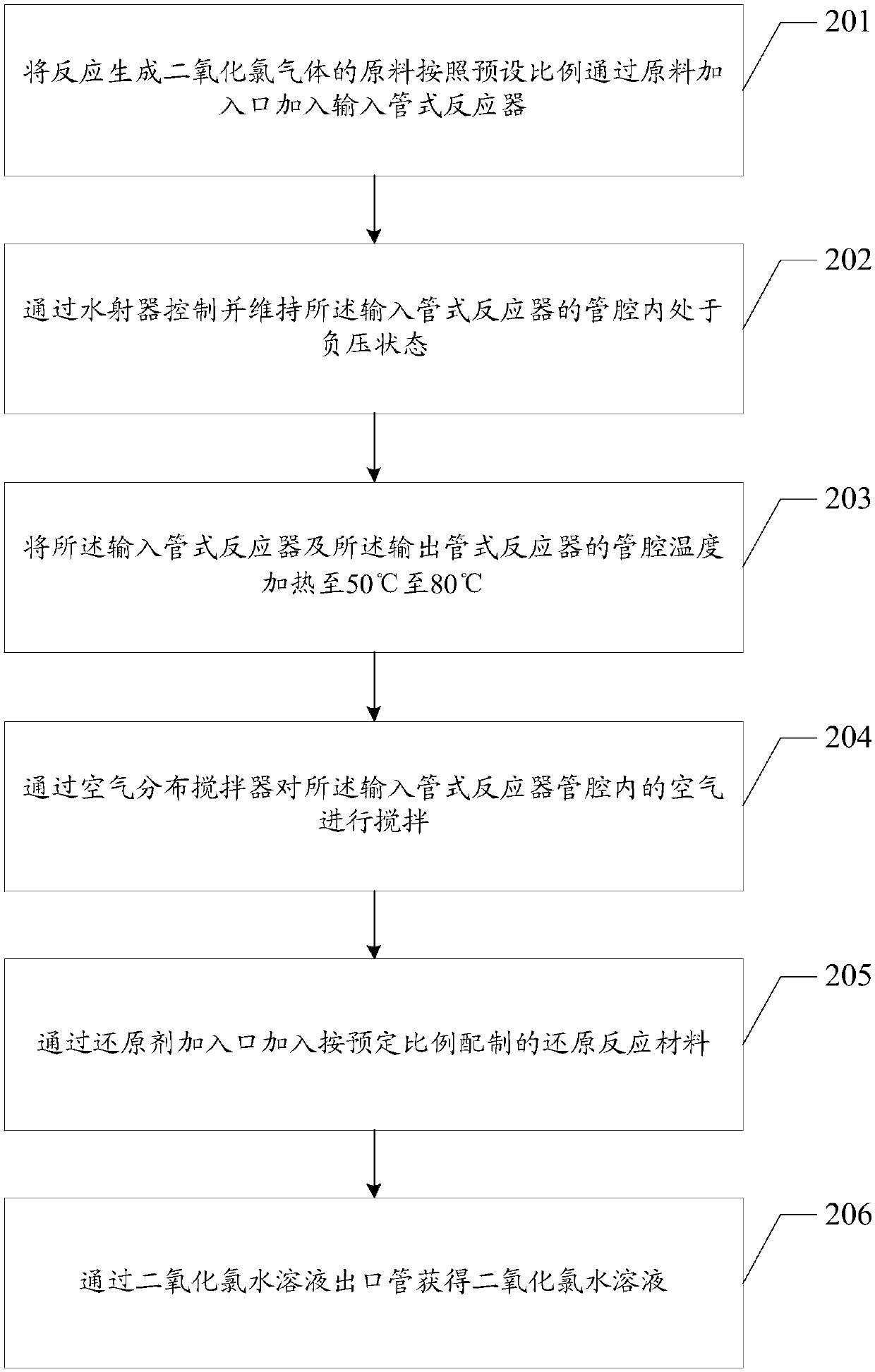

[0057] Please refer to figure 2 , the embodiment of the present application provides a chlorine dioxide production method, which is applied to the chlorine dioxide production device as described in Example 1, including:

[0058] Step 201: Adding the raw materials for reaction to generate chlorine dioxide gas into the tubular reactor through the raw material inlet according to the preset ratio;

[0059] Step 202: Control and maintain a negative pressure in the lumen of the input tubular reactor through a water injector;

[0060] Step 203: Heat the lumen temperature of the input tubular reactor and the output tubular reactor to 50°C to 80°C; and when the input tubular reactor and output tubular reactor of the chlorine dioxide preparation device When the outer tube wall of the reactor and the intermediate tubular reactor is covered with an electric heating cable, the outer tube wall can be heated by the electric heating belt, so that the temperature of the tube cavity is heated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com