Life prediction method suitable for various cyclic loads

A cyclic load and life prediction technology, applied in the fields of instrumentation, electrical digital data processing, informatics, etc., can solve the problem of lack of consideration of the variability of holding load stress, and achieve the effect of simple and easy operation and accurate cycle life prediction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

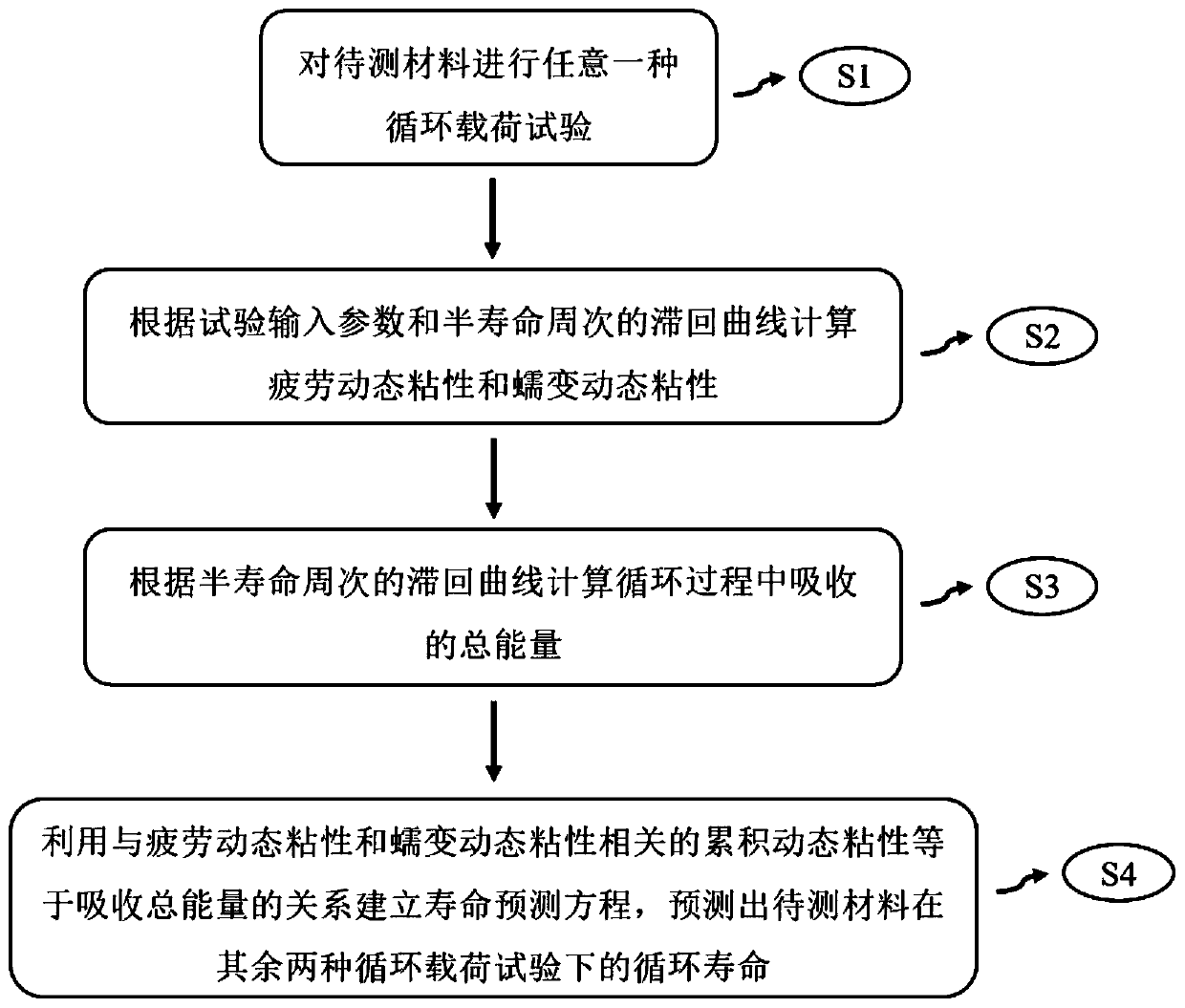

Method used

Image

Examples

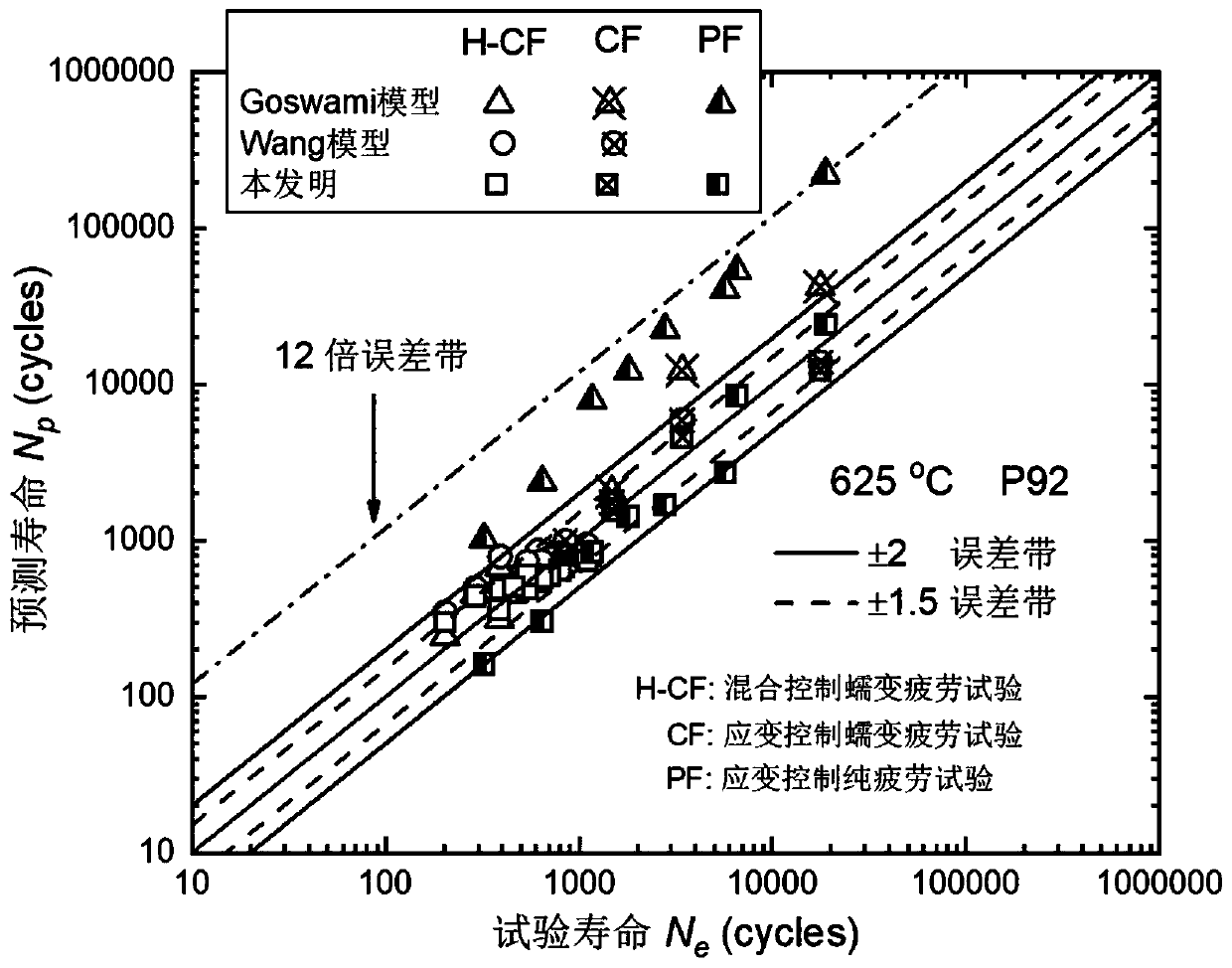

Embodiment 1

[0056] Table 1 is the test data of P92 steel at 625 °C, and the strain rate is 1×10 -3 . These include 5 sets of strain-controlled pure fatigue tests with strain amplitudes ranging from 0.5% to 1.6%, and 12 sets of stress-strain mixed-controlled creep fatigue tests. In order to further verify the life prediction ability of the model at different strain rates, a Zhang published a paper [Zhang SL, Xuan FZ. Interaction of cyclic softening and stress relaxation of 9–12% Crsteel under strain-controlled fatigue-creep condition: experimental and modeling. International Journal of Plasticity 2017; 98:45-64.] Seven sets of strain-controlled fatigue and creep fatigue data of P92 steel at 625°C with a strain rate of 2×10 -3 .

[0057] First calculate the fatigue dynamic viscosity v according to step S2 of the life prediction method of the present invention d-f and creep dynamic viscosity v d-c , and then calculate the total energy ΣW absorbed during the cycle according to step S3 of ...

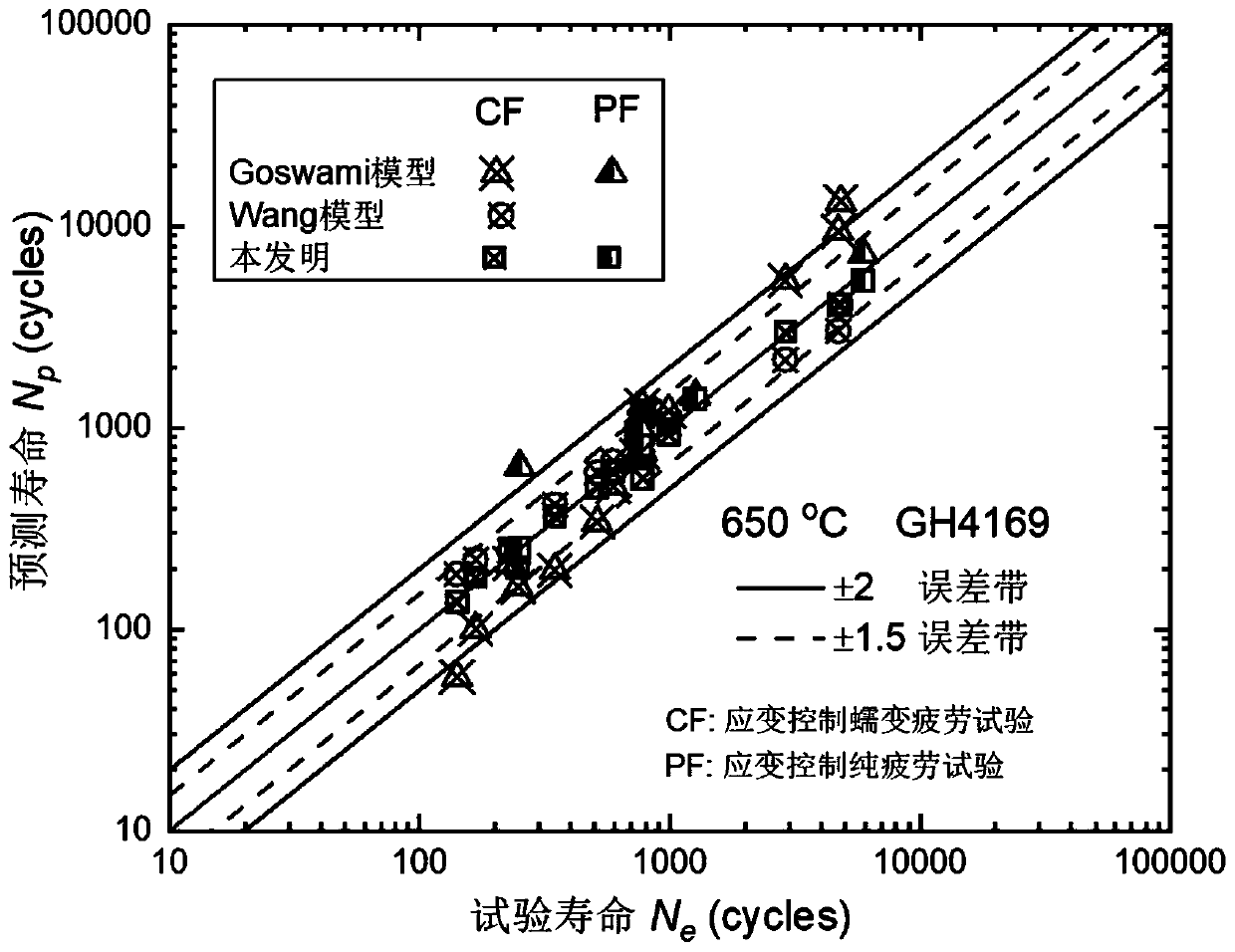

Embodiment 2

[0062] The selected data are the test results of GH4169 alloy at 650°C in Wang Runzi’s doctoral thesis [Wang Runzi. Creep-fatigue life prediction model and application based on energy density dissipation criterion. Doctoral thesis. East China University of Science and Technology (2019)]. These include 4 sets of strain-controlled pure fatigue tests with strain amplitudes ranging from 1% to 2%, and 14 sets of strain-controlled creep fatigue tests.

[0063] First calculate the fatigue dynamic viscosity v according to step S2 of the life prediction method of the present invention d-f and creep dynamic viscosity v d-c , and then calculate the total energy ΣW absorbed during the cycle according to step S3 of the life prediction method of the present invention. Finally, a life prediction equation is established according to step S4 of the life prediction method of the present invention. Among them, according to the test data of the strain-controlled pure fatigue test, it is obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com