Topological optimization design method considering self-supporting constraints of additive manufacturing structure

A topology optimization and design method technology, applied in design optimization/simulation, comprehensive factory control, etc., can solve problems such as optimality of damaged structures, increased design difficulty, increased processing time and cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

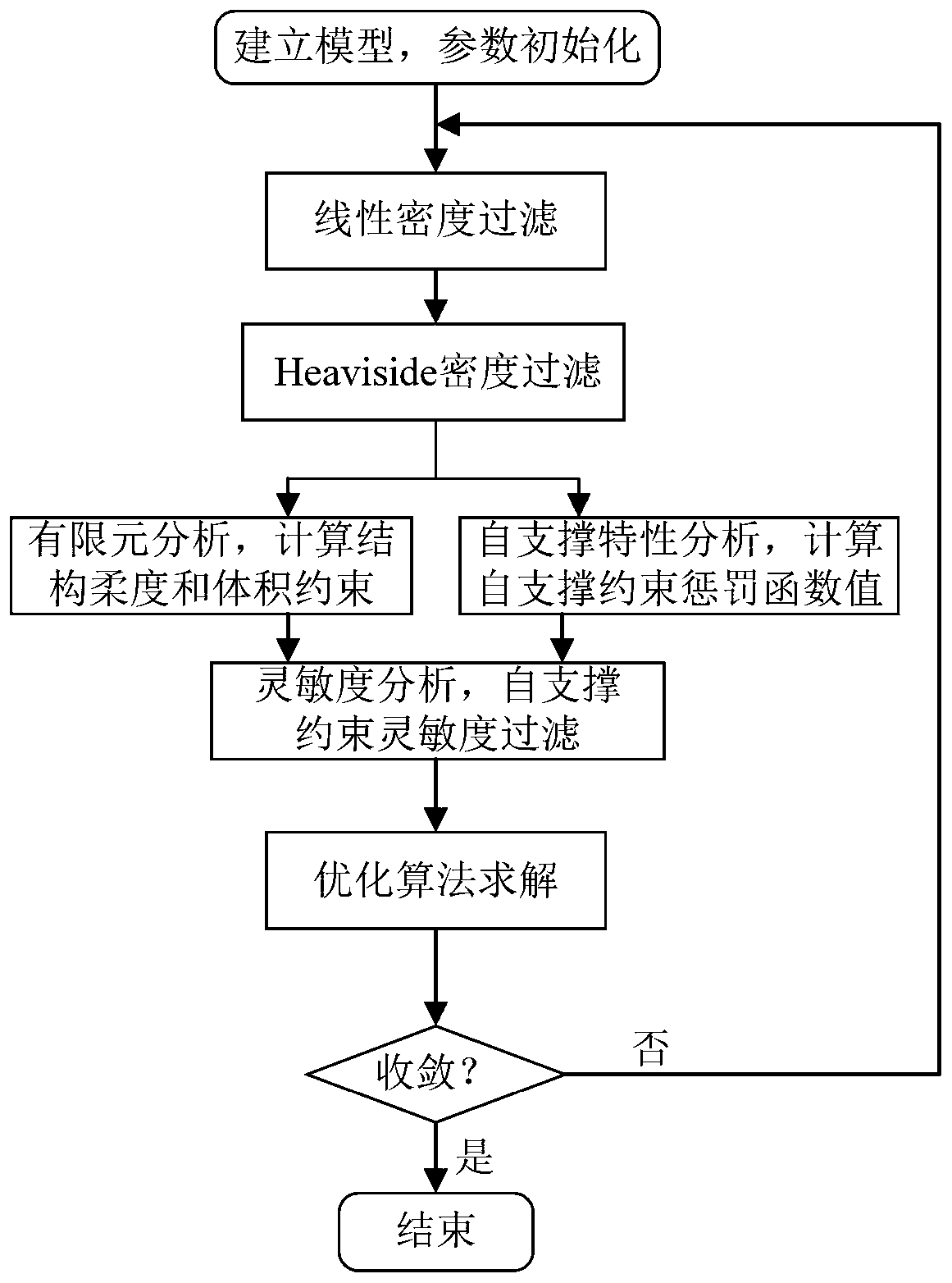

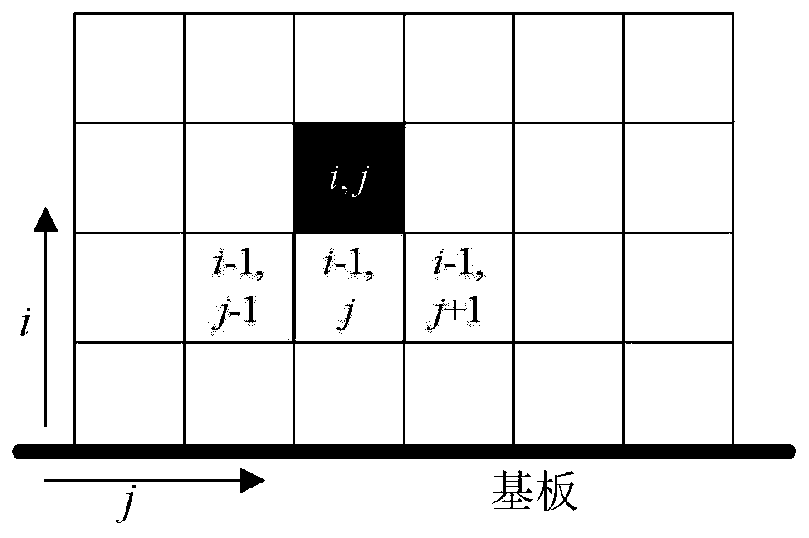

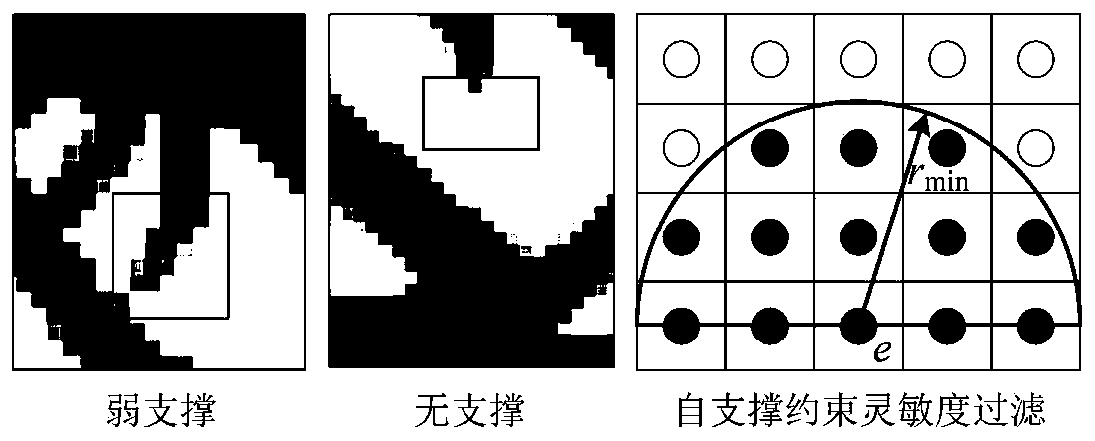

[0074] Such as figure 1 As shown, the topology optimization design method considering the self-supporting constraints of the additive manufacturing structure provided by the present invention includes the following steps in order:

[0075] 1) Establish an optimization model, define geometric models, loads and boundary conditions, define design variables, objective functions and constraints based on the SIMP method framework, and perform cell density, material property parameters, structural volume ratio constraints, structural self-supporting penalty functions, Optimize algorithm parameters to set;

[0076] Specific steps are as follows:

[0077] Based on the framework of the SIMP method, with the minimum structural flexibility as the optimization goal, the discretized unit relative density as the design variable, and the structural volume ratio constraint and the structural self-supporting constraint penalty function value as the constraint conditions, an optimization model ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com