Lamellar discharge valve

A discharge valve, reed type technology, applied in the field of reed valves, can solve the problem of reduced service life of reed 1

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Spatial specifications such as top, bottom, side or the like relate to the description of the reed discharge valve, which, as shown in the illustration, is arranged above the compression cylinder and whose reed Also move upwards as shown in the illustration. But these descriptions are not limiting.

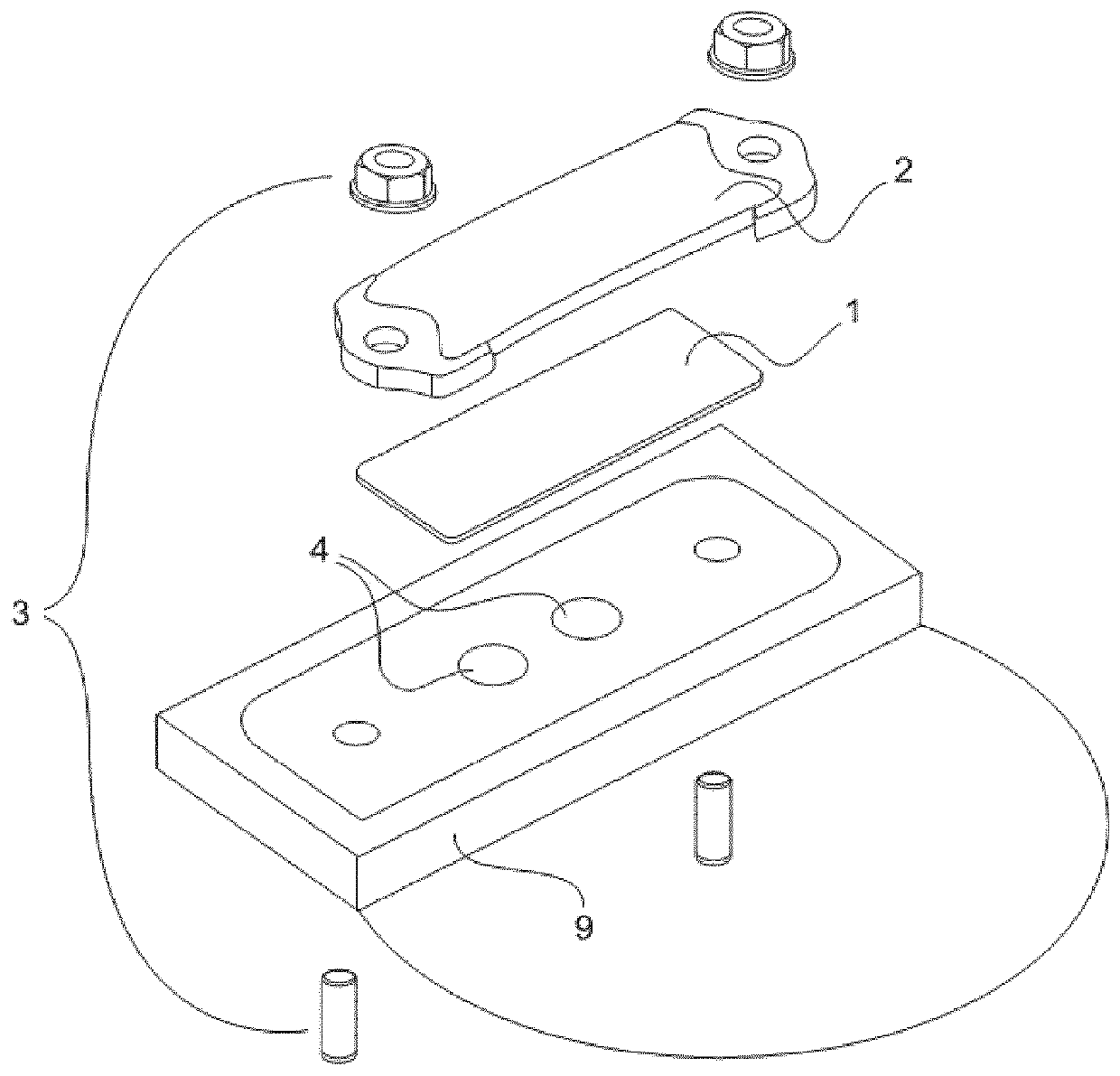

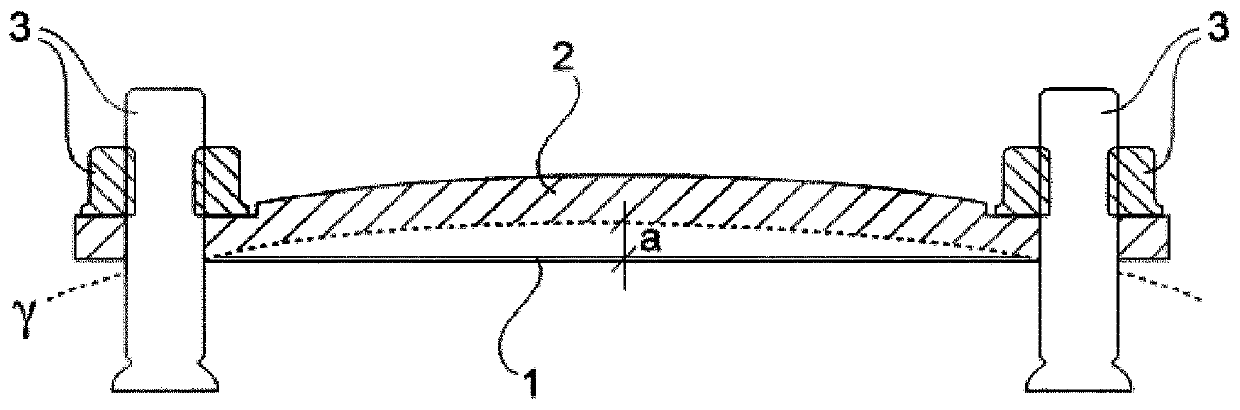

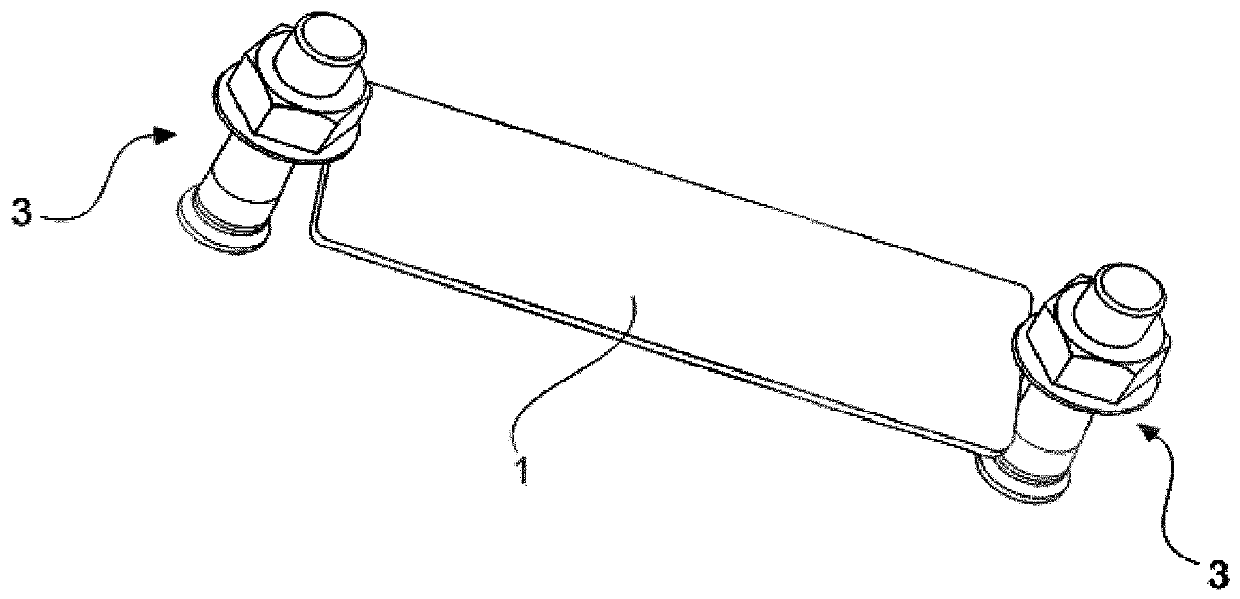

[0031] Figure 3a shows a side sectional view of a reed discharge valve according to a first embodiment of the present invention, Figure 3b An isometric view of a reed discharge valve according to a first embodiment of the invention is shown. A reed discharge valve is provided as a housing for closing and opening the compression cylinder of the compressor ( figure 1 : discharge opening ( figure 1 : reference numeral 4).

[0032] If according to figure 1 , 2a Like the prior art of 2b, according to Figure 3a and 3b The embodiment of the reed discharge valve also has a discharge opening for closing and opening not shown here ( figure 1 : the reed 1 of reference num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com