Method for completely eliminating cooling tower plume mist

A technology that completely eliminates and cools towers. It is applied in the direction of water shower coolers, energy industry, and climate sustainability. It can solve the problems of incomplete defogging effect, increased total tower height, and low water saving rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

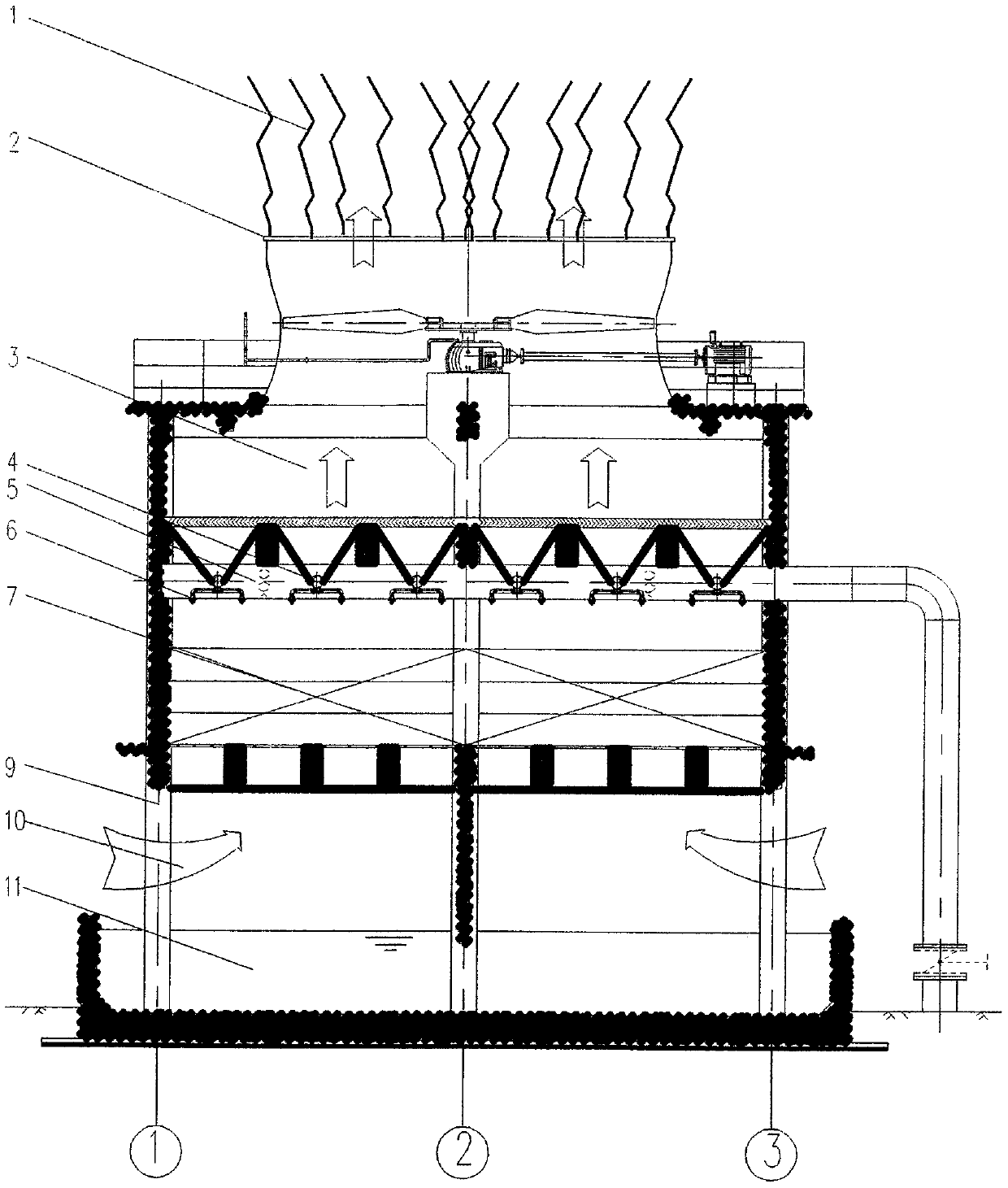

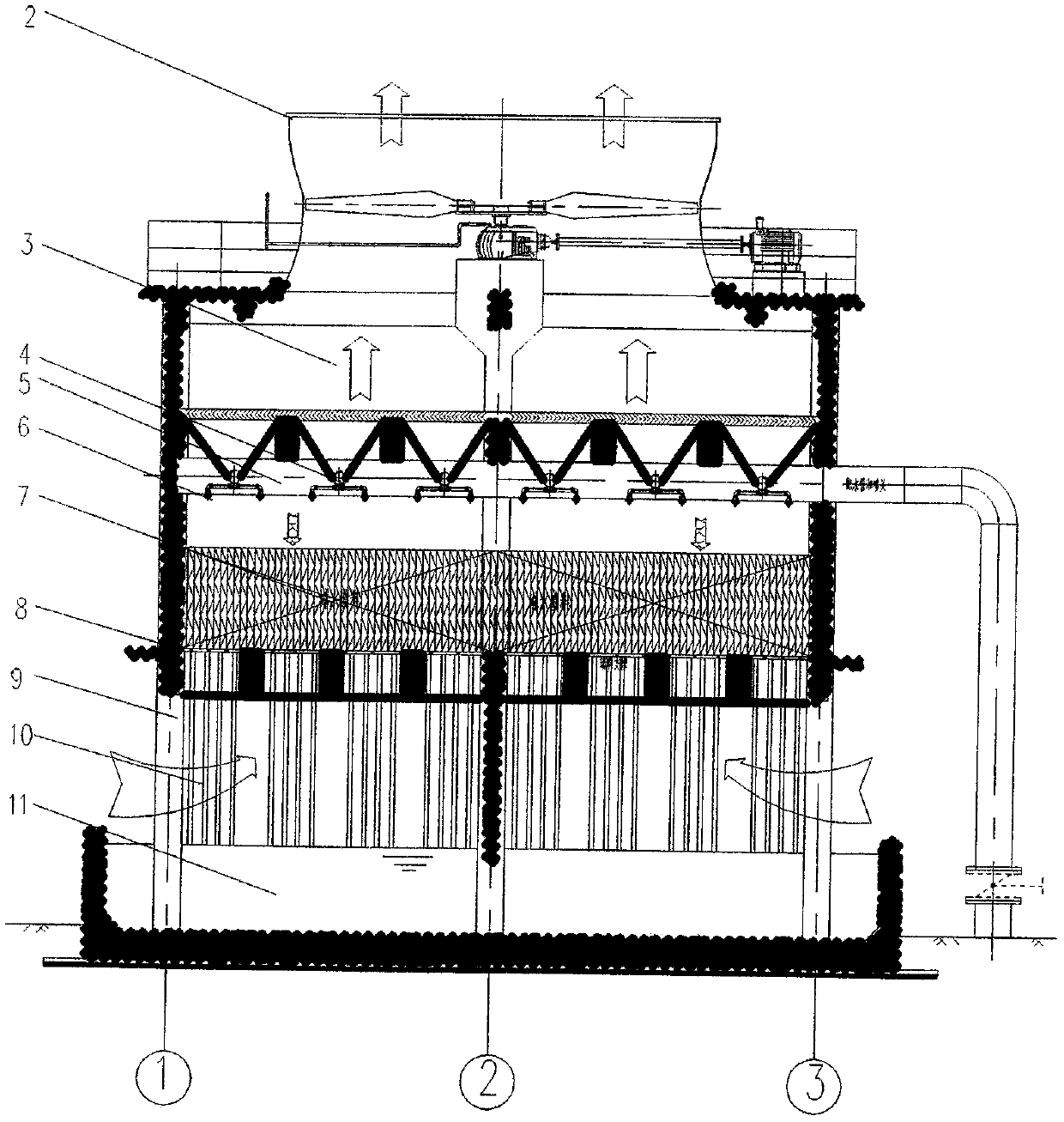

[0021] For the entire tower group with multiple towers, when winter comes, the winter operation mode will be gradually turned on. When opening each tower, adjust the water distribution system 4 and the spray system 6, so that the water spraying interval passes through the gap of the packing 7, and the cooling of the spraying water does not directly convect with the dry cold air 10 entering the tower. The water is scattered through the sump pipe 9 and enters the sump 11. The hot water 5 entering the tower is never in contact with the air. The dry cold air 10 entering the tower becomes dry hot air and leaves the outlet 2 of the cooling tower. No production is produced during the cooling process of hot water. Out of Feather Mist1. At the end of winter, the summer mode of some towers in the tower group will be turned on one after another, and as the weather gets warmer and hotter, until all of them return to the summer mode.

Embodiment 2

[0023] For single-room towers, turn on the winter operation mode for some areas inside the tower. In the part of winter mode, adjust the water distribution system 4 and the sprinkler system 6, so that the water spray interval passes through the gap of the packing 7, the cooling of the spray water does not directly convect with the dry cold air 10 entering the tower, and it is at the lower part of the packing 7 or the upper part of the air inlet 8 The water is scattered into the sump 11 through the sump pipe 9, the hot water 5 entering the tower is never in contact with the air, and the dry cold air 10 entering the tower becomes hot and dry air; in the part where the winter mode is not turned on, hot and humid air 3 is still generated. After the air of the two modes is mixed, when leaving the air outlet 2 of the cooling tower, the fog concentration is very low or the plume 1 is not seen. At the end of winter, the summer mode of some parts of the tower will be turned on one afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com