Bone drill bit and base mounting method

A bone and drill technology, applied in the field of medical devices, can solve the problems of easy deformation of the base, achieve long-term effective fixation, improve stability, and facilitate incision healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

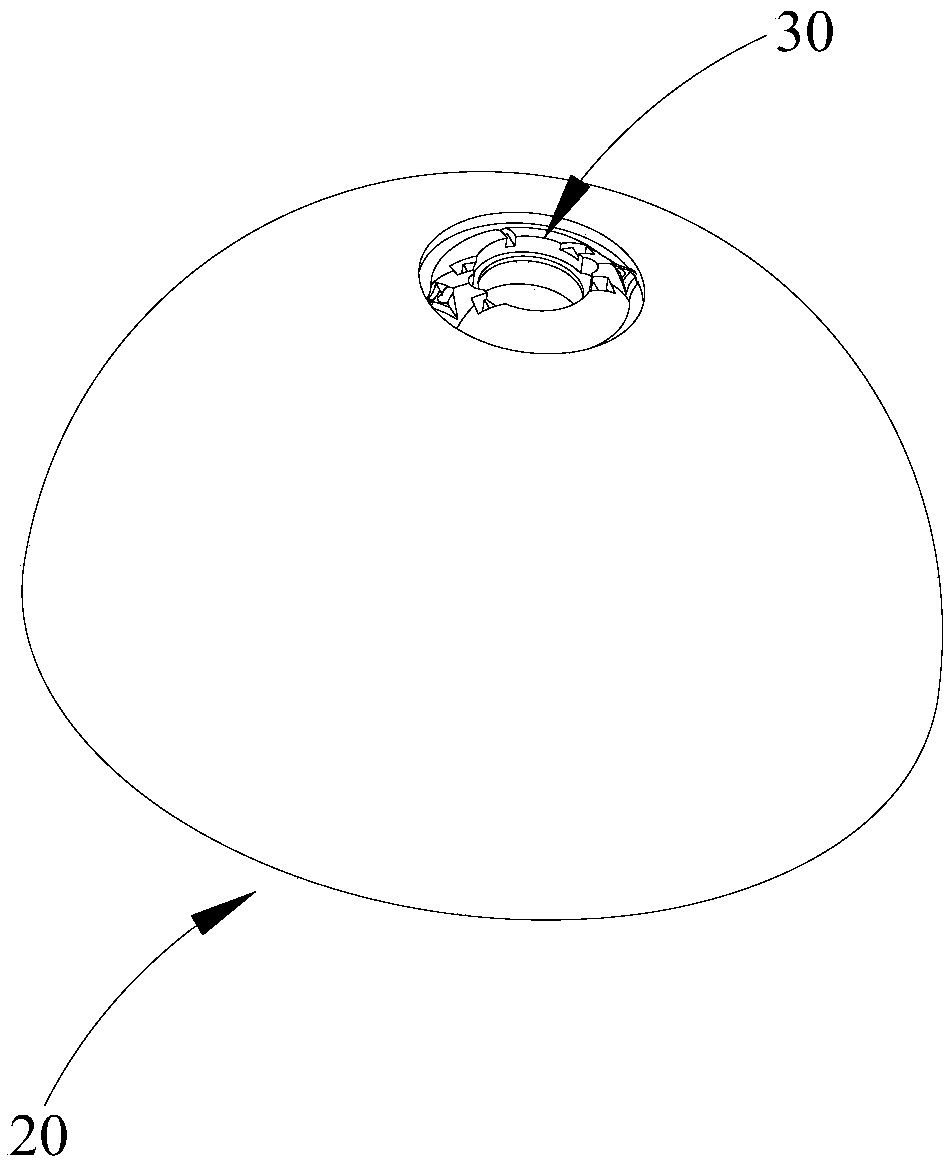

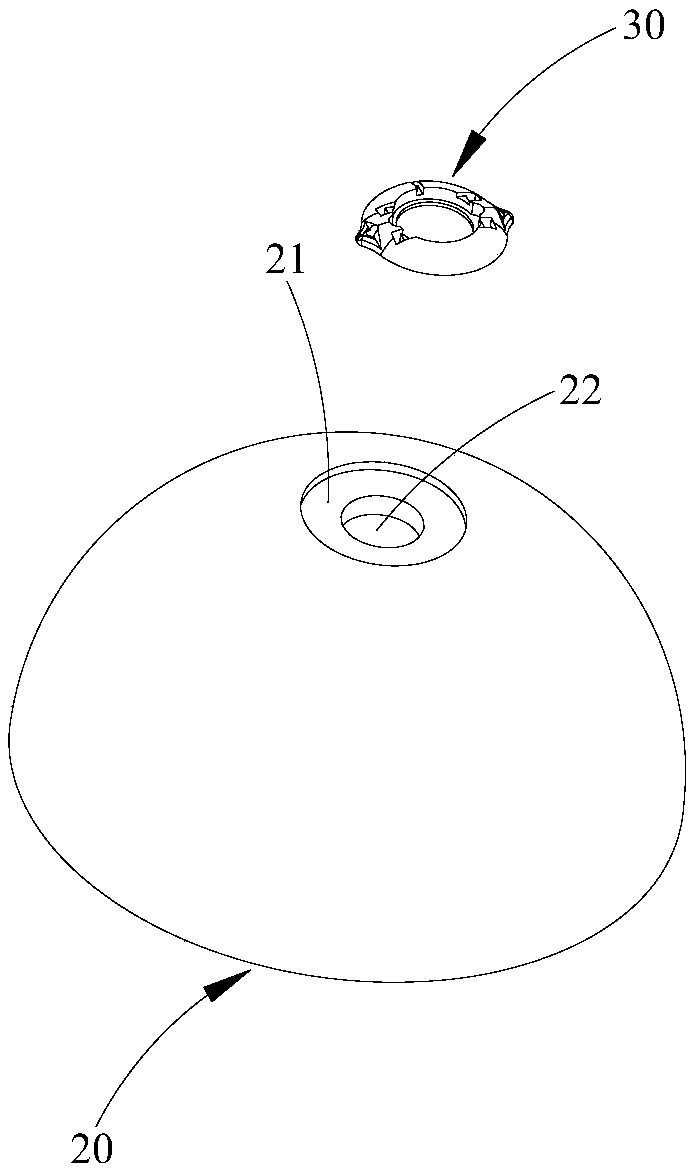

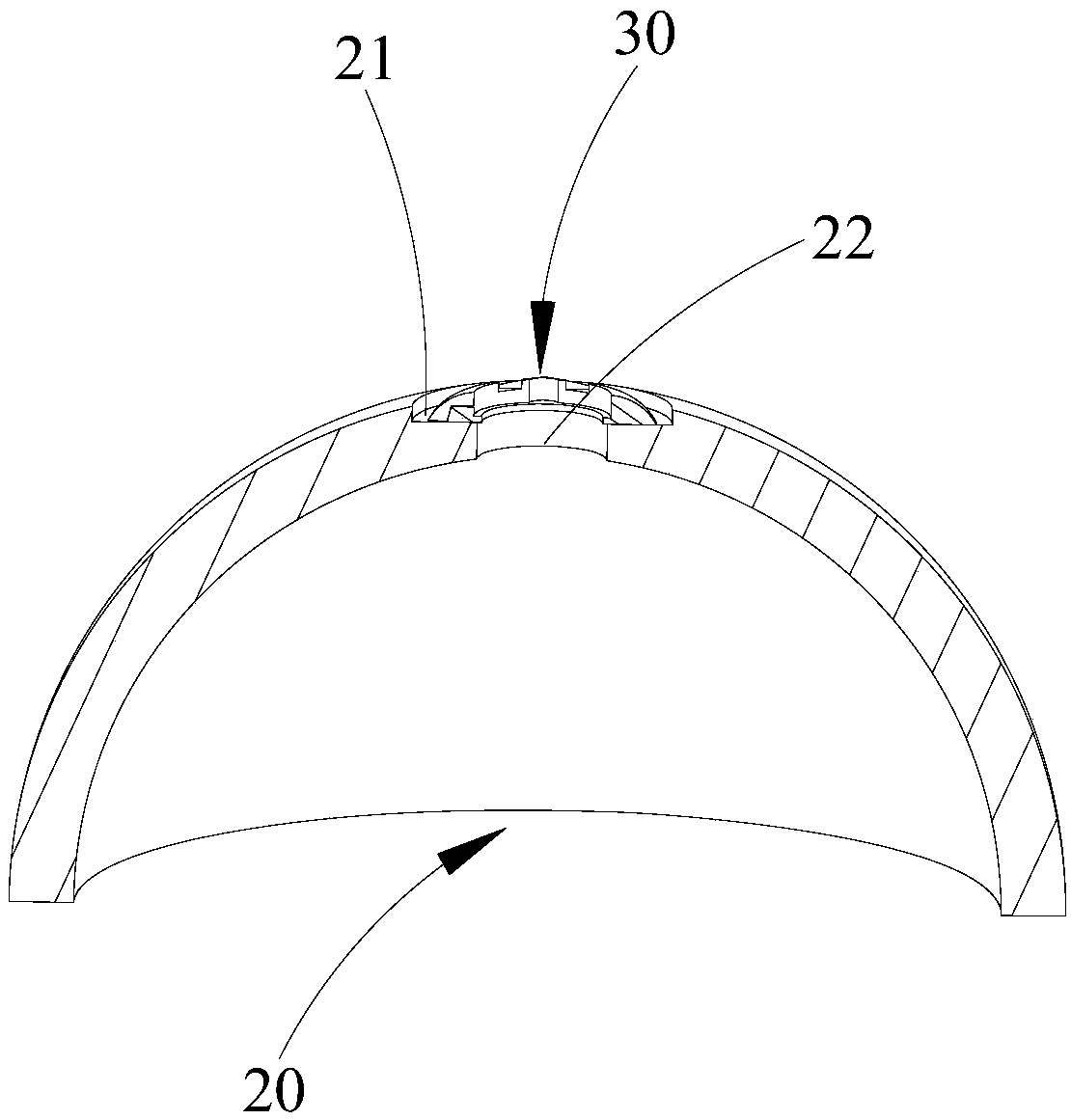

[0098] A bone drill bit 10 includes a positioning component 11 and a milling component 12 .

[0099] The positioning assembly 11 includes a positioning boss 111, which is used to be arranged in the pre-opened installation hole 22 of the skull 20, and the diameter of the positioning boss 111 is 10mm-16mm.

[0100] The milling assembly 12 includes a milling edge 121 and a clamping portion 122. The milling edge 121 includes a first bottom plate 1211 and a plurality of first blades 1212. The clamping portion 122 and the positioning boss 111 are respectively arranged on opposite side surfaces of the first bottom plate 1211. . For the convenience of description, the opposite side surfaces of the first base plate 1211 are respectively marked as the upper surface of the first base plate and the lower surface of the first base plate, wherein the clamping portion 122 is connected to the upper surface of the first base plate, and the positioning boss 111 is located on the first base plat...

Embodiment 2

[0103] A bone drill bit 10 includes a positioning component 11 and a milling component 12 .

[0104] The positioning assembly 11 includes a positioning boss 111, which is used to be arranged in the pre-opened installation hole 22 of the skull 20, and the diameter of the positioning boss 111 is 10mm-16mm.

[0105] The milling assembly 12 includes a milling edge 121 and a clamping portion 122. The milling edge 121 includes a first bottom plate 1211 and a plurality of first blades 1212. The clamping portion 122 and the positioning boss 111 are respectively arranged on opposite side surfaces of the first bottom plate 1211. . For the convenience of description, the opposite side surfaces of the first base plate 1211 are respectively marked as the upper surface of the first base plate and the lower surface of the first base plate, wherein the clamping portion 122 is connected to the upper surface of the first base plate, and the positioning boss 111 is located on the first base plat...

Embodiment 4

[0115] A bone drill bit 10 includes a positioning component 11 and a milling component 12 .

[0116] The positioning assembly 11 includes a positioning boss 111, which is used to be arranged in the pre-opened installation hole 22 of the skull 20, and the diameter of the positioning boss 111 is 10mm-16mm.

[0117] The milling assembly 12 includes a milling edge 121 and a clamping portion 122. The milling edge 121 includes a first bottom plate 1211 and a plurality of first blades 1212. The clamping portion 122 and the positioning boss 111 are respectively arranged on opposite side surfaces of the first bottom plate 1211. . For the convenience of description, the opposite side surfaces of the first base plate 1211 are respectively marked as the upper surface of the first base plate and the lower surface of the first base plate, wherein the clamping portion 122 is connected to the upper surface of the first base plate, and the positioning boss 111 is located on the first base plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com